Rectification energy dissipation method for inverse step stilling basin and stilling basin

A stilling pool and anti-step technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of violent tumbling of the water flow at the top of the tail sill, poor connection of downstream water levels, and increased aeration, so as to reduce downstream erosion, Dissipating flow velocity distribution and the effect of adjusting the flow velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

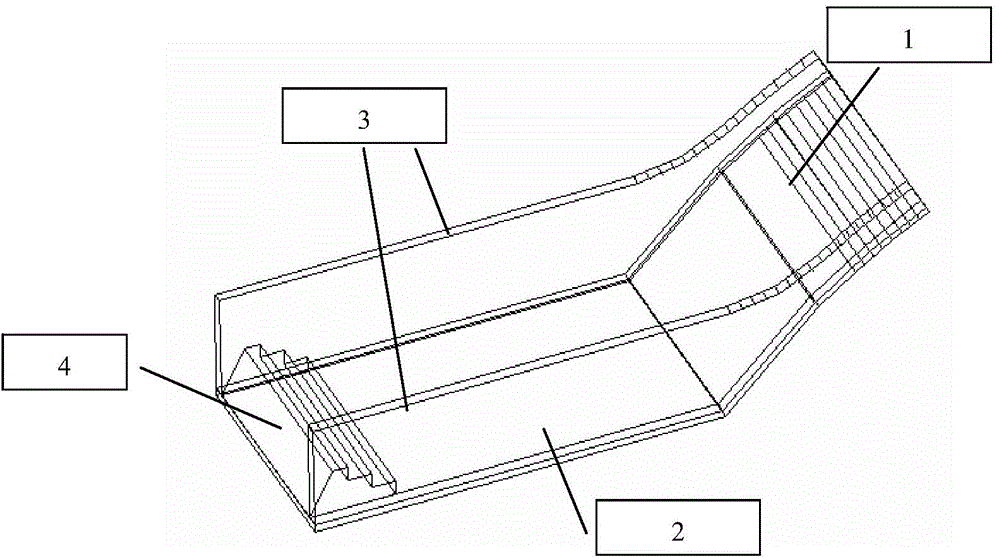

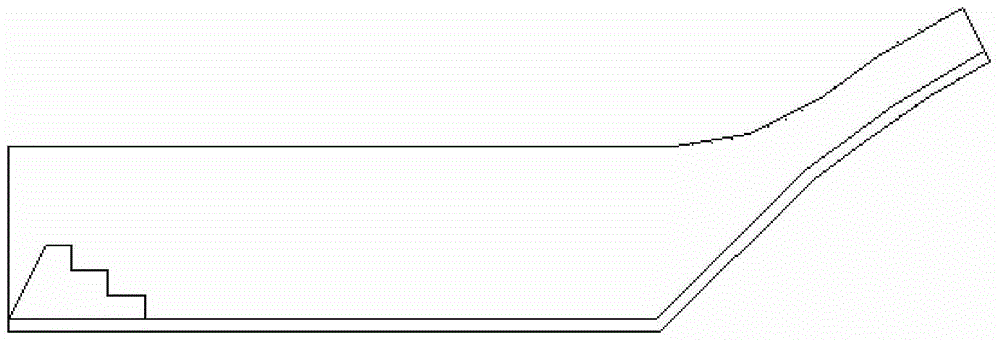

[0019] Such as figure 1 , figure 2 As shown, the reverse step stilling pool is composed of the front sill 1, the bottom floor 2, the side walls 3 on both sides and the end sill 4. The elevation of the steps increases step by step along the direction of the water flow, and the incoming flow collides with the steps of the tail sill 4 in layers, so that the water flow in front of the pool is fully collided, mixed, and turbulent, reducing the flow rate of the pool, increasing the water level of the tail water, and increasing the hydraulic jump. The conjugate water depth increases the energy dissipation efficiency in the pool.

[0020] The side walls 3 on both sides are plane, and are symmetrically distributed with respect to the central axis of the stilling pool to form a symmetrical equal-width stilling pool, and the tail sill 4 is composed of symmetrical steps equal to the width of the stilling pool.

[0021] The order of the tail sill 4 is 3, and the height of a single step ...

Embodiment 2

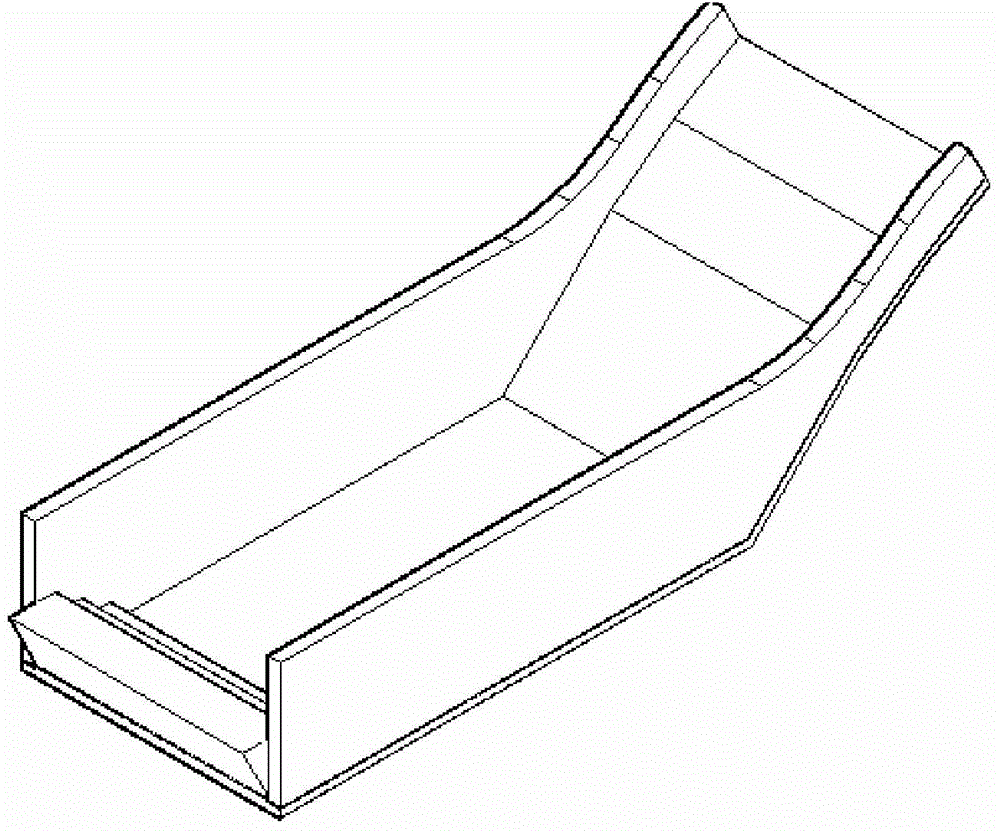

[0023] The reverse step stilling pool is composed of the front sill 1, the bottom floor 2, the side walls 3 on both sides and the end sill 4. The rear sill 4 is set as a continuous reverse step tail sill, and the steps of the continuous reverse step flow along the water The elevation in the direction increases step by step, and the incoming flow collides with the steps of the tail sill in layers, so that the water flow in front of the pool is fully collided, mixed, and turbulent, reducing the flow rate of the pool, increasing the water level of the tail water, and increasing the conjugate water depth of the hydraulic jump. Increase the efficiency of energy dissipation in the pool.

[0024] The side walls 3 on both sides are plane, and are symmetrically distributed with respect to the central axis of the stilling pool to form a symmetrical equal-width stilling pool, and the tail sill 4 is composed of symmetrical steps equal to the width of the stilling pool.

[0025] The order ...

Embodiment 3

[0027] The reverse step stilling pool is composed of the front sill 1, the bottom floor 2, the side walls 3 on both sides and the end sill 4. The rear sill 4 is set as a continuous reverse step tail sill, and the steps of the continuous reverse step flow along the water The elevation in the direction increases step by step, and the incoming flow collides with the steps of the tail sill in layers, so that the water flow in front of the pool is fully collided, mixed, and turbulent, reducing the flow rate of the pool, increasing the water level of the tail water, and increasing the conjugate water depth of the hydraulic jump. Increase the efficiency of energy dissipation in the pool.

[0028] The side walls 3 on both sides are plane, and are symmetrically distributed with respect to the central axis of the stilling pool to form a symmetrical equal-width stilling pool, and the tail sill 4 is composed of symmetrical steps equal to the width of the stilling pool.

[0029] The steps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com