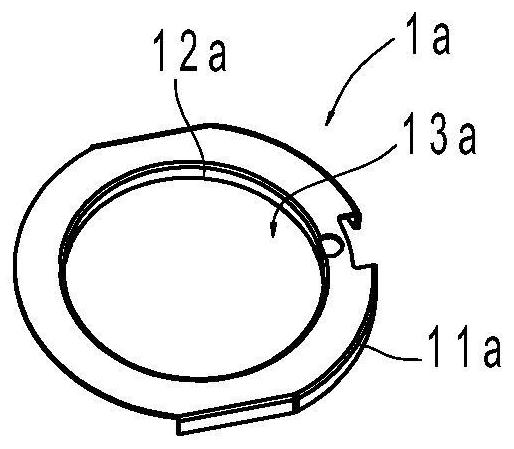

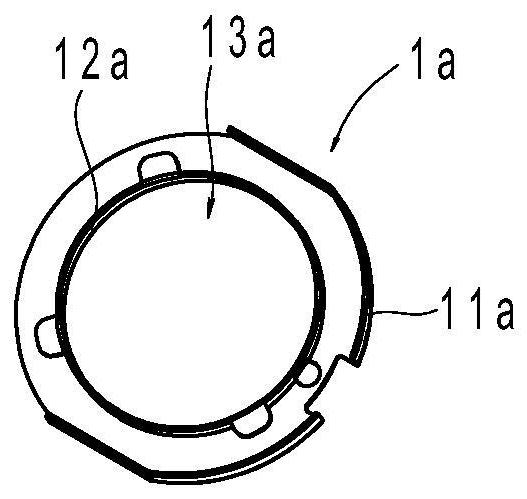

Fin ring bearing mechanism and punch forming device with same

A fin ring and fin technology, applied in the field of stamping and forming devices, can solve the problems of high defective rate and scrap rate, reduced finger flexibility and sensitivity, low efficiency, etc. Reduced risk of cuts and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

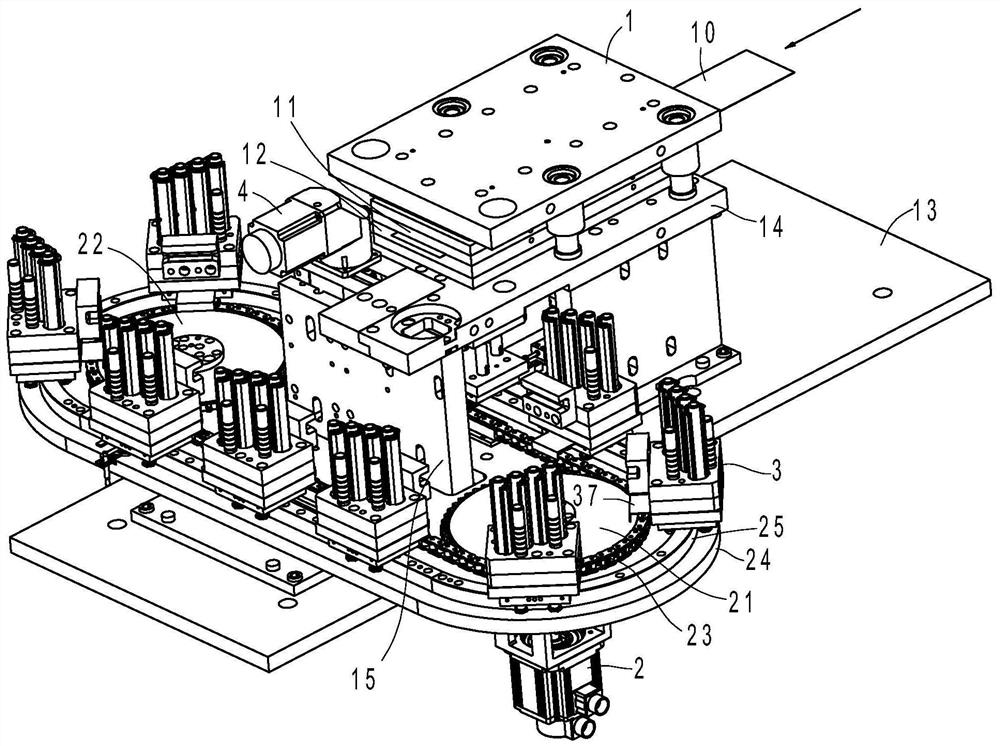

Embodiment 1

[0038] Example 1, such as image 3 with Figure 4 As shown, the fin ring stamping and forming device in this embodiment includes a body 1, a stamping head 112, a stamping die and a fin ring receiving mechanism, combined with Image 6 with Figure 7 As shown, the stamping head 112 is arranged on the machine body 1 so that it can move up and down. There is a discharge port 122 in the stamping die. A die cutting knife 121 is provided on the discharge port 122. The inner cavity of the die cutting knife 121 is adapted to the fin ring. . The body 1 is provided with a waste material punch 111 and a forming punch 114, and the stamping die includes an upper template 11, a lower template 12, an upper shaping assembly 124 arranged on the upper template 11, and a lower shaping assembly 113 arranged on the lower template 12. The template 12 has a discharge hole 123 for waste discharge and a discharge port for the fin ring to drop. The discharge hole 123 is located directly below the was...

Embodiment 2

[0045] Example 2, such as Figure 9 with Figure 10 As shown, the lifting mechanism 4 in this embodiment includes a vertically arranged lifting cylinder 45 and a connecting plate 43 located at the bottom end of the lifting cylinder 45. The connecting plate 43 is detachably connected with the receiving plate 32. The lifting cylinder in this embodiment 45 is located on the mounting plate. Refer to Example 1 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com