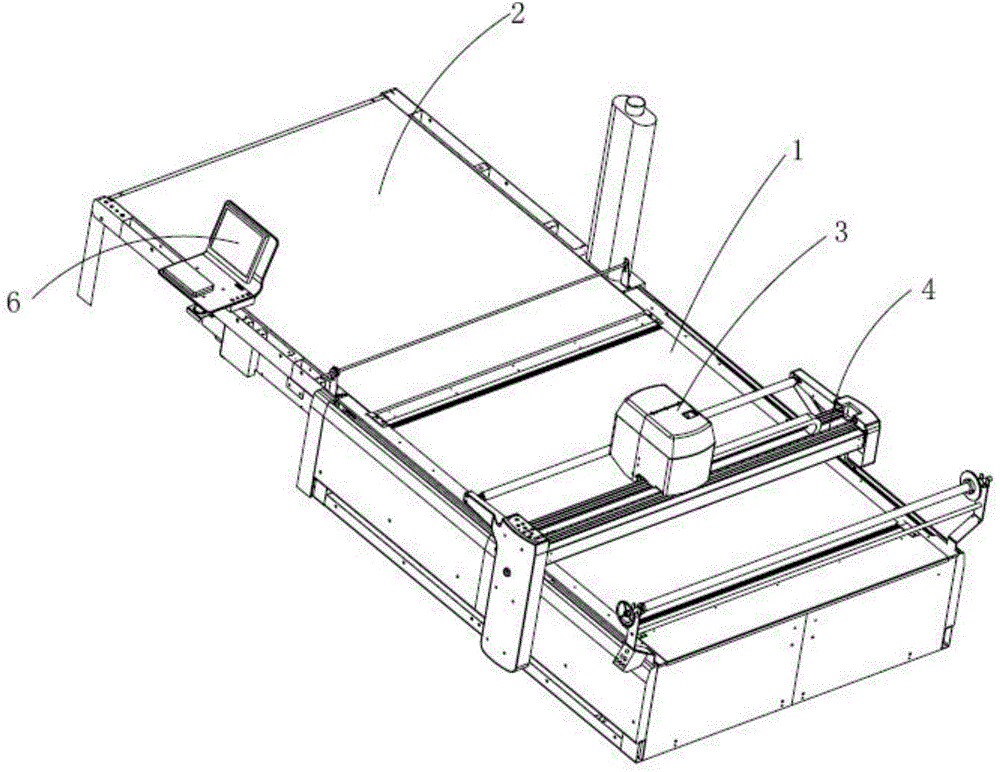

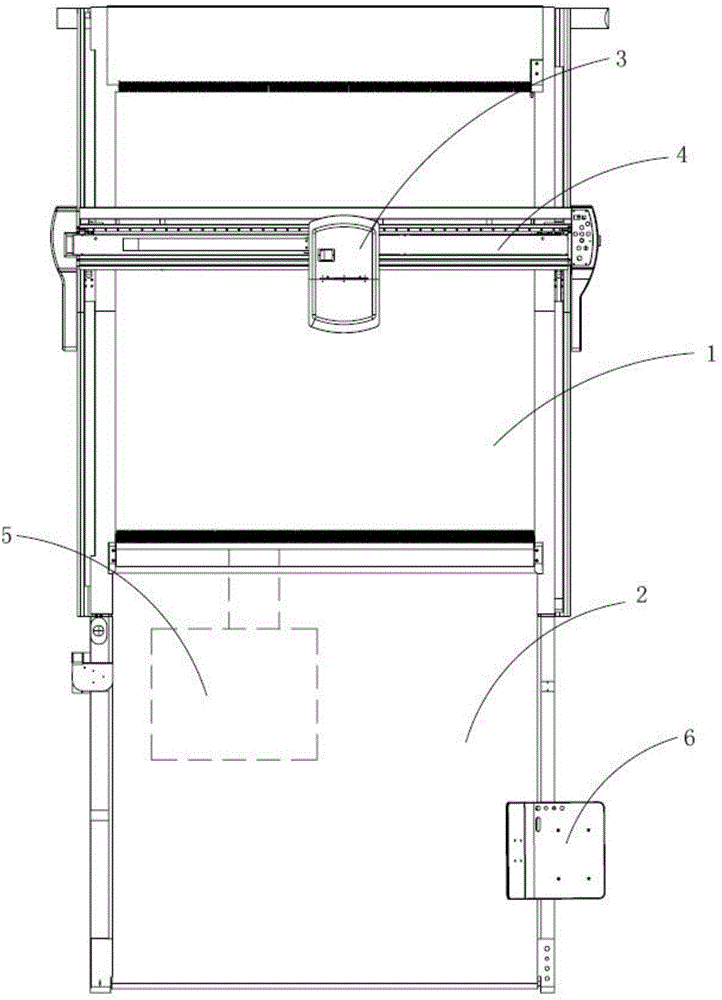

Large-width numerical control cutting machine

A cutting machine and wide-width technology, which is applied in the field of large-width CNC cutting machines, can solve the problems of increasing the risk of cutting materials to be cut, affecting the reliability of CNC cutting machines, and reducing cutting efficiency, so as to avoid rework The effect of reprocessing, reducing the risk of cutting damage, and improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

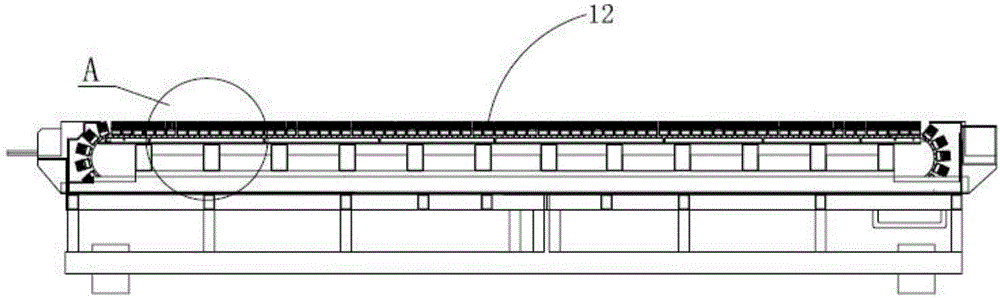

[0028] Please also refer to Figure 3 ~ Figure 7 As shown, the bristle brick 11 is fixed on the bristle tube 13, and the bristle tube 13 is in the shape of a strip, and the bristle tube 13 is supported on the large-width CNC cutting machine along the width direction. On the height-adjustable supports 14 at the two ends of the width direction of the CNC cutting machine.

[0029] The height-adjustable support body 14 is in the shape of a strip as a whole, including two end pieces 140, a plurality of bearing assemblies 141, two vertical plates 142, a plurality of fixing pieces 143 and two fixing plates 144, and the bearing assembly 141 includes Bearing 1411 and bearing shaft 1412, the number of corresponding bearing shafts 1412 on the described vertical plate 142 is provided with a corresponding number of waist-shaped holes 1420, and the described bearing shaft 1411 passes through the waist-shaped holes 1420 on the described vertical plate 142 and passes through the The fixed pa...

Embodiment 2

[0033] see Figure 9 As shown, the bristle tube 13 in the cutting area is fully supported on the support body, and the bristle bricks 11 fixed in each bristle tube 13 in the cutting area 1 are of the same size. The size is set to control the entire cutting table 12 to be arched along the length direction of the large-width CNC cutting machine. The cut surface of the bristles 111 on the surface of the bristle brick 11 is arc-shaped, and is center-symmetrically arranged in the cutting area 1 . When the width of the CNC cutting machine is 2.6-3.2 meters, the height of the arch h is 0.5-2cm. The structures and working principles of other parts are basically the same as those in Embodiment 1, and will not be repeated here.

[0034] The large-width numerical control cutting machine of the present invention arranges the cutting table in an arched shape along the length direction of the large-width numerical control cutting machine, so that when the cutting width of the numerical co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com