Bacteriostatic constant-pressure water purifier for providing mineral water by using water purifying agent

A water purifying agent and mineral water technology, applied in water/sewage treatment, multi-stage water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problem of poor control of time, failure to replace in time, and excessive total number of bacterial colonies and other problems, to achieve the effect of practical operation, reduced replacement times, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

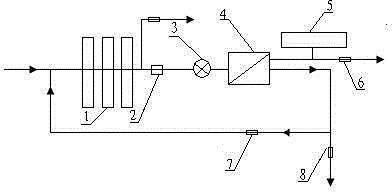

Image

Examples

Embodiment 1

[0016] In the activated carbon filter element for water purification in this embodiment, the main material of the filter element is activated carbon, wherein a water purifying agent is added to the activated carbon, and the formula weight ratio of the water purifying agent is as follows: KDF, 20 parts; medical stone powder, 20 parts; Lin powder, 20 parts; negative ion powder, 20 parts. Among them, the particle size of medical stone powder, tourmaline powder and negative ion powder is equal to 500 mesh.

[0017] The production process is as follows:

[0018] The first step is to mix the raw carbon of activated carbon with the superfine powder of water purifier in the formula, then add ceramic powder, pore opening agent and clay and mix evenly;

[0019] In the second step, the mixture in the above-mentioned first step is fired into irregularly shaped granular carbon, and the particle diameter is between 1-3mm;

[0020] In the third step, the granular carbon in the second step ...

Embodiment 2

[0024] In the activated carbon filter element for water purification in this embodiment, the main material of the filter element is activated carbon, wherein a water purifying agent is added to the activated carbon, and the formula weight ratio of the water purifying agent is as follows: KDF, 25 parts; medical stone powder, 25 parts; Lin powder, 25 parts; negative ion powder, 25 parts. Among them, the particle size of medical stone powder, tourmaline powder and negative ion powder is equal to 300 mesh.

[0025] The production process is as follows:

[0026] The first step is to mix the raw carbon of activated carbon with the superfine powder of water purifier in the formula, then add ceramic powder, pore opening agent and clay and mix evenly;

[0027] In the second step, the mixture in the above-mentioned first step is fired into irregularly shaped granular carbon, and the particle diameter is between 1-3mm;

[0028] In the third step, the granular carbon in the second step ...

Embodiment 3

[0032] In the activated carbon filter element for water purification in this embodiment, the main material of the filter element is activated carbon, wherein a water purifying agent is added to the activated carbon, and the formula weight ratio of the water purifying agent is as follows: KDF, 30 parts; medical stone powder, 30 parts; Lin powder, 30 parts; negative ion powder, 30 parts. Among them, the particle size of medical stone powder, tourmaline powder and negative ion powder is equal to 100 mesh.

[0033] The production process is as follows:

[0034] The production process is as follows:

[0035] The first step is to mix the raw carbon of activated carbon with the superfine powder of water purifier in the formula, then add ceramic powder, pore opening agent and clay and mix evenly;

[0036] In the second step, the mixture in the above-mentioned first step is fired into irregularly shaped granular carbon, and the particle diameter is between 1-3mm;

[0037] In the third...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com