A pe bellows

A corrugated pipe and inner corrugated pipe technology, applied in the field of PE corrugated pipe, can solve the problems of water seepage hole damage, inner wall corrosion of water seepage hole, water accumulation on expressways, etc., to prevent extrusion wear, increase the effect of breaking and speed up The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

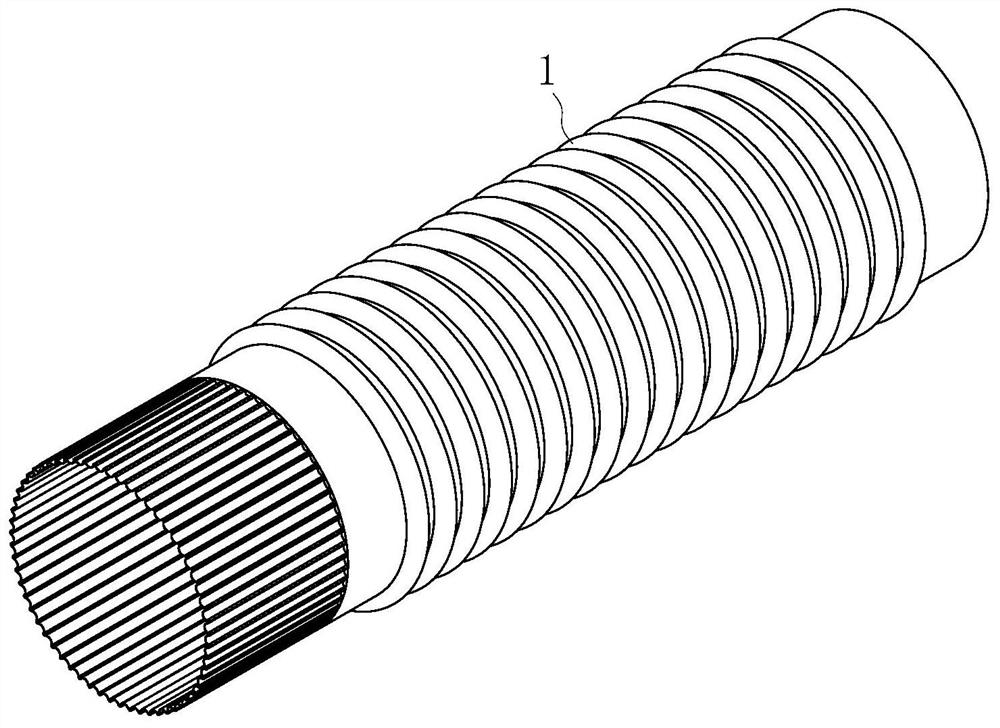

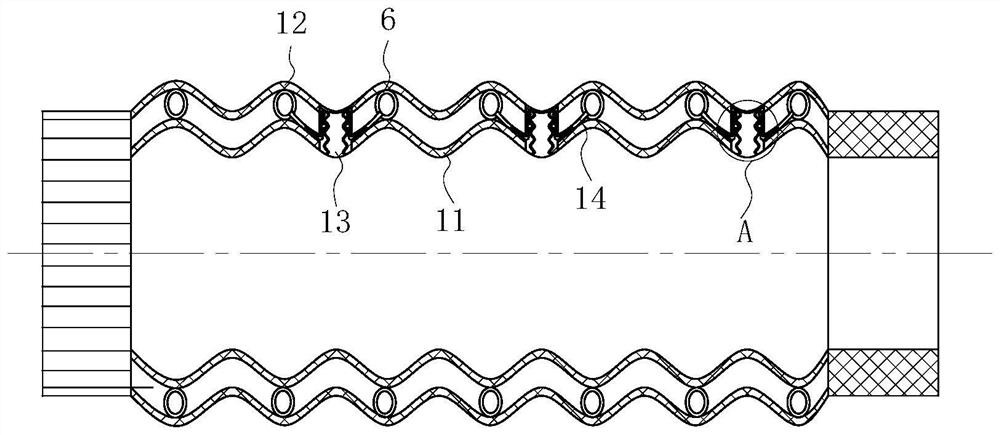

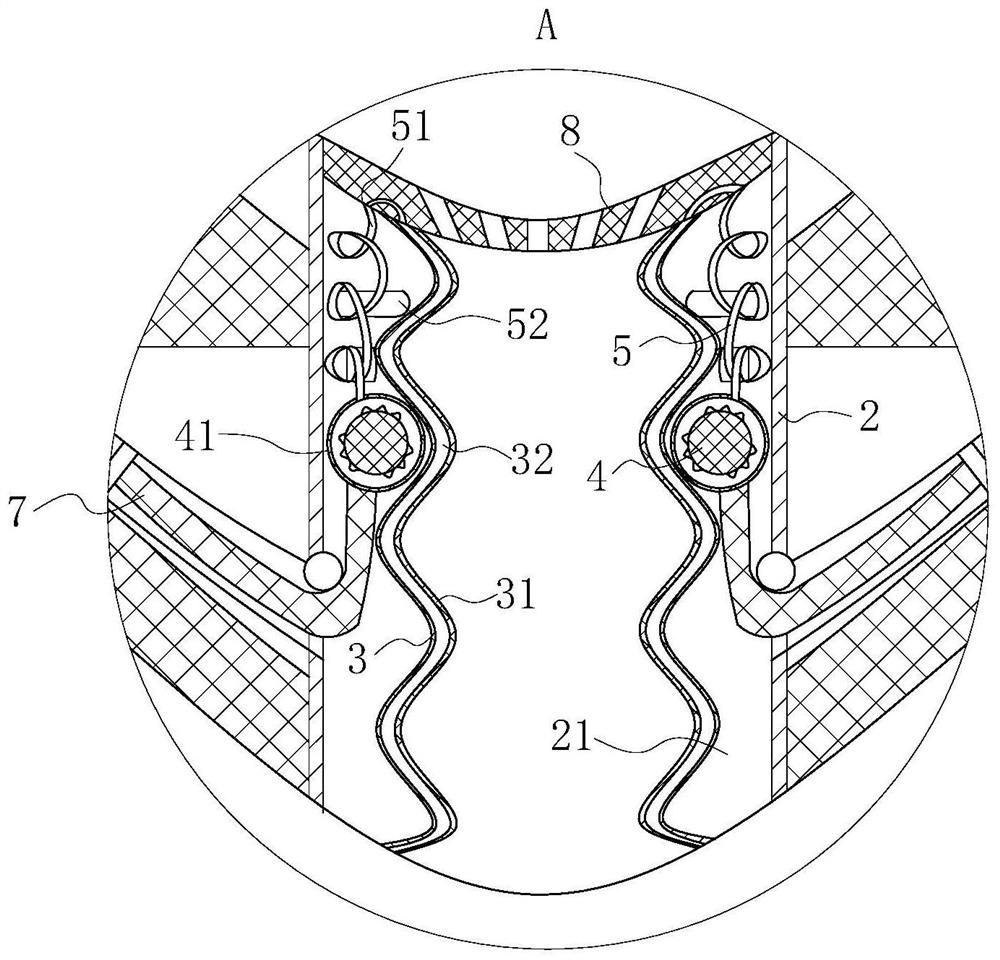

[0022] use Figure 1-Figure 5 A PE corrugated pipe according to one embodiment of the present invention will be described below.

[0023] Such as figure 1 , figure 2 with image 3As shown, a PE bellows according to the present invention includes a bellows body 1: the bellows body 1 is composed of an inner bellows 11 and an outer bellows 12, and the trough of the bellows body 1 is provided with a water seepage A hole 13; the water seepage hole 13 is inserted with a guide tube 2, and an elastic corrugated film 3 is inserted in the guide tube 2, and a sliding cavity 21 is formed between the elastic corrugated film 3 and the guide tube 2; The outer wall of the elastic corrugated film 3 is sleeved with an annular toggle column 4, and the upper end of the annular toggle column 4 is connected to the top of the guide tube 2 through the elastic pull piece 5; the inner bellows 11 and the outer bellows 12 An annular extrusion bag 6 is sleeved between them, and a guide chute 14 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com