A foundation pit drainage structure

A technology of drainage structure and foundation pit, applied in the field of housing construction, can solve the problems of the influence of drainage efficiency and the limited amount of infiltrated water, and achieve the effect of saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

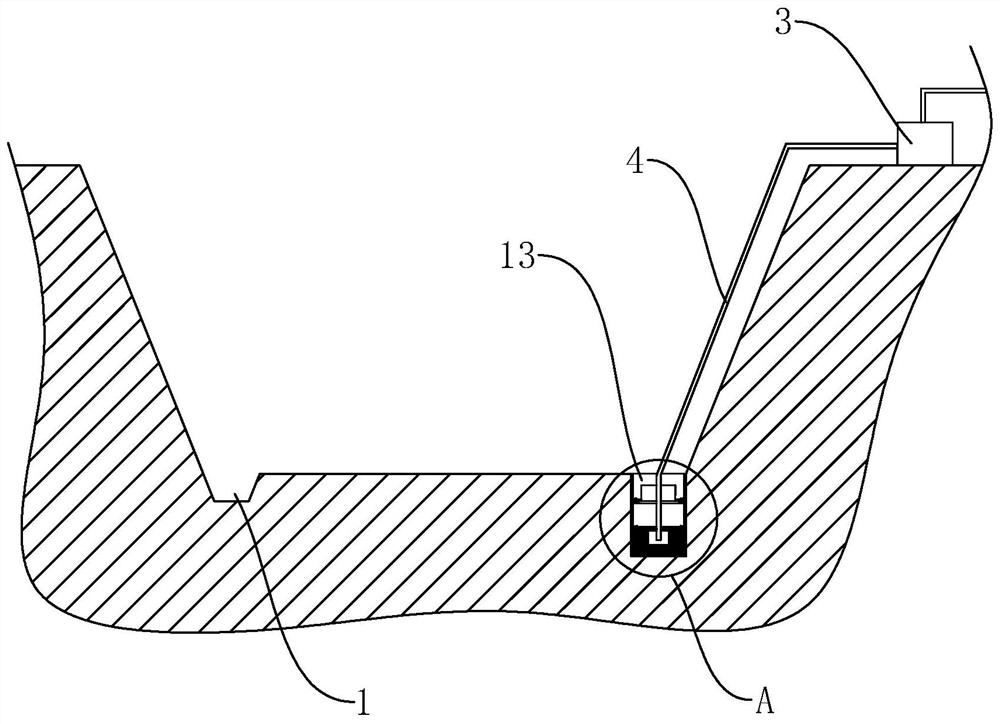

[0039] A foundation pit drainage structure, such as figure 1 As shown, it includes drainage ditches 1 arranged around the bottom of the foundation pit and sump wells 13 arranged at intervals along the drainage ditch 1 , and also includes a suction pump 3 connected to a suction pipe 4 extending into the bottom of the sump wells 13 . The bottom of drainage ditch 1 is lower than the bottom of foundation pit, and the bottom of water collecting well 13 is lower than the bottom of drainage ditch 1. Therefore groundwater and rainwater can flow in the drainage ditch 1, flow in the sump well 13 again, be sucked away by the water pump 3 at last;

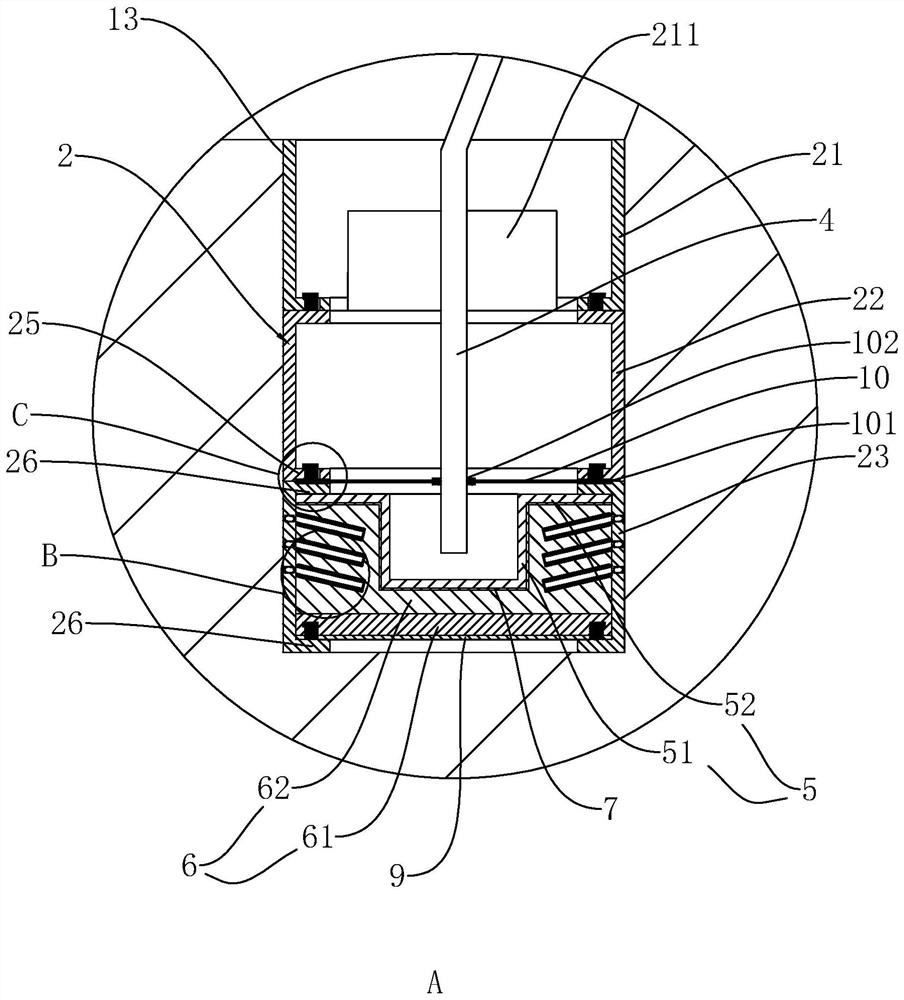

[0040] like figure 2 As shown, in order to prevent problems such as quicksand and collapse due to water seepage in the well wall of the water collection well 13, the inner wall of the water collection well 13 is closely attached to the support pipe 2 whose length is equal to the well depth. The support pipe 2 is divided into jacking pipe 21...

Embodiment 2

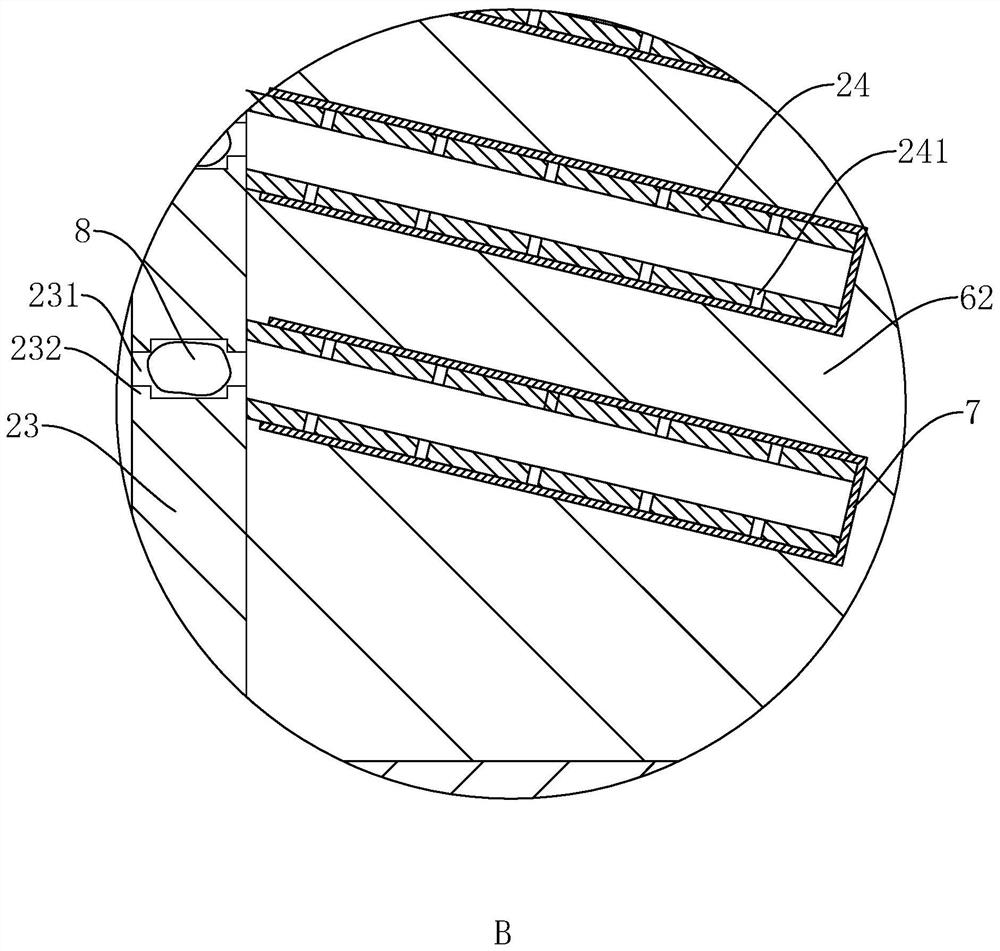

[0049] Different from Embodiment 1, the purification layer 62 includes the following raw materials in parts by weight: 40 parts of activated carbon, 30 parts of fine river sand, 16 parts of diatomaceous earth, and 50 parts of ceramsite filter material.

Embodiment 3

[0051] Different from Embodiment 1, the purification layer 62 includes the following raw materials in parts by weight: 35 parts of activated carbon, 25 parts of fine river sand, 13 parts of diatomaceous earth, and 40 parts of ceramsite filter material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com