A rotary arm type lifting device used in a substation

A hoisting device and arm-type technology, applied in cranes, transportation and packaging, engine lubrication, etc., can solve problems such as inconvenient transportation and handling, poor stability and reliability, and long poles, so as to improve work stability and The effect of service life, increased load bearing area, and reduced bending degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

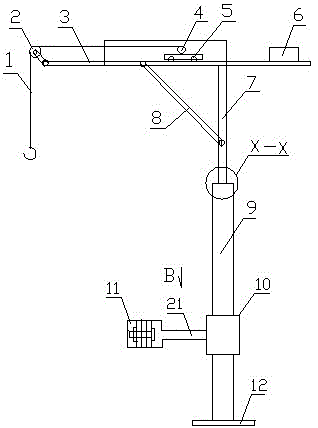

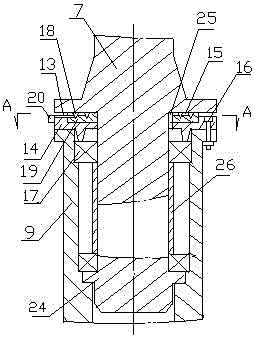

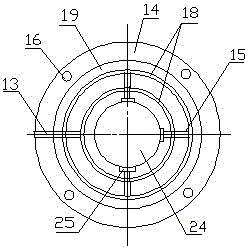

[0012] in figure 1 , figure 2 , image 3 with Figure 4 Wherein, the boom-type lifting device used in the substation includes a rotating column 7, a column 9, a beam 3, a drum 4, and a mobile trolley 5. The beam is fixed on the rotating column, and one end of the beam is provided with a runner 2 (pulley) , The other end is provided with a counterweight 6, the mobile trolley is set on the cross beam 3, the reel 4 is set on the mobile trolley 5, a diagonal brace 8 is set between the cross beam and the rotating column, and the rope 1 on the reel is Hook and go around the runner, the lower end of the column is provided with a rotating sleeve 10, the rotating sleeve is connected to the movable hoop 11 through the connecting plate 21, the column and the movable hoop are fixed to the fixing member 23 (such as The lower end of the column is provided with a base 12 on the electric pole, cement column). The movable hoop can fix the column when clamped. The connecting shaft 24 at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com