Deformed inverse step rectifying energy dissipation method and stilling basin

A technology of reverse steps and stilling pools, which is applied in water conservancy projects, embankments, sea area engineering, etc., can solve the problems of difficult water flow energy dissipation, and the energy dissipation effect needs to be improved, so as to achieve energy dissipation flow velocity distribution, reduce downstream erosion, improve The effect of energy dissipation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

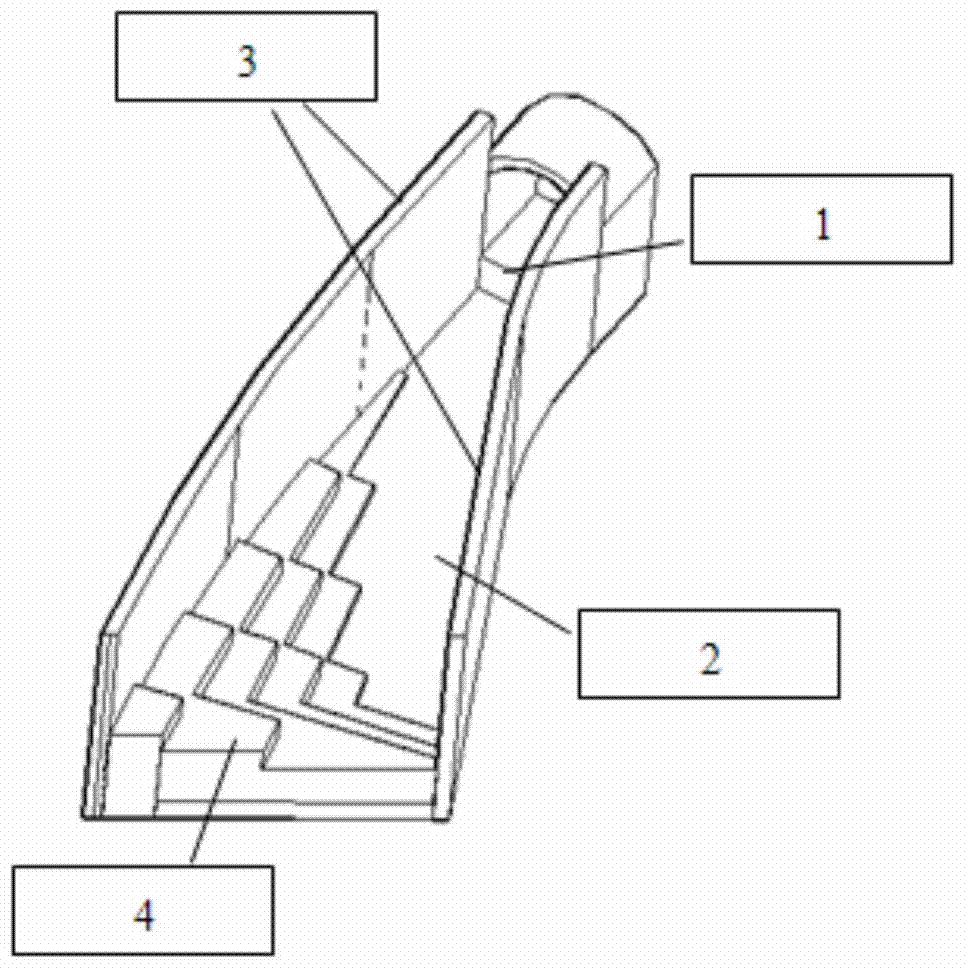

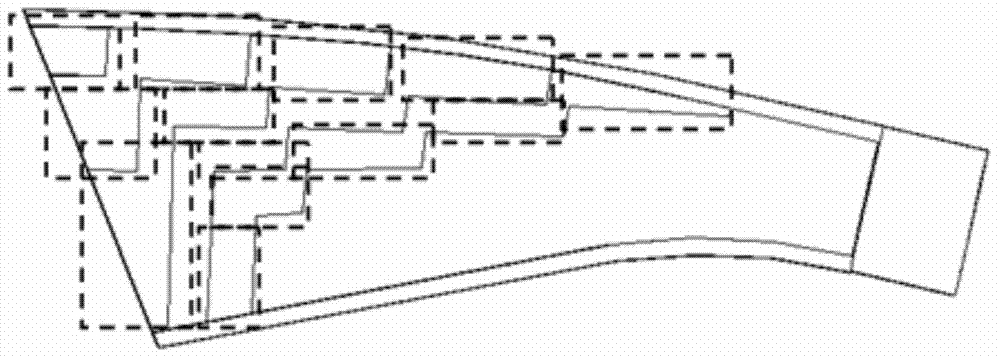

[0021] Such as figure 1 , figure 2 As shown, the special-shaped anti-step stilling pool is composed of a drop sill 1 at the front, a floor 2 at the bottom, side walls 3 on both sides and a tail sill 4 at the end. The sidewalls 3 on both sides are asymmetrically distributed and diffuse toward the river center in a curved surface. The curved surface diffusion can be in the form of plane, arc surface, elliptical arc surface and multiple curved surfaces, or any combination of various curved surfaces. Flow regime adjustments need to be decided. The tail sill 4 is set as a continuous reverse step tail sill, which is composed of steps whose width changes with the diffusion of the side wall of the stilling pool. The shape of the tail sill step is low at the entrance, high at the exit, low at the river center side, and high at the side near the bank slope, forming a horizontal and vertical three-dimensional special-shaped reverse step structure. The planar shape of the step unit in...

Embodiment 2

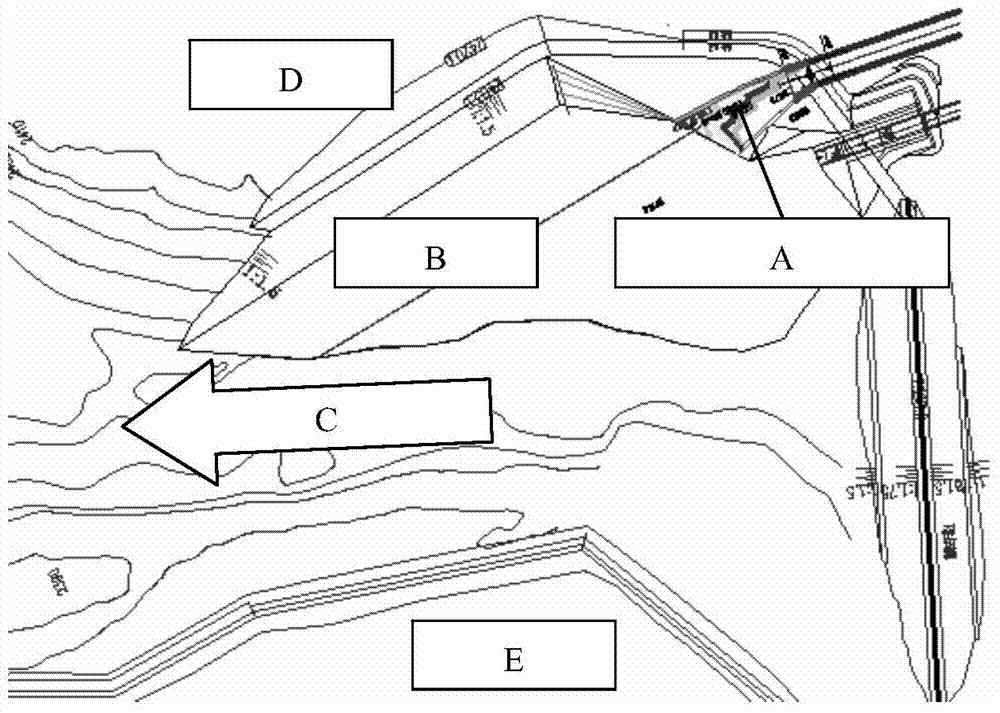

[0025] Taking the hydraulic model test of a certain project as an example, the single-width flow rate of the inlet water flow of the stilling pool is 399m 2 / s, Fr number is 1.48, the exit is close to the right bank slope D (the side of the stilling pool close to the right bank slope D is the near bank slope side, and the side close to the left bank slope E is the river center side), and the right bank slope D is The geology of the soil slope, the construction site on the bank, the geological condition of the exit bedrock is only about 80m, followed by the geological condition of deep overburden. If traditional methods such as tooth ridges, diversion piers, and twisted surfaces are used, it is difficult to smoothly return the mainstream to the center of the river, and the energy dissipation rate is extremely low. The downstream scour pit is more than 30m, and the protection cost is very high. The special-shaped anti-step stilling pool is used to form a complete and stable hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com