An Improved Installation Method of Flash Converting Furnace

An installation method and blowing furnace technology, which are applied in the processing of building materials, construction, building structure, etc., can solve the problems of large space occupation of scaffolding, complicated preparation work, and increase the cost of mechanical work, so as to reduce the construction cost of the project. , The effect of reducing the use of mechanical shifts and shortening the construction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

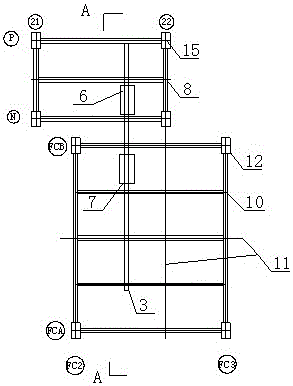

[0038] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0039] An improved flash converting furnace installation method is characterized in that it comprises the following steps:

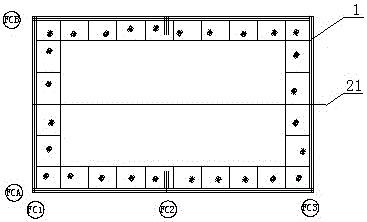

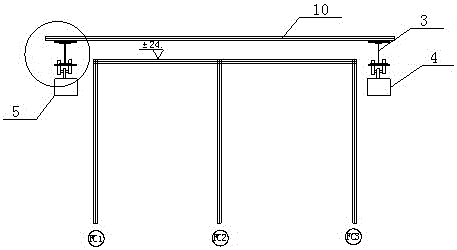

[0040] a. Set the temporary main lifting device for the furnace body components to be transported back to the furnace body

[0041] figure 1 The steel platform is used for furnace body installation. The steel platform used in this measure is the supporting steel platform for the official use of the furnace body. Before the installation of the furnace body, the first construction is re-measurement of the center line of the furnace bottom foundation, re-measurement of the foundation elevation, and installation of the bottom beam in place. The construction provides a stable and safe working platform, which is convenient for the construction personnel to install and install the skeleton columns of the furnace body and the side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com