A kind of artificial turf with high tuft strength and its preparation process

A technology of artificial turf and preparation process, which is applied to roads, pavements, buildings, etc., can solve problems such as pollution, drop, and many artificial turf preparation processes, and achieve reduced production costs, improved wettability, improved structural stability and The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

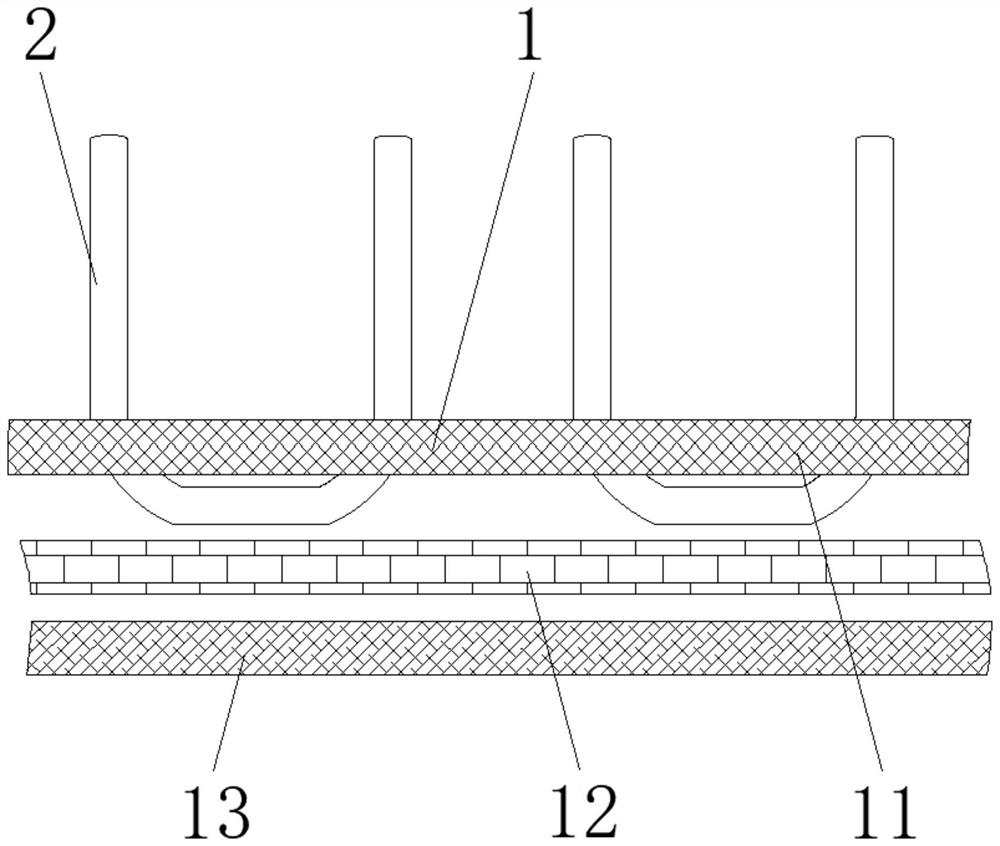

Image

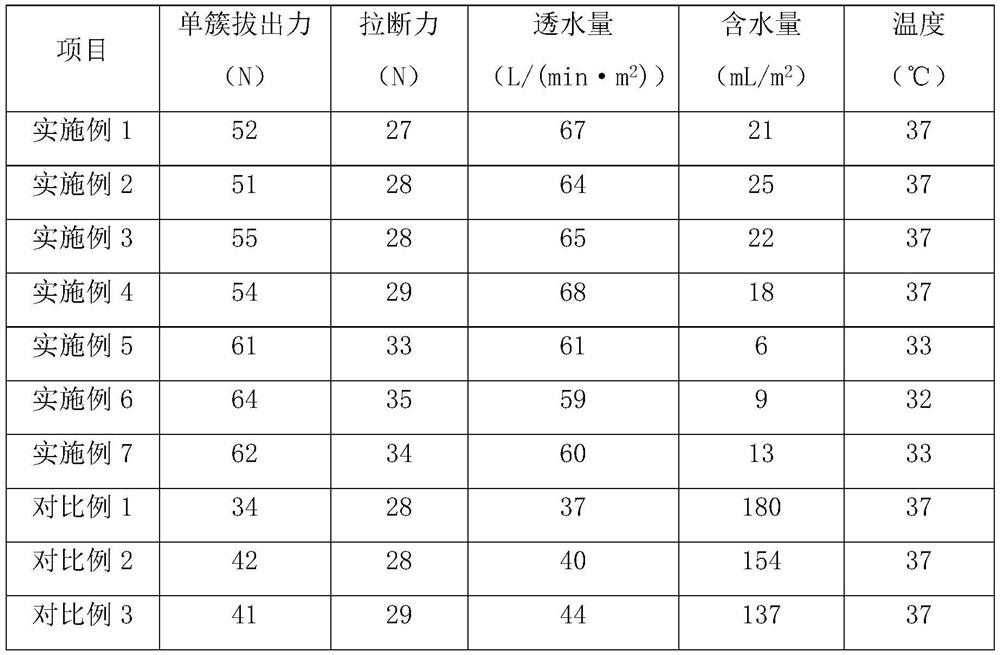

Examples

Embodiment 1

[0038] (1) Preparation of artificial grass fiber:

[0039] Take 90 parts of polyethylene, 4 parts of color masterbatch, 4 parts of light-stabilized masterbatch, 1 part of fluorine-containing additives, and 1 part of smooth masterbatch, mix them, and then extrude through a single-screw at 215 ° C. After cooling and setting, drawing and setting , After shrinkage and shaping, winding and twisting, the artificial grass fiber is obtained, and the weight of the artificial grass fiber is 12000 / 6F;

[0040] (2) Preparation of artificial turf:

[0041] Take one layer of 121g single-layer PP woven fabric as the base fabric A, use a tufting machine to weave the artificial grass fibers into the base fabric A, the knitting density is 5 / 8inch, and the needle distance is 180 needles / m, and the gray fabric C is obtained;

[0042] Use a single-screw extruder to melt-blown the raw material of the omentum cloth into a net, and lay it evenly on the bottom of the gray cloth. The temperature of th...

Embodiment 2

[0045] (1) Preparation of artificial grass fiber:

[0046] Take 90 parts of polyethylene, 4 parts of color masterbatch, 4 parts of light-stabilized masterbatch, 1 part of fluorine-containing additives, and 1 part of smooth masterbatch, mix them, and then extrude through a single-screw at 215 ° C. After cooling and setting, drawing and setting , After shrinkage and shaping, winding and twisting, the artificial grass fiber is obtained, and the weight of the artificial grass fiber is 12000 / 6F;

[0047] (2) Preparation of artificial turf:

[0048] Take a layer of 121g single-layer PP woven fabric and a layer of 60g grid cloth as the base fabric A, and use a tufting machine to weave the artificial grass fibers into the base fabric A, the knitting density is 5 / 8inch, and the stitch distance is 180 stitches / m. Gray cloth C is obtained;

[0049] Use a single-screw extruder to melt-blown the raw material of the omentum cloth into a net, and lay it evenly on the bottom of the gray clo...

Embodiment 3

[0052] (1) Preparation of artificial grass fiber:

[0053] Take 90 parts of polyethylene, 4 parts of color masterbatch, 4 parts of light-stabilized masterbatch, 1 part of fluorine-containing additives, and 1 part of smooth masterbatch, mix them, and then extrude through a single-screw at 215 ° C. After cooling and setting, drawing and setting , After shrinkage and shaping, winding and twisting, the artificial grass fiber is obtained, and the weight of the artificial grass fiber is 8000 / 6F;

[0054] (2) Preparation of artificial turf:

[0055] Take two layers of 121g single-layer PP woven fabric as the base fabric A, and use a tufting machine to weave artificial grass fibers into the base fabric A, with a knitting density of 3 / 8 inch and a needle pitch of 150 stitches / m to obtain gray fabric C;

[0056] Use a single-screw extruder to melt-blown the raw material of the omentum cloth into a net, and lay it evenly on the bottom of the gray cloth. The temperature of the single-scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com