Patents

Literature

47results about How to "Shorten the construction cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

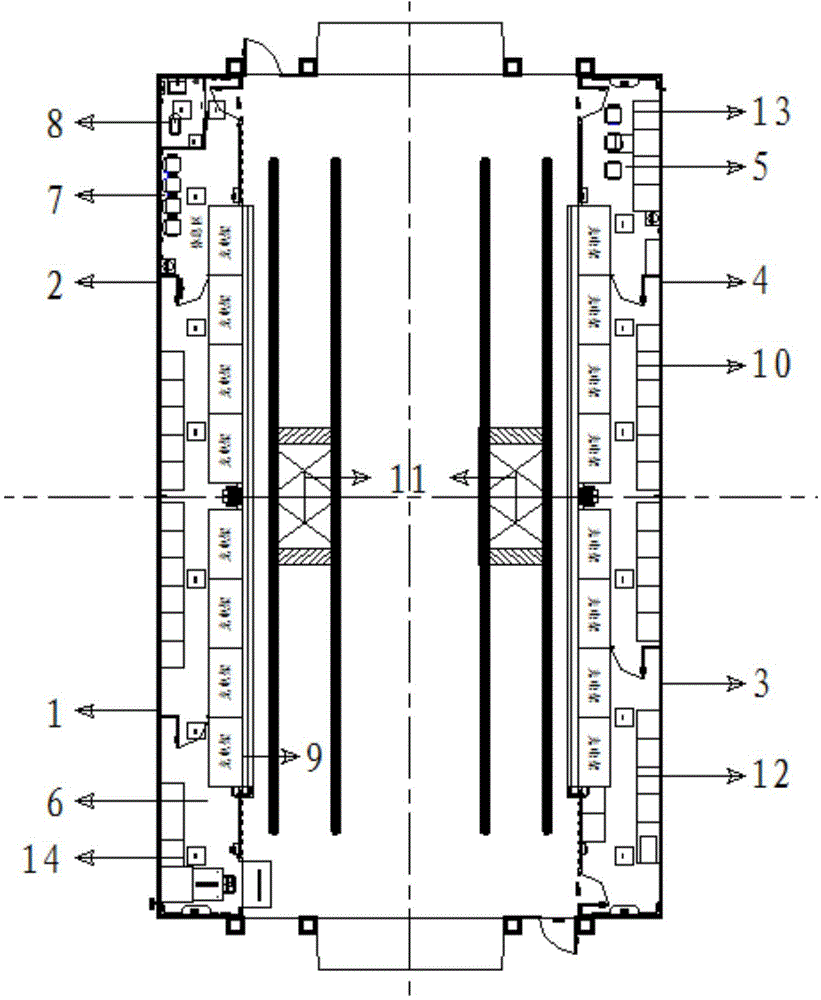

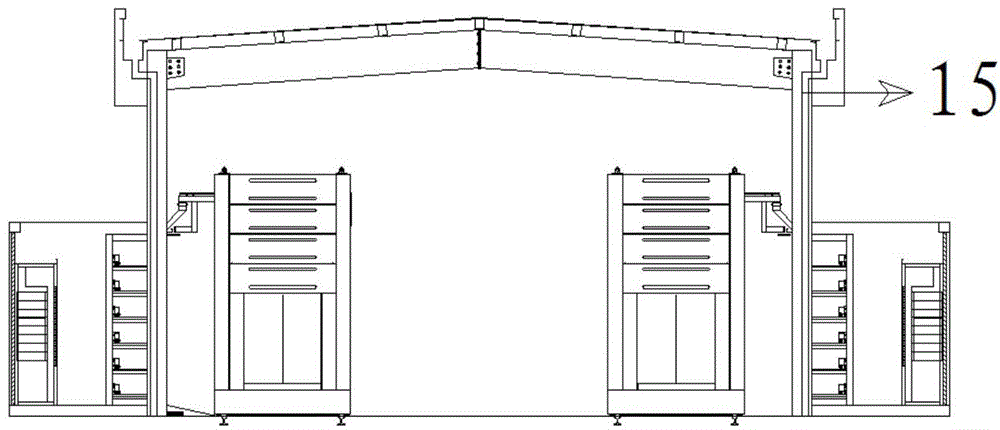

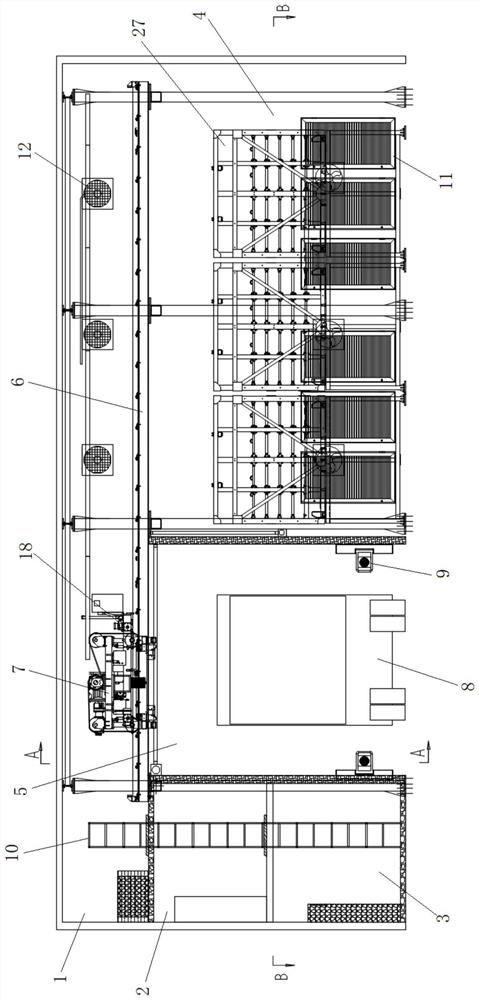

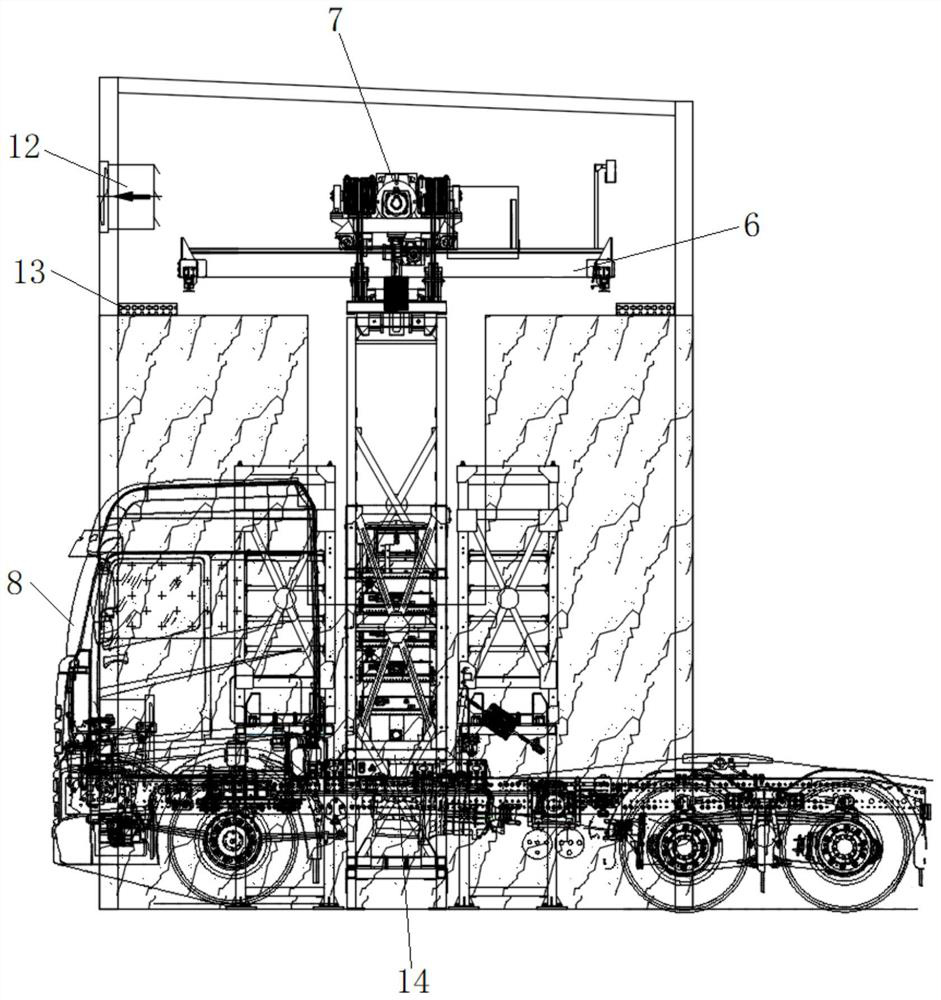

Prefabricated modularized intelligent electric car electric charging station

InactiveCN104908721AMove quicklyQuick assemblyElectric propulsion mountingVehicle servicing/repairingElectricityModularity

The invention relates to a prefabricated modularized intelligent electric car electric charging station which comprises a plurality of prefabricated box bodies, wherein a charging set cabinet, a charging rack, battery maintenance equipment, a monitoring cabinet and a monitoring room are orderly arranged in each box body according to function construction of the various parts; the charging racks in the box bodies are arranged on one side uniformly; the various prefabricated box bodies are arranged in two columns; an electric charging robot passage is arranged along the distributed direction of the box bodies in a stretching manner on one side of each column of box bodies where the charging racks are arranged; electric car passages are arranged on the other sides of the electric charging robot passages; the two electric car passages are adjacent; and the charging racks in the prefabricated box bodies are distributed on one side facing towards the electric charging robot passages. According to the prefabricated modularized intelligent electric car electric charging station, connection among electric cables among the equipment are completed in a manufacturing shop, and after the box bodies are transported to the site, only the following procedures are required to be done: the box bodies are fixed on the ground of the site and directly connected with a main incoming cable, and simple debugging is performed. The prefabricated modularized intelligent electric car electric charging station facilitates quick movement, assembly and combination; quick construction is realized; a station construction cycle is shortened; the cost is low; and the degree of automation is high.

Owner:XJ POWER CO LTD +2

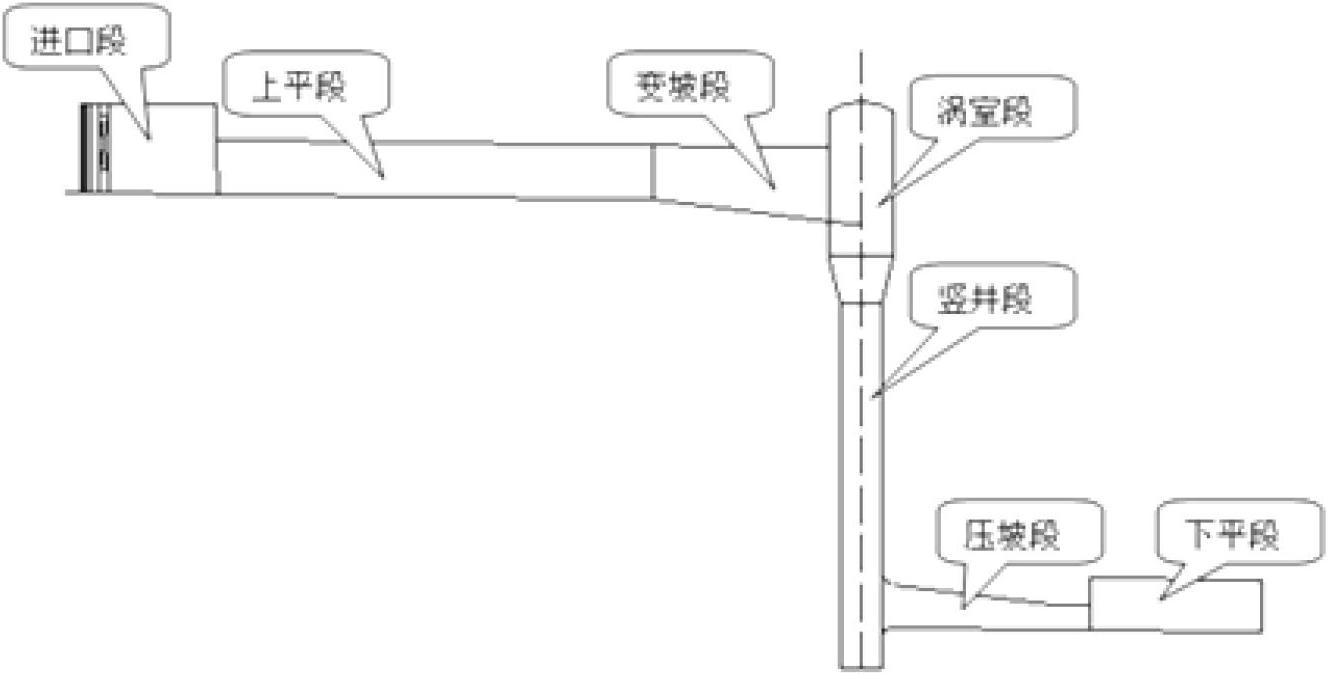

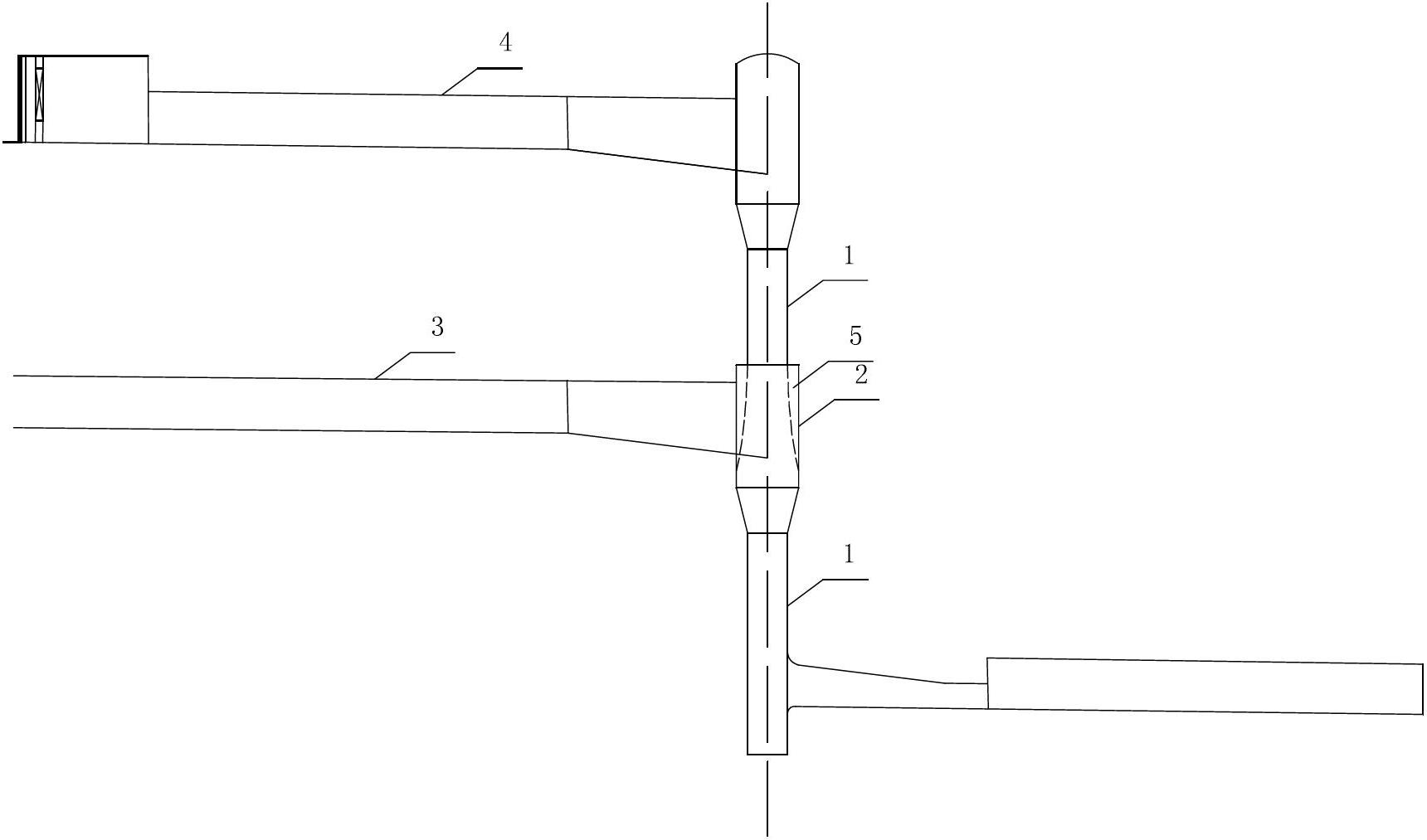

Swirling flow shaft with a plurality of swirling chambers

The invention discloses a swirling flow shaft with a plurality of swirling chambers. The swirling flow shaft is characterized in that at least one expanded swirling chamber is coaxially formed on the elevation of a shaft section of the swirling flow shaft, and each swirling chamber is connected with a corresponding drain tunnel; the diameter of a lower shaft with the swirling chambers is more than or equal to that of an upper shaft; and an inlet, which is connected with a corresponding swirling chamber, of a drain tunnel at a lower position is completely positioned in a sidewall cavity formed between a letdown water flow and the wall surface of the swirling chamber. The swirling flow shaft is ingenious in design; each swirling chamber can be connected with a drain tunnel running at a low level, and shares the same shaft, the same slope section, the same lower horizontal section and an outlet connected with a water flow in a downstream river channel, so that the construction cost of hydraulic engineering can be greatly lowered, the cycle of construction engineering can be shortened, and difficulty in the pivot distribution of the hydraulic engineering can be eliminated; and moreover, the swirling flow shaft is conveniently and flexibly used, and is high in applicability and particularly applied to hydraulic engineering with big changes in the water level of a reservoir area.

Owner:SICHUAN UNIV

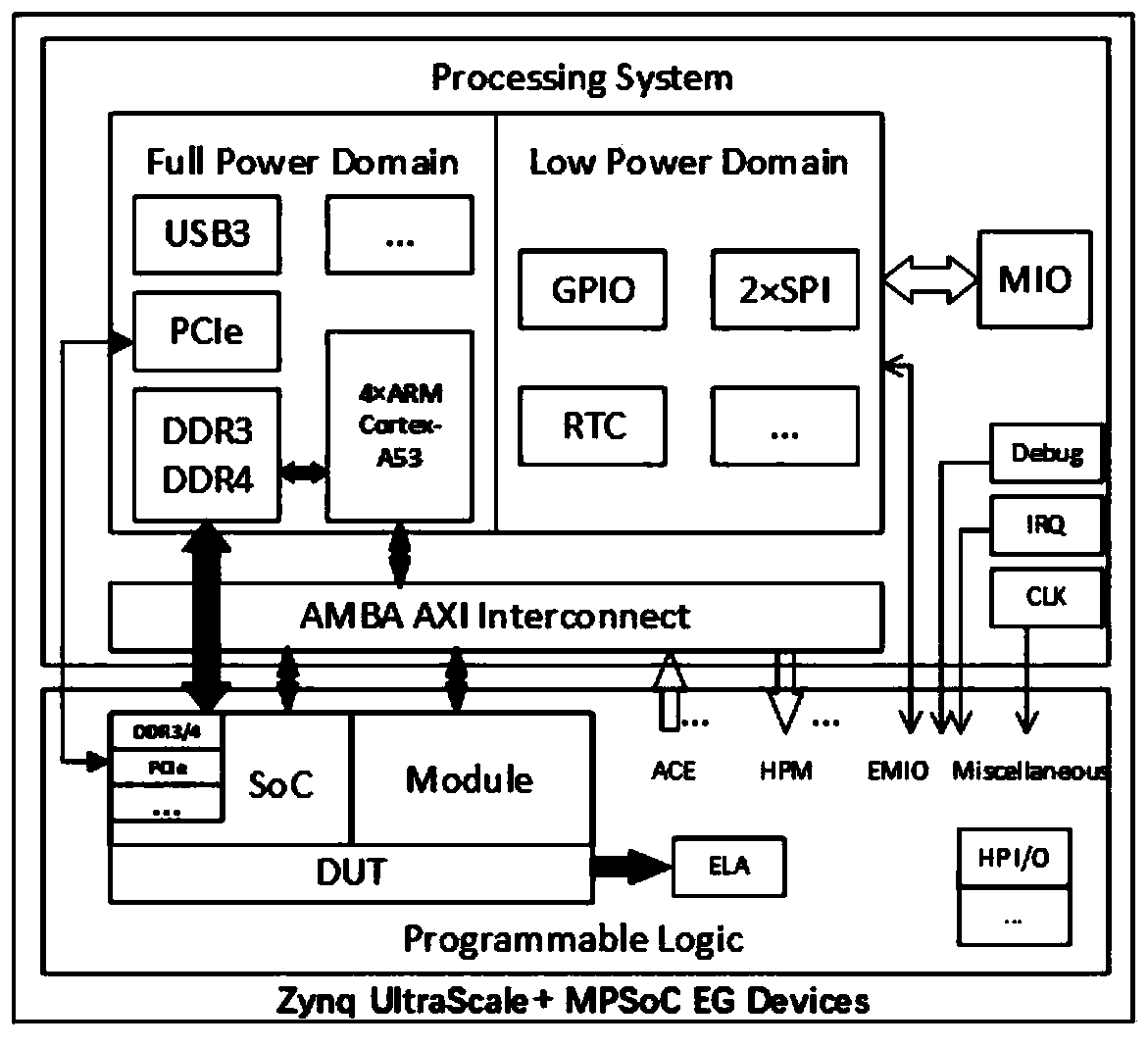

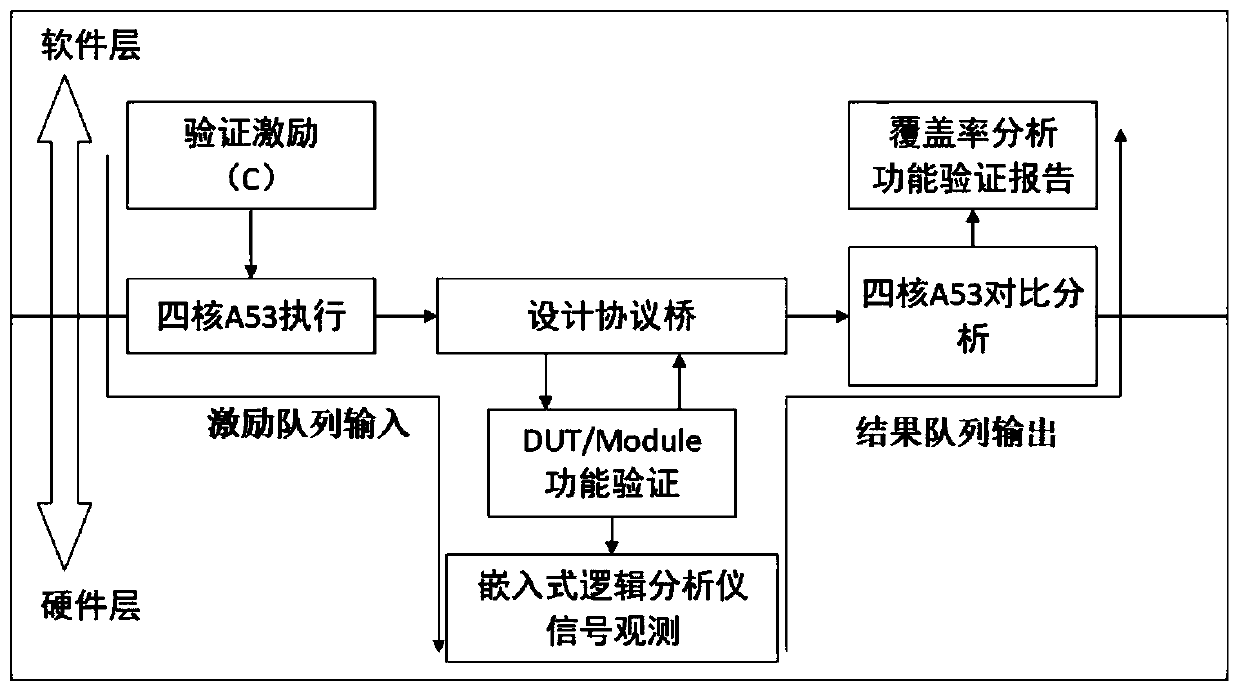

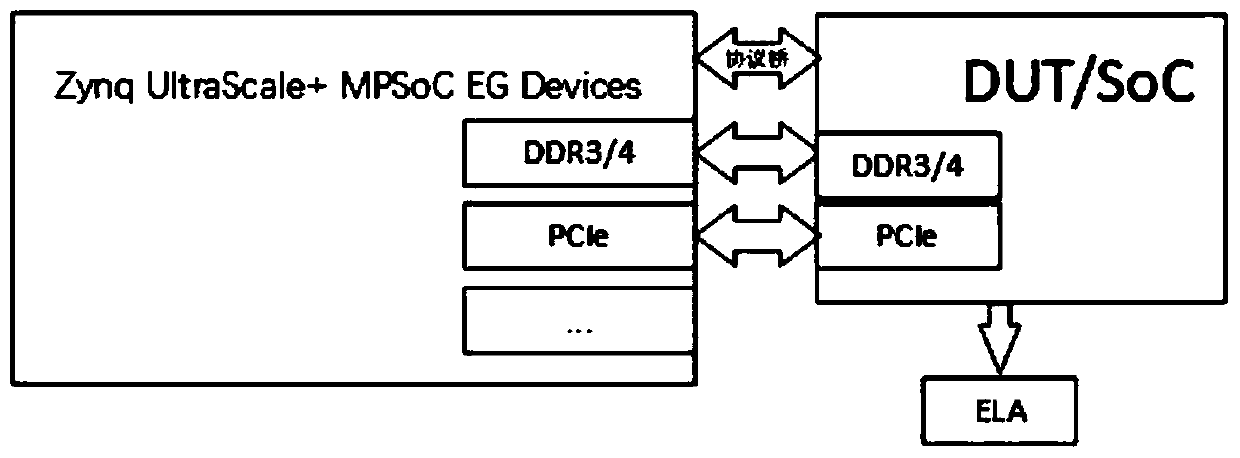

A verification system for improving digital circuit function verification efficiency

ActiveCN109885905AImprove portabilityShorten the construction cycleEnergy efficient computingSpecial data processing applicationsTest designComputer architecture

The invention provides a verification system for improving the digital circuit function verification efficiency. According to the verification system, the Zynq ULtraScales + MPSoC EG Devices are mainly adopted as a verification platform to carry out the corresponding verification operation, the verification operation can realize the effective separation of a software layer and a hardware layer inan execution process, while the separated hardware layer only needs to be compiled once, and even if the software layer is changed, the hardware layer does not need to be compiled again, so that the trouble that the hardware layer needs to be compiled when high-level language compiling excitation is changed each time due to the fact that the software layer and the hardware layer are not separatedis avoided. In addition, the verification system also designs and uses a protocol bridge and a verification stimulus with repeated availability, which improves the transportability of the verificationsystem. Under the condition that a protocol bridge with repeated availability or verification excitation can be directly utilized by a new tested design DUT, the establishment period of a new verification system is greatly shortened, and therefore the function verification period of the tested design DUT is shortened.

Owner:BEIJING CASUE TECH

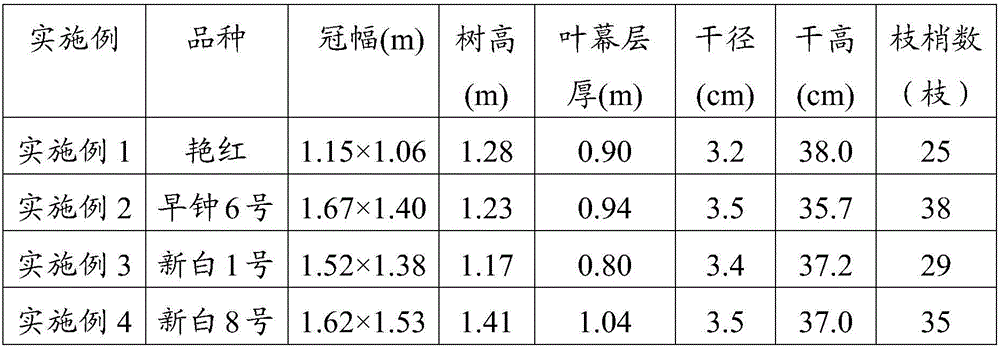

Cultivation method for putting planting loquat grafting shoots into production in advance

InactiveCN106538336AImprove colonization survival rateGrow neatlyGraftingCultivating equipmentsShootObserved Survival

The invention provides a cultivation method for putting planting loquat grafting shoots into production in advance. The cultivation method comprises the following steps of nursery stock cultivation, planting pit preparation, seedling planting and management after planting. The cultivation method is characterized in that a period from nursery stock sowing to outplanting is within one year and is shorter than a traditional seedling culture period by 1-2 years; and in addition, during nursery stock planting, roots, branches and leaves are not damaged, so that after nursery stock planting is carried out, a rejuvenation period is short, a planting survival rate is high and a way crops are growing is tidy. In addition, by use of the cultivation method disclosed by the invention, after planting is carried out, time for forming a crown which is put into production is shortened to two years, and is shortened by more than one year than the time for traditional plantation big seedlings to be put into production, i.e., by use of the cultivation method disclosed by the invention, the crown can be relatively quickly formed, and therefore, loquat saplings can be put into production in advance so as to shorten a garden building period, i.e., reduce garden building years and lower garden building cost.

Owner:POMOLOGY RES INST FUJIAN ACAD OF AGRI SCI

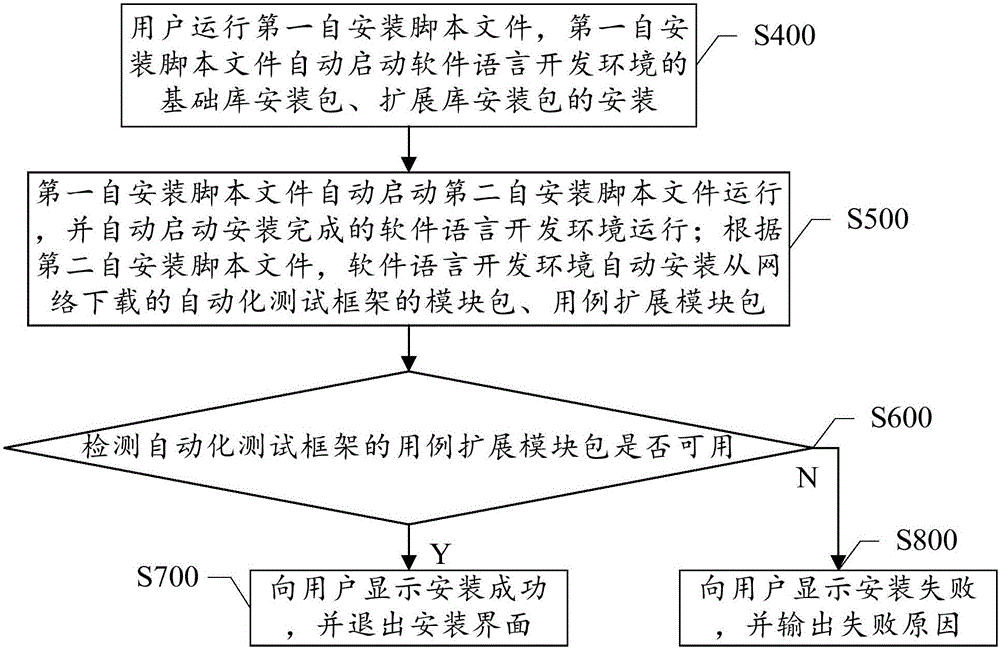

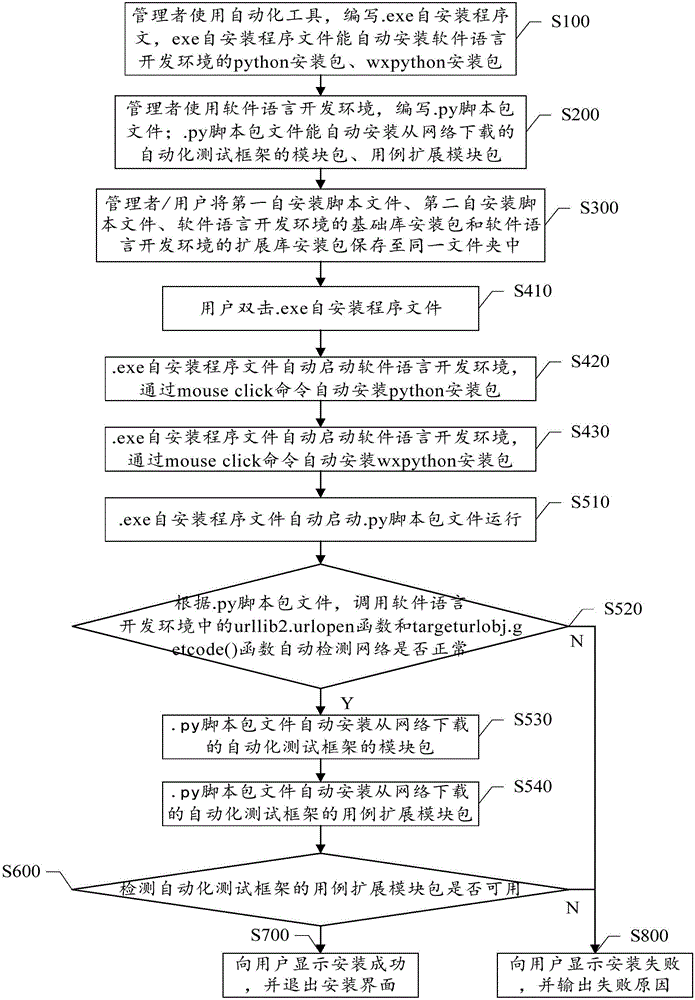

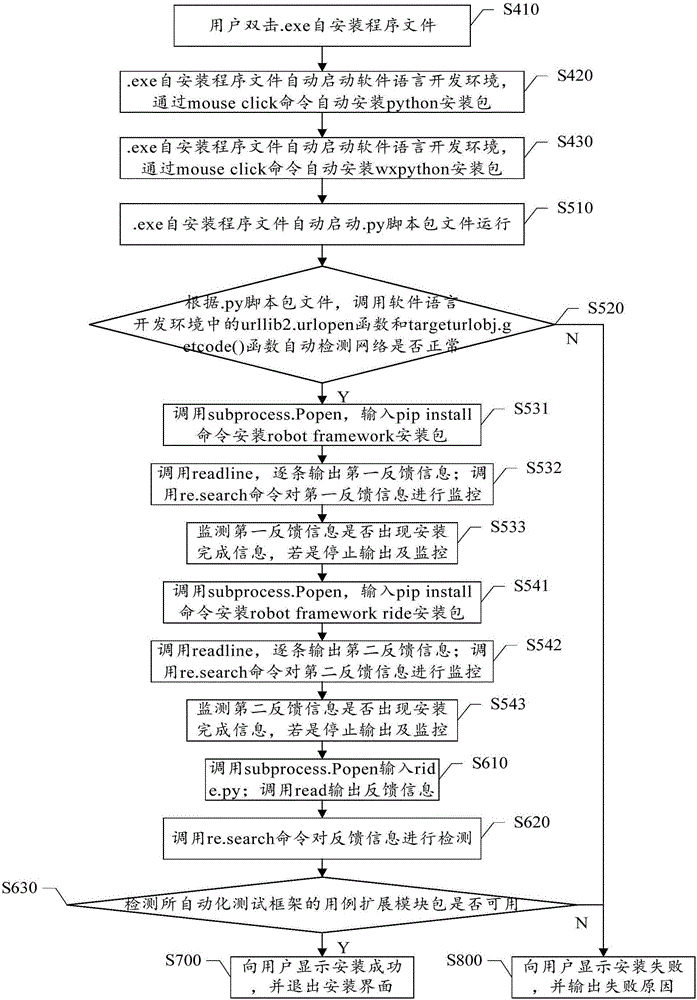

Self-installing method and system for automatic test frame

ActiveCN106598841AEasy to installShorten the construction cycleSoftware testing/debuggingProgram loading/initiatingTest frameSoftware language

The invention discloses a self-installing method and a self-installing system for an automatic test frame. The method comprises the following steps: S400, a user runs a first self-installation script file to automatically start the installation of a basic library installation package and an extension library installation package of a software language development environment; S500, the first self-installation script file automatically starts the running of a second self-installation script file, and self-starts the running of the installed software language development environment; the software language development environment automatically installs a module package and a use case extension module package of the automatic test frame downloaded from a network; and S600, whether the use case extension module package of the automatic test frame is available is detected, if yes, the step S700 is executed to show successful installation to the user and quit an installation interface; and otherwise, the step S800 is executed to show failed installation to the user and output a failure reason. According to the method and the system provided by the invention, installation of the automatic test frame is simplified, workload of testers is relieved, an automatic environment construction period is shortened, and test costs are reduced.

Owner:浙江安吉椅业科技有限公司

Antenna test system and test method

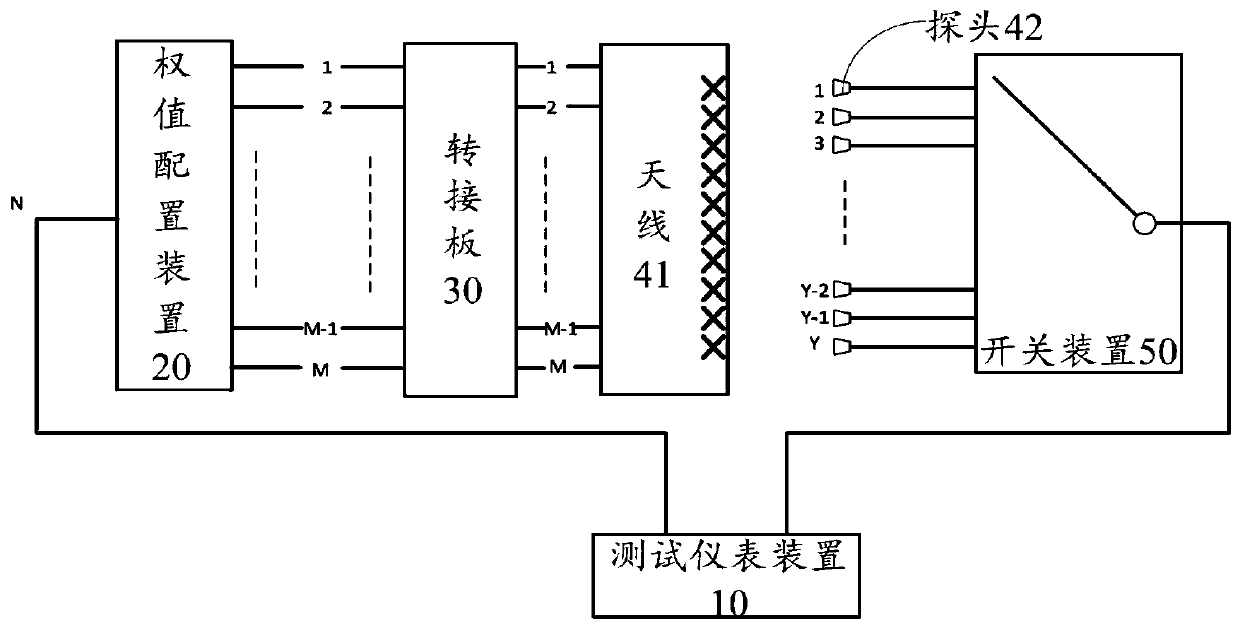

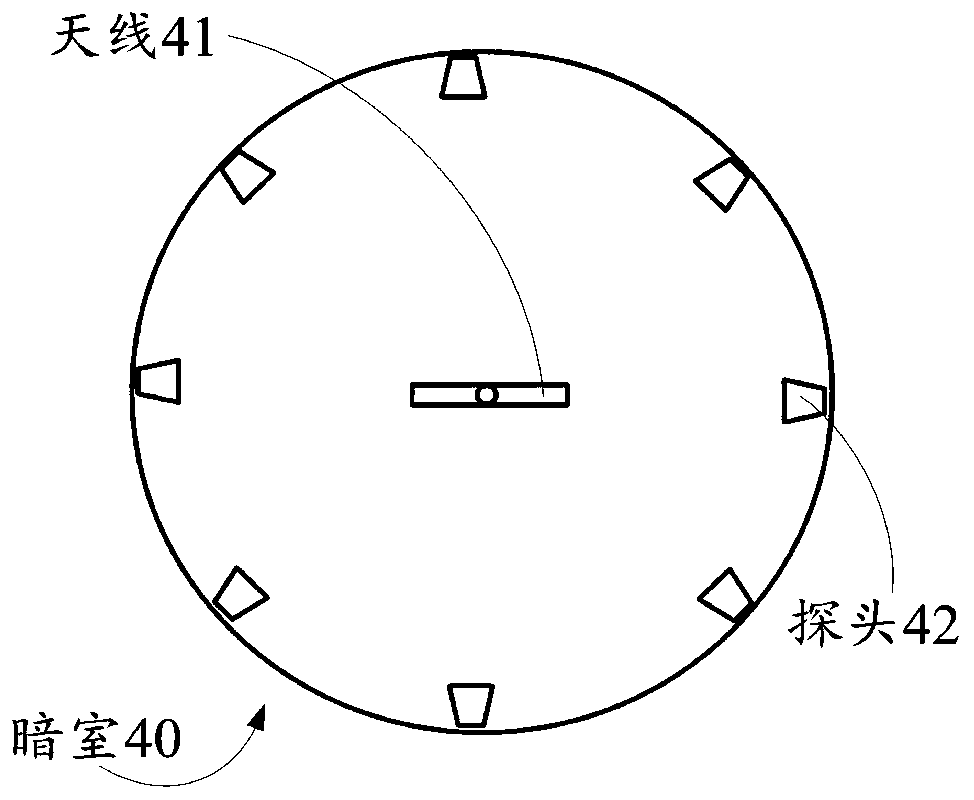

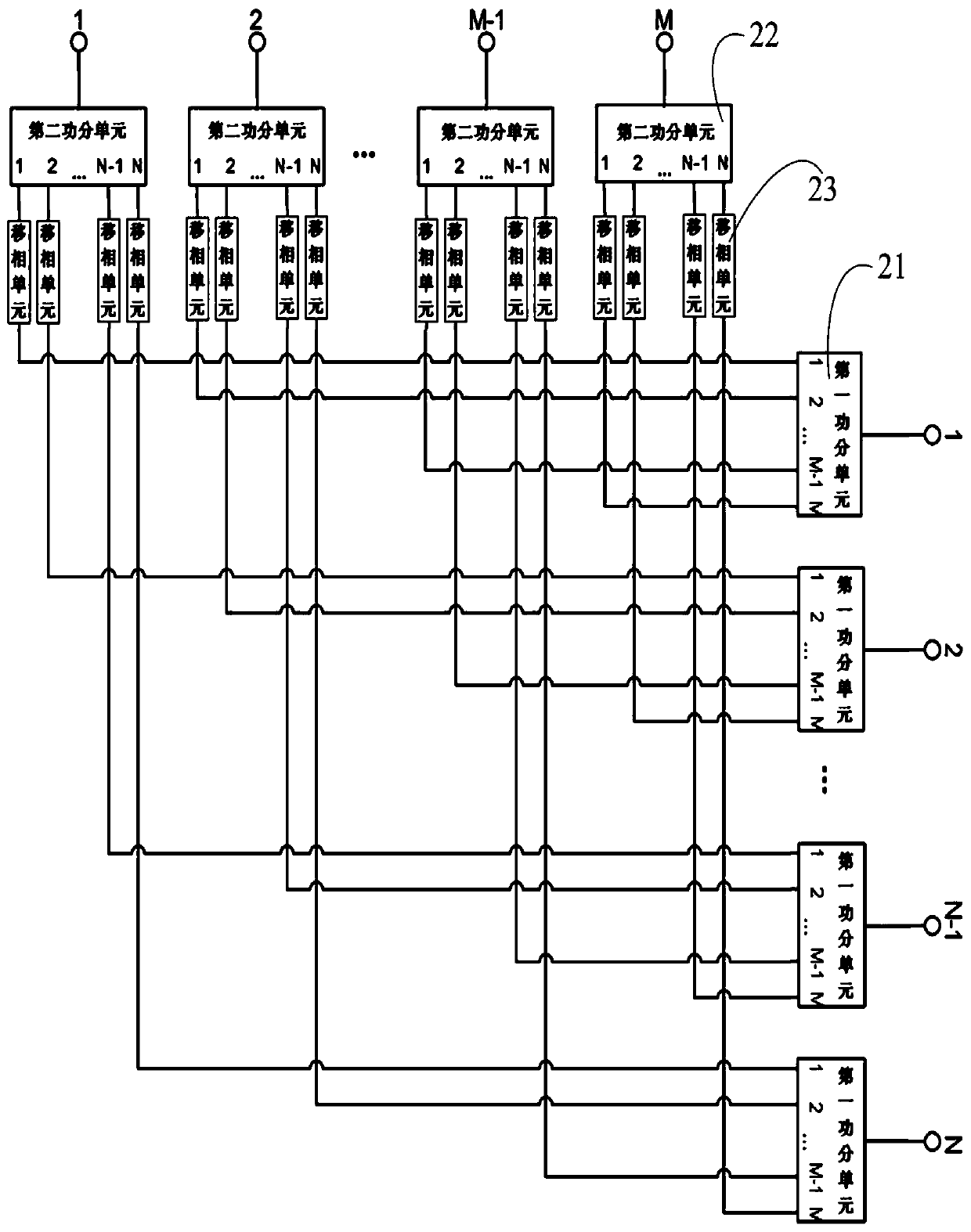

PendingCN111413553AImprove efficiencyImprove stabilityElectromagentic field characteristicsAntenna radiation diagramsBeam angleTester device

In order to solve the technical problems of low test efficiency, poor stability and incapability of freely changing a beam angle in an existing passive antenna test technology. The invention providesan antenna test system and a test method. The antenna test system comprises a test instrument device, a weight configuration device and a darkroom for placing an antenna, wherein the weight configuration device comprises a radio frequency matrix and a control module, the control module is connected with the radio frequency matrix, the test instrument device is connected with the radio frequency matrix, the radio frequency matrix is used for being connected with the antenna, the darkroom is provided with a probe, and the probe is connected with the test instrument device. According to the method disclosed in the invention, the beam angle of the third signal can be adjusted only by adjusting the weight parameter of the weight configuration device without changing the hardware structure in use, and therefore the efficiency and stability of antenna testing are improved; the weight parameter can be flexibly and freely adjusted, and therefore the beam angle of the third signal can be freelychanged.

Owner:NANJING JIEXI TECH

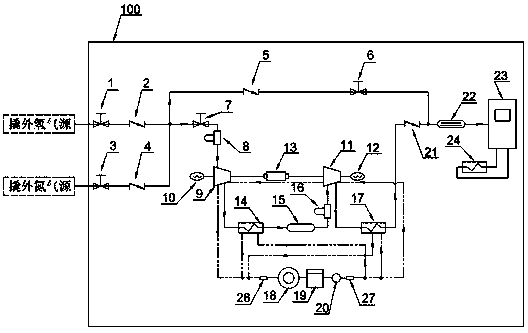

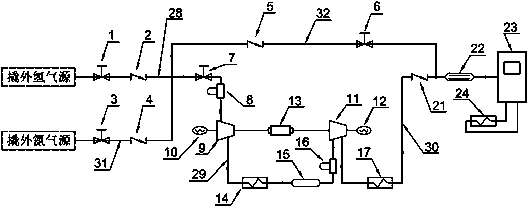

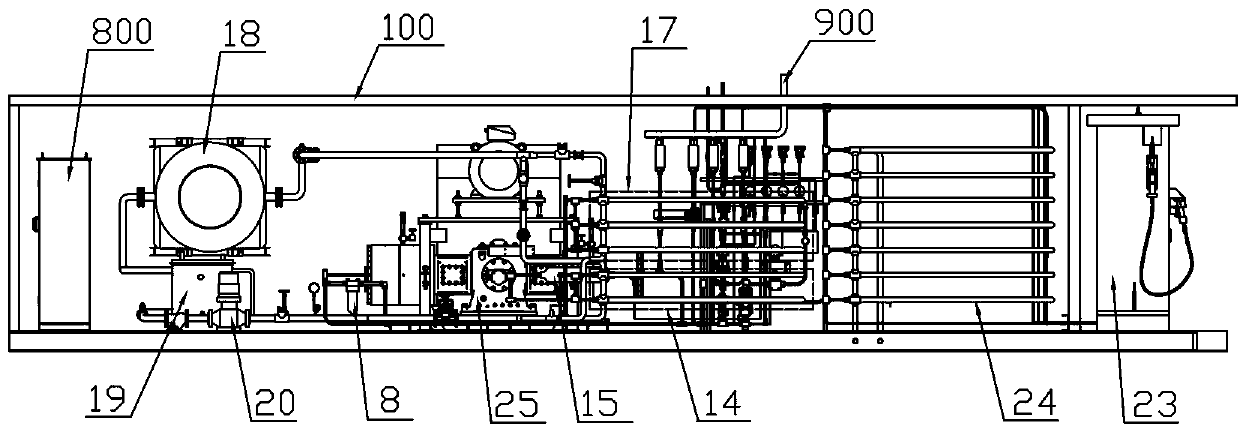

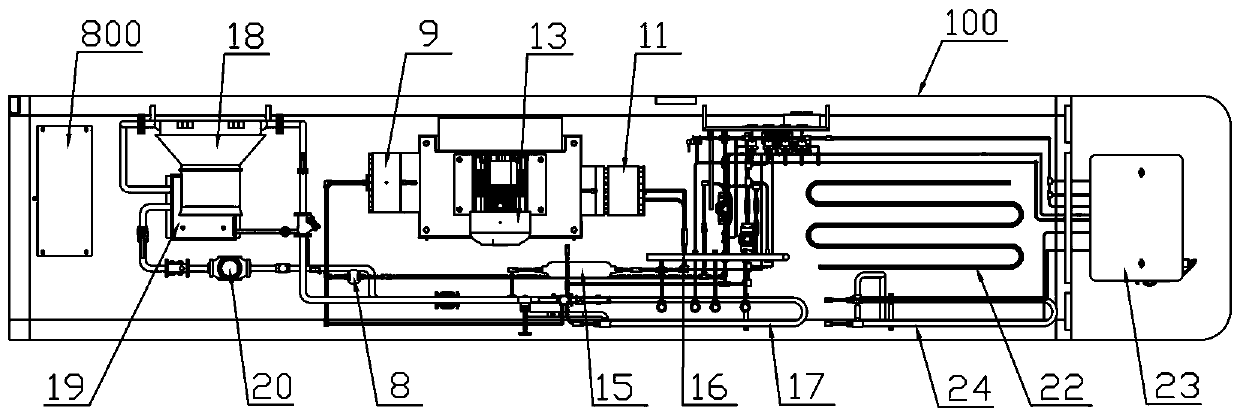

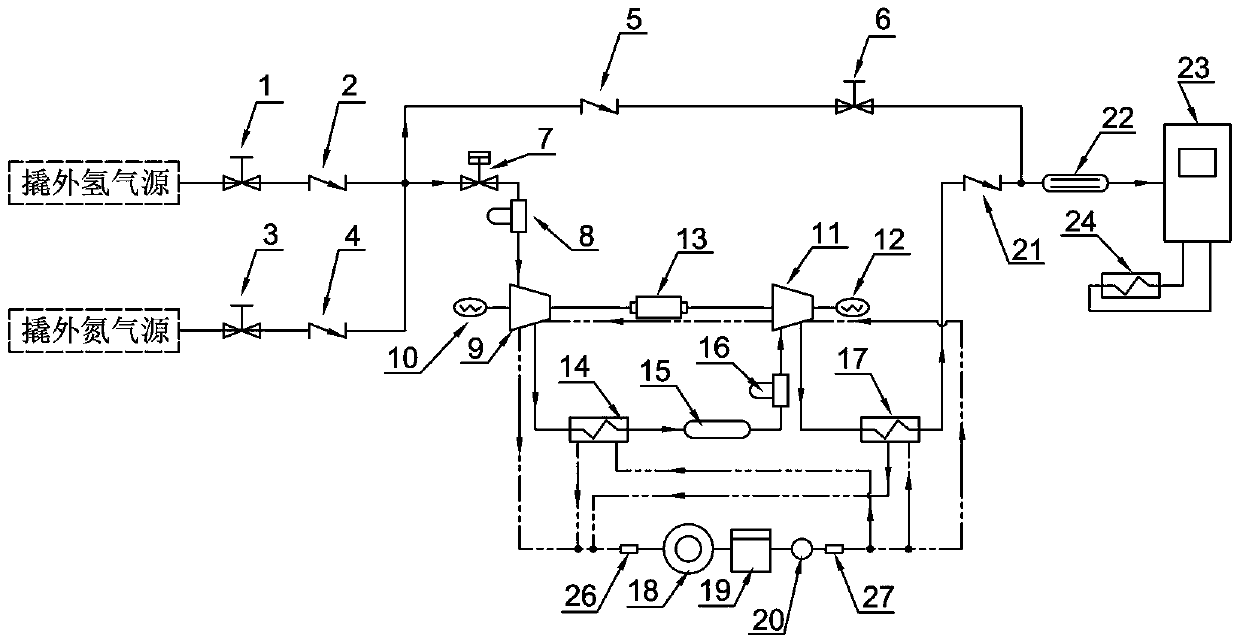

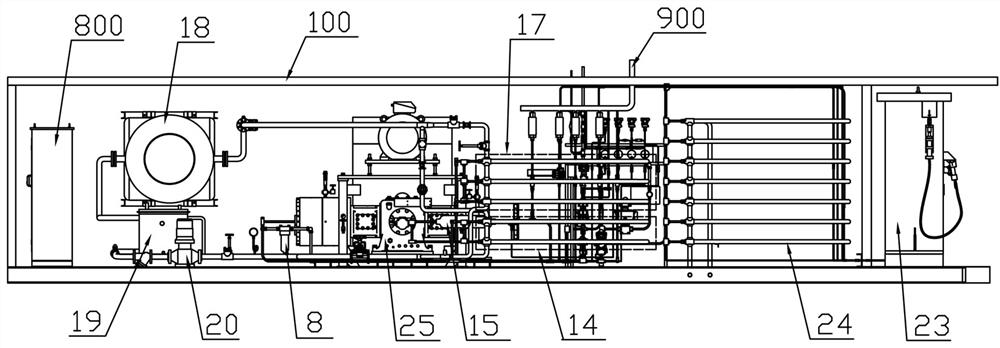

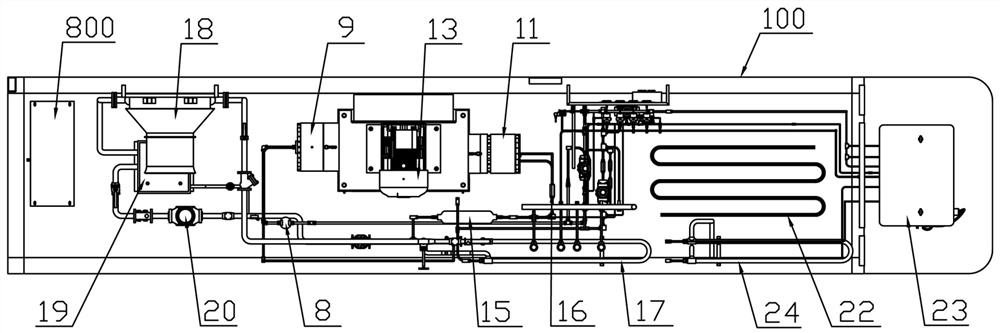

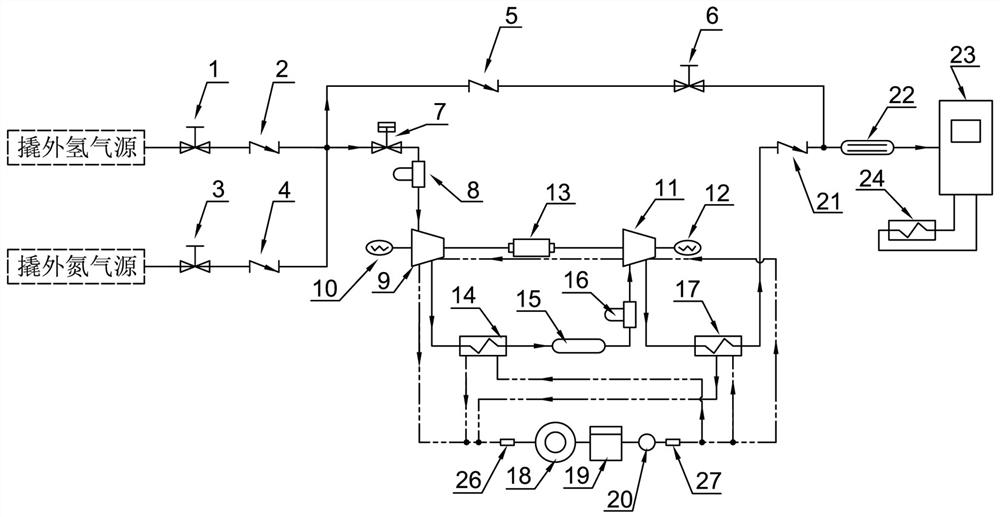

Container skid-type compression hydrogenation device for hydrogen dispenser

PendingCN111336405AImprove filling efficiencySimple structureContainer filling methodsSecondary cellsBuffer tankElectric machinery

The invention discloses a container skid-type compression hydrogenation device for a hydrogen dispenser. The container skid-type compression hydrogenation device comprises a container frame; a compressor integration frame, a first heat exchanger, a second heat exchanger, a buffer tank, an air cooler, a water tank, a water pump and the hydrogen dispenser are fixedly mounted in the container frame;a primary compressor with a leak testing device, a secondary compressor with a leak testing device, and a motor are integrally mounted on the compressor integration frame; the primary compressor and the secondary compressor are both driven by the motor; and the first heat exchanger, the second heat exchanger, the buffer tank, the primary compressor, the secondary compressor, the air cooler, the water tank, the water pump and the hydrogen dispenser achieve functions of hydrogen filling, water cooling circulation and blowing through pipeline connection. All components and pipeline connection inthe device are assembled and debugged in a factory, and can be put into operation through simple debugging in a scene, the structure is simple and compact, the integration degree is high, the occupiedspace is small, transportation is convenient and quick, and the container skid-type compression hydrogenation device can be used as a mobile hydrogen refueling station.

Owner:ZHANGJIAGANG FURUI HYDROGEN ENERGY EQUIP CO LTD +1

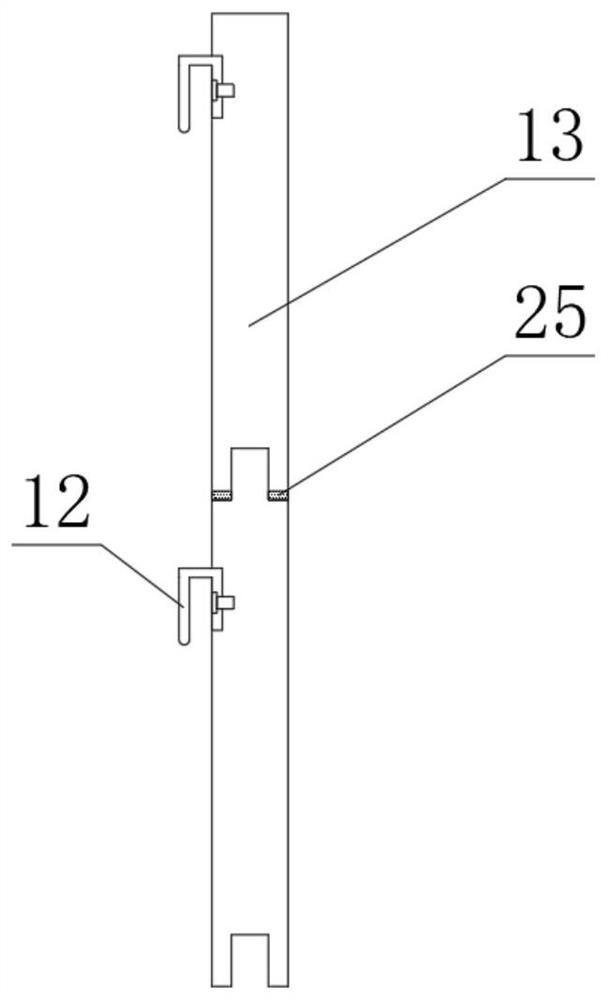

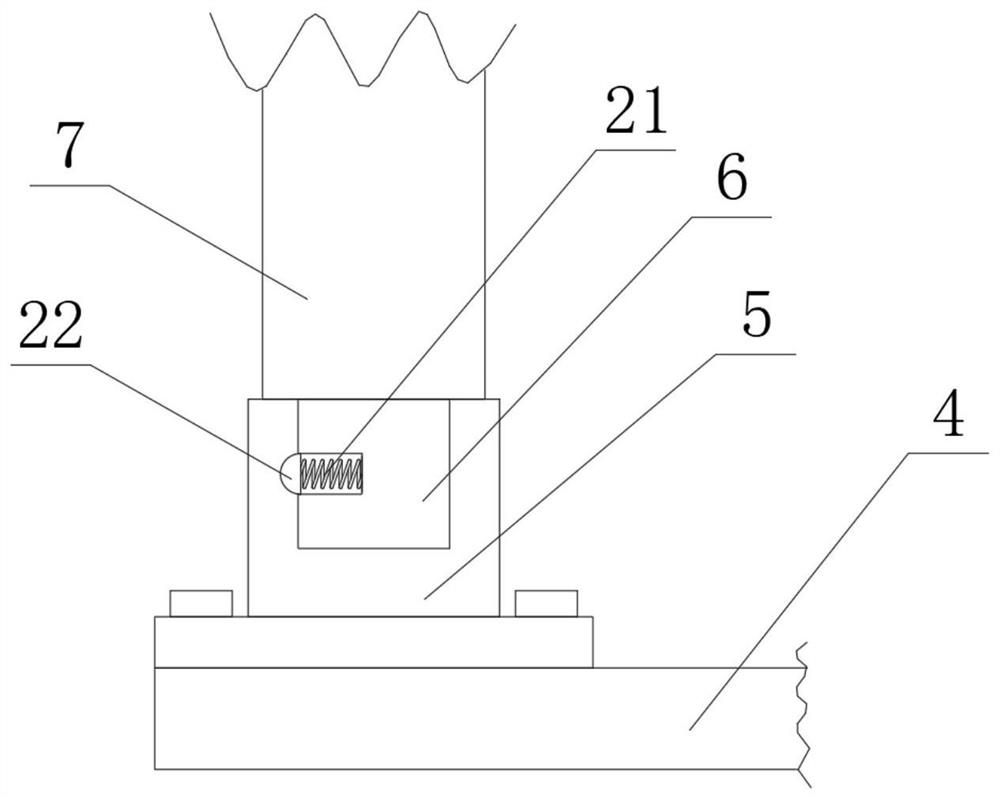

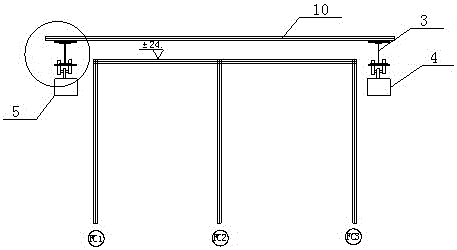

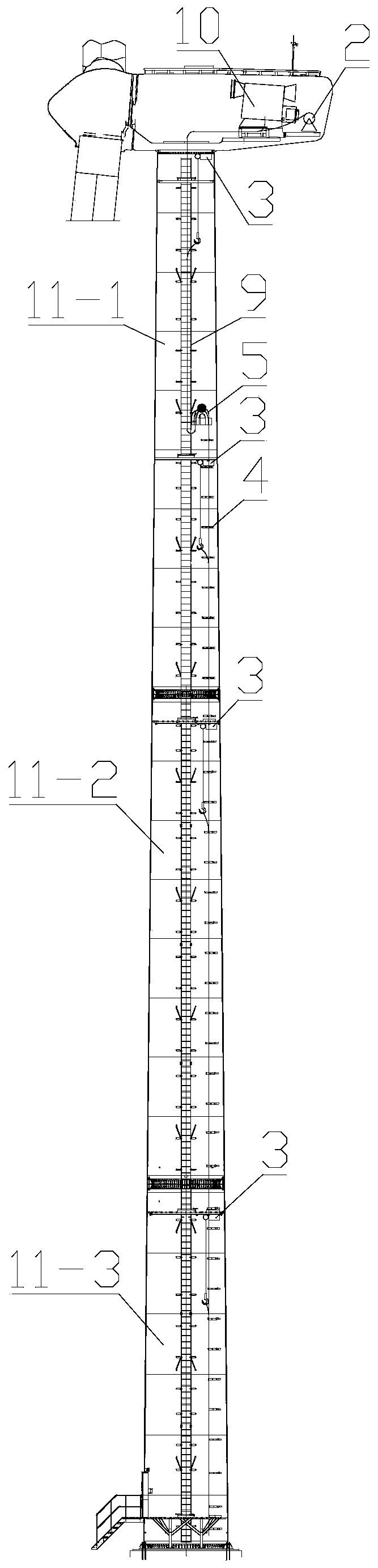

Movable lifting communication base station and construction method thereof

ActiveCN103255937AQuick and easy site buildingShorten the construction cycleTowersBuilding material handlingBase stationArchitectural engineering

A movable lifting communication base station comprises a lifting structure tower, a steel machine room frame, a machine room and a balance weight ground beam. The construction method of the movable lifting communication base station includes steps of 1, investigating a station site; 2, selecting type of the base station; 3, flattening the station site; 4, constructing a cushion layer; 5, transporting and performing site acceptance of finished products; 6, hoisting the balance weight ground beam; 7, hoisting the machine room and the lifting structure tower; 8, lifting the tower body; 9, mounting lightning protection earthing; and 10, checking and accepting. The movable lifting communication base station and the construction method thereof have the advantages that by the construction method, construction is quick and convenient, construction period is greatly shortened, and the movable lifting communication base station is compact in structure, energy-saving, environment-friendly, lower in consumption, recyclable and low in construction cost.

Owner:JUJIANG CONSTR GRP

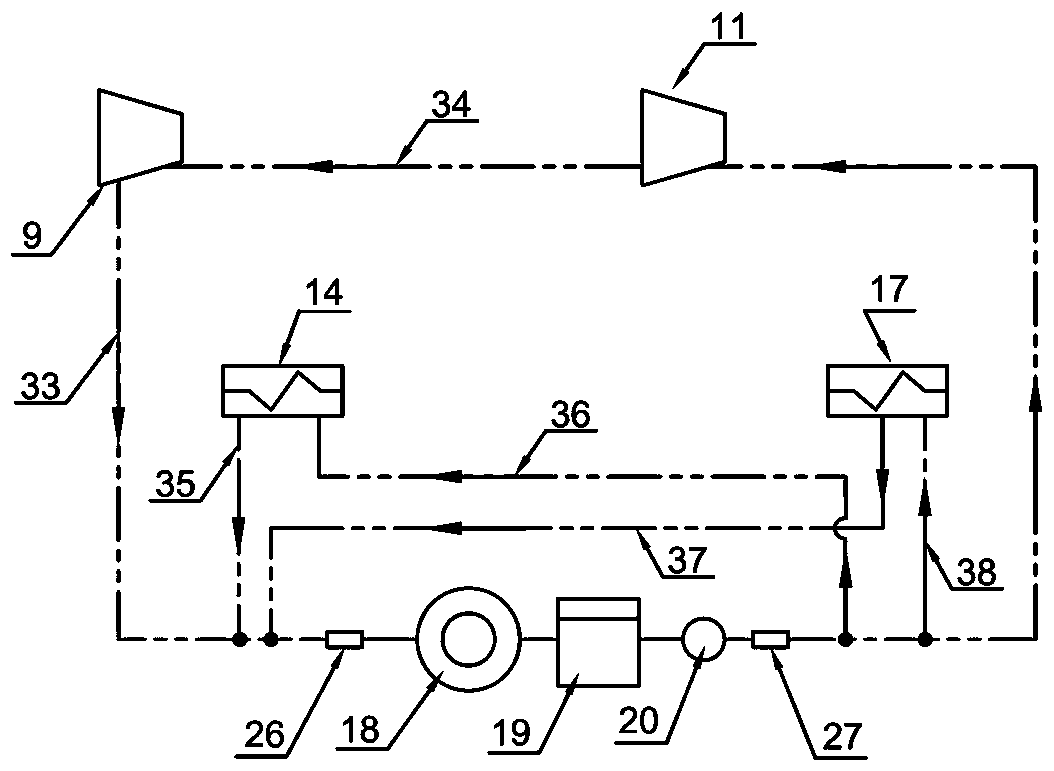

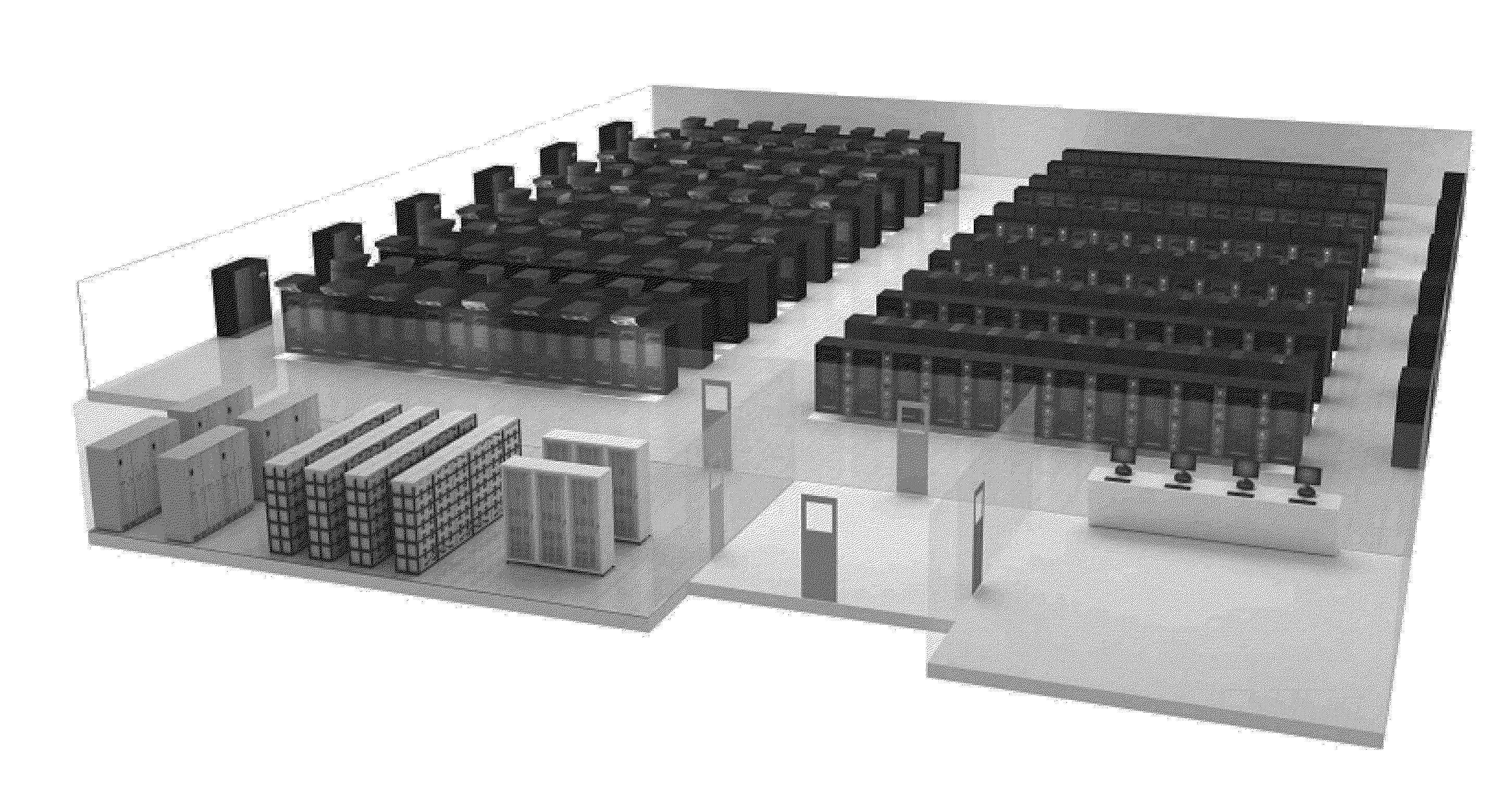

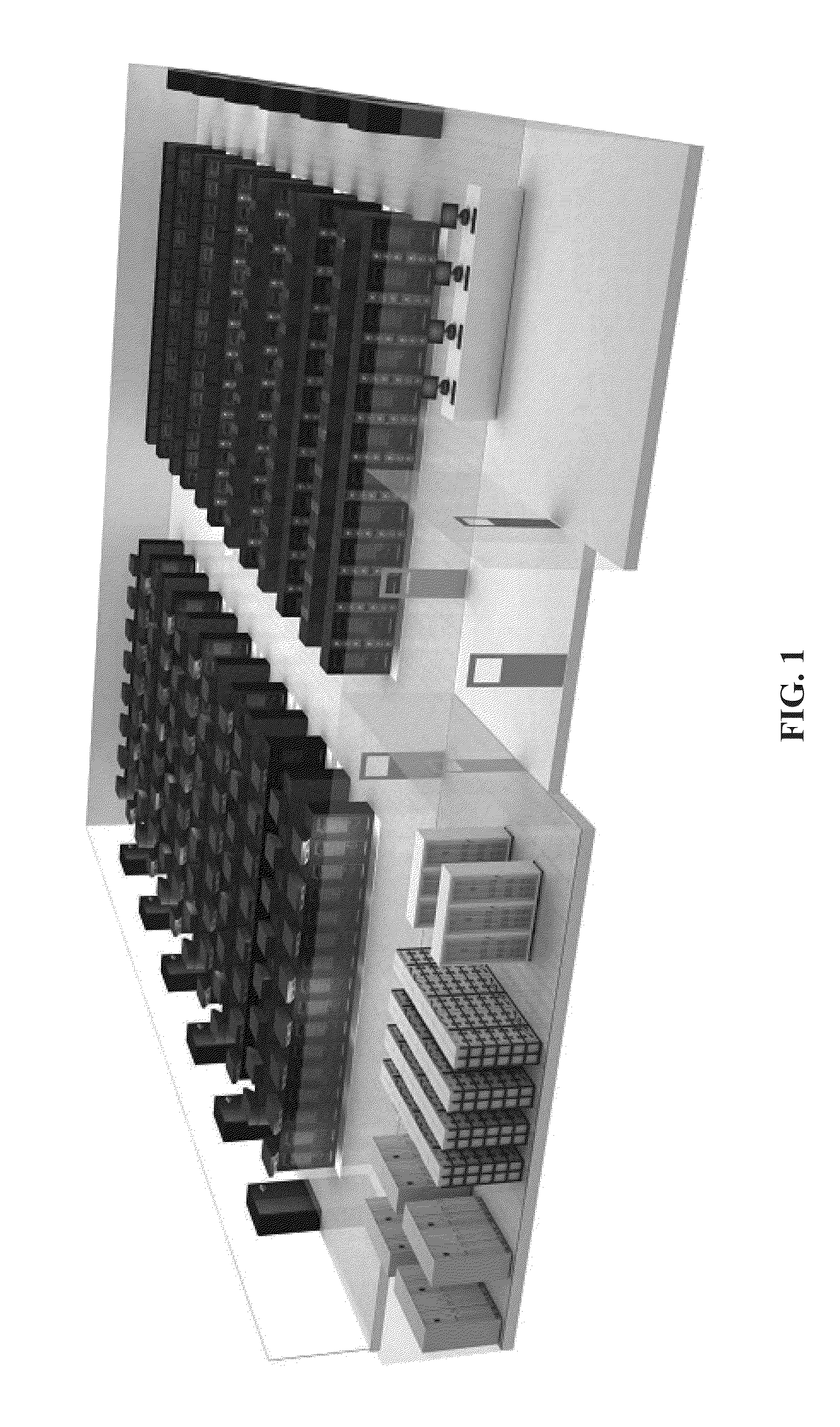

Data center micro-module and data center formed by micro-modules

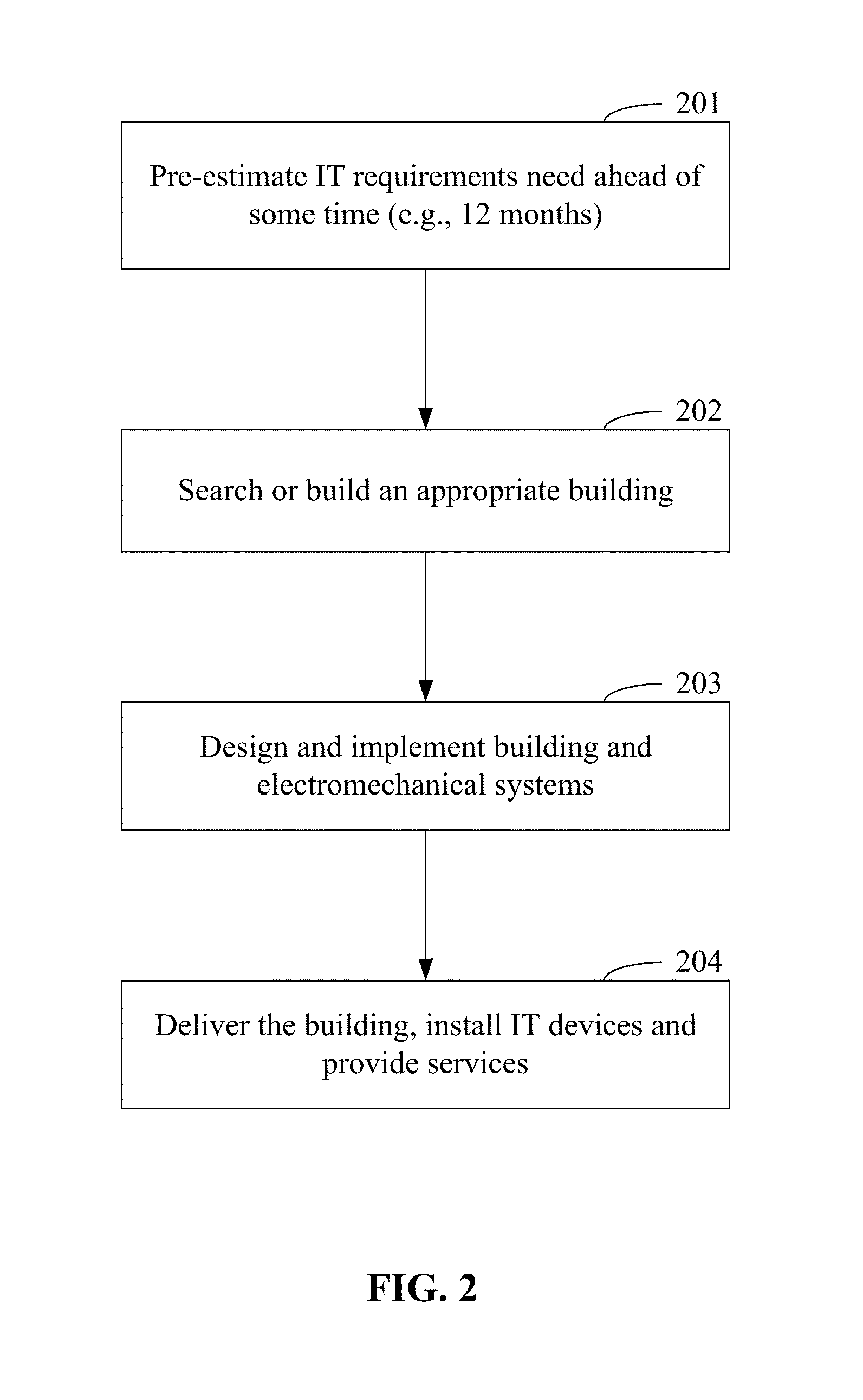

ActiveUS20150359144A1Reduce construction costsShorten the construction cycleServersPower supply for data processingHardware architectureData center

A data center micro-module includes: an enclosure, and a cabinet system, a power supply system, and a cooling system that are inside the enclosure. The cabinet system installs a computing server, the power supply system supplies power for the computing server and the cooling system, and the cooling system cools the computing server; and the enclosure is further externally provided with an interface configured to connect to another data center micro-module or connection apparatus. The foregoing data center micro-module integrates the power supply system, the cooling system and the computing server into a same module, and therefore can be directly manufactured in a factory. When a data center is built, the data center micro-modules only need to be combined and assembled, which greatly reduces a construction cycle of the data center, and the hardware architecture may be flexibly changed according to a specific deployment requirement.

Owner:TENCENT TECH (SHENZHEN) CO LTD

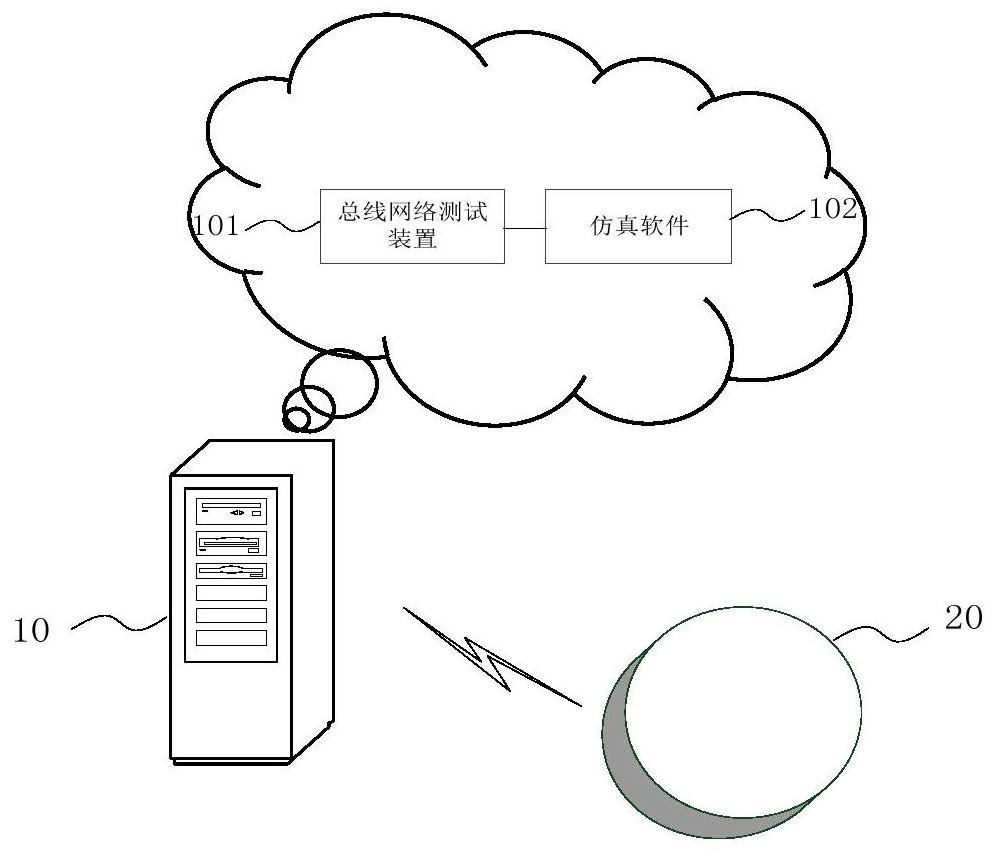

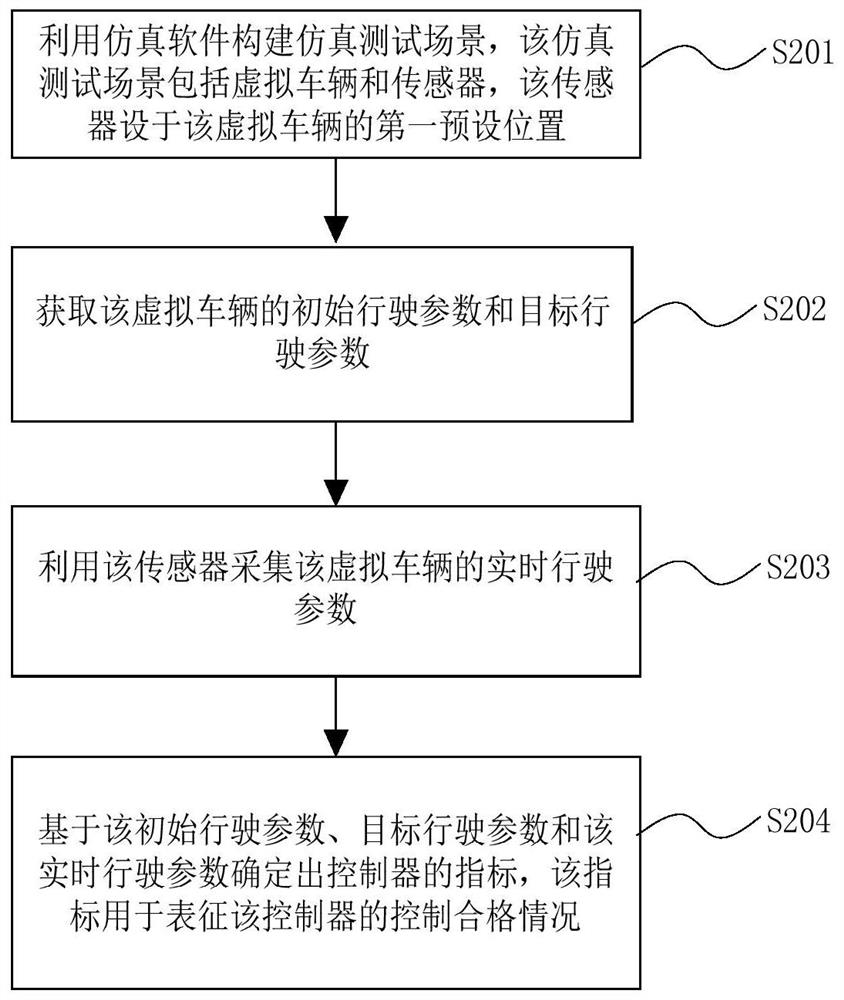

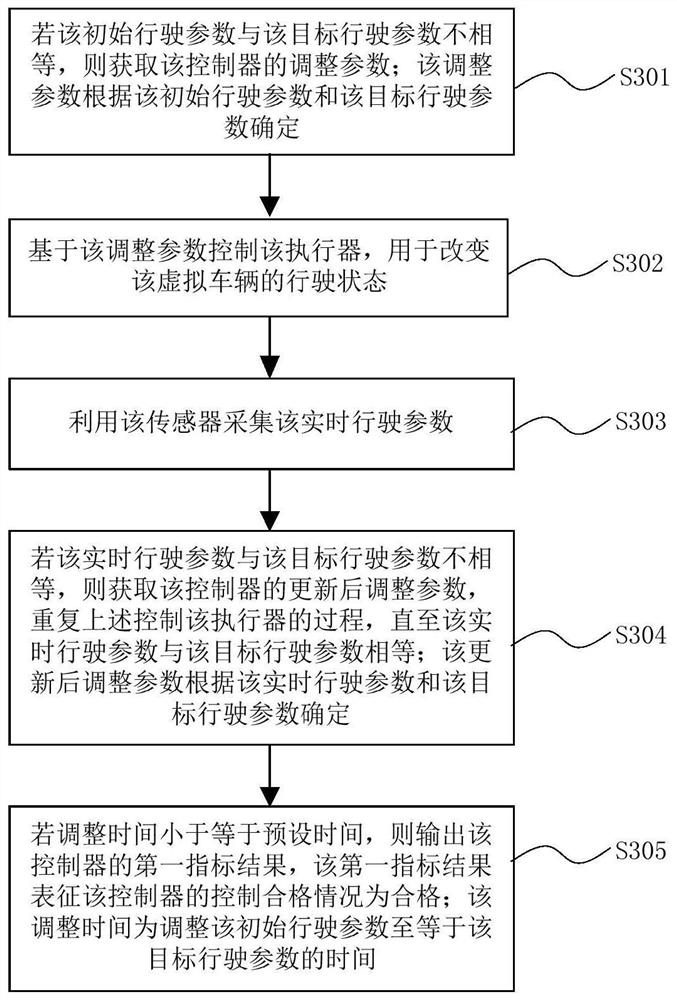

Test method, device and system for intelligent driving and storage medium

PendingCN113704119AShorten the construction cycleShorten test timeSoftware testing/debuggingVirtual vehicleTest scene

The invention relates to the technical field of intelligent driving, and provides a test method, device and system for intelligent driving and a storage medium. According to the test method provided by the invention, a simulation test scene can be constructed by using simulation software, the simulation test scene comprises a virtual vehicle and a sensor, and the sensor is arranged at a first preset position of the virtual vehicle; an initial driving parameter and a target driving parameter of the virtual vehicle are acquired; real-time driving parameters of the virtual vehicle are acquired by using the sensor; and the indexes of the controller are determined based on the initial driving parameters, the target driving parameters and the real-time driving parameters, so that the control qualification condition of the controller can be tested, and the method has the advantage of short test period.

Owner:CHINA AUTOMOTIVE INNOVATION CORP

Container skid-mounted compression hydrogenation device

ActiveCN111486344AEven by forceShorten the pipe lengthVessel mounting detailsContainer filling methodsBuffer tankElectric machinery

The invention discloses a container skid-mounted compression hydrogenation device. A container integration framework is fixedly installed in the middle part of a bottom frame of a container frame, a motor is located in the middle of the upper layer of the container integration framework, a primary compressor and a secondary compressor are arranged side by side on the lower layer of the container integration framework and arranged in a manner of front-and-back symmetry relative to the motor, and the primary compressor and the secondary compressor are driven by the motor. A water tank, a water pump, an air cooler and an electric control cabinet are fixedly arranged on the bottom frame behind the container integration framework. A first heat exchanger, a second heat exchanger, a third heat exchanger, a buffer coil pipe and a hydrogenator are arranged on the bottom frame in the front of the container integration framework, the first heat exchanger and the second heat exchanger are distributed in an up-and-down manner, and the third heat exchanger and the buffer coil pipe are arranged in the left-and-right direction. A buffer tank, a gas pipeline system and a cooling pipeline system arearranged at the space positions of the container integration framework. The container skid-mounted compression hydrogenation device is simple and compact in structure, the overall layout is balancedin the front-and-back direction, and the center of gravity is centered.

Owner:ZHANGJIAGANG FURUI HYDROGEN ENERGY EQUIP CO LTD +1

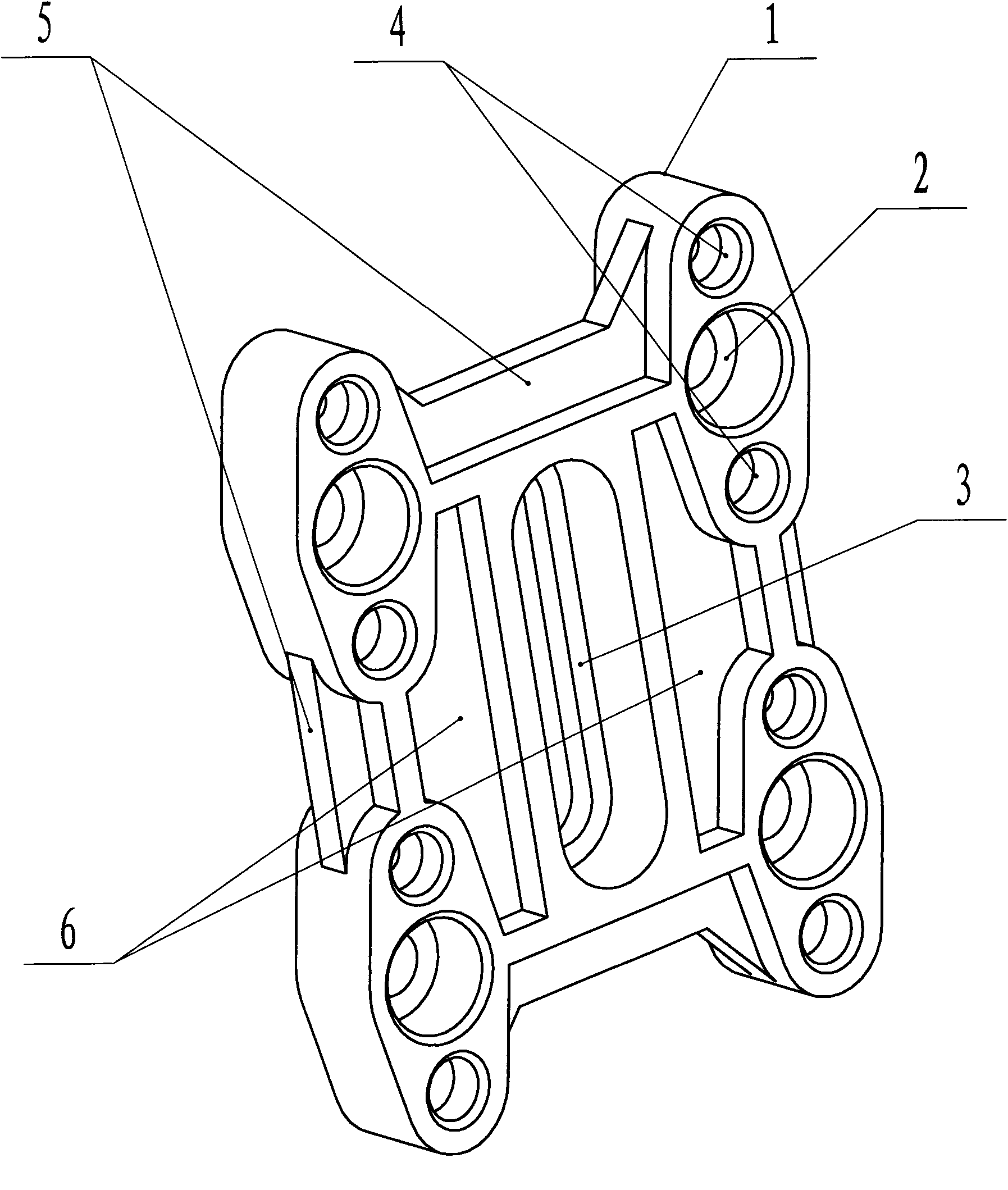

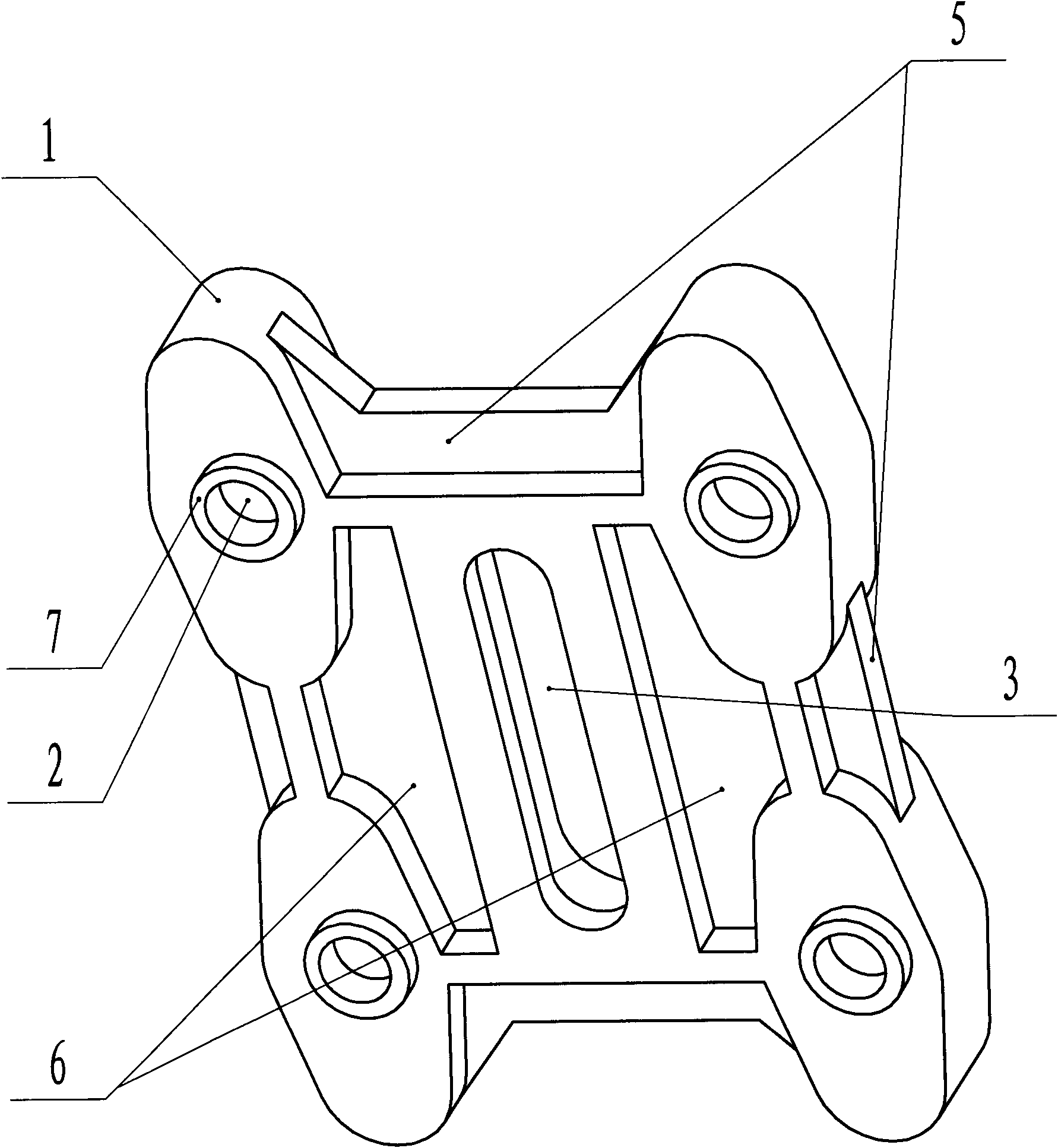

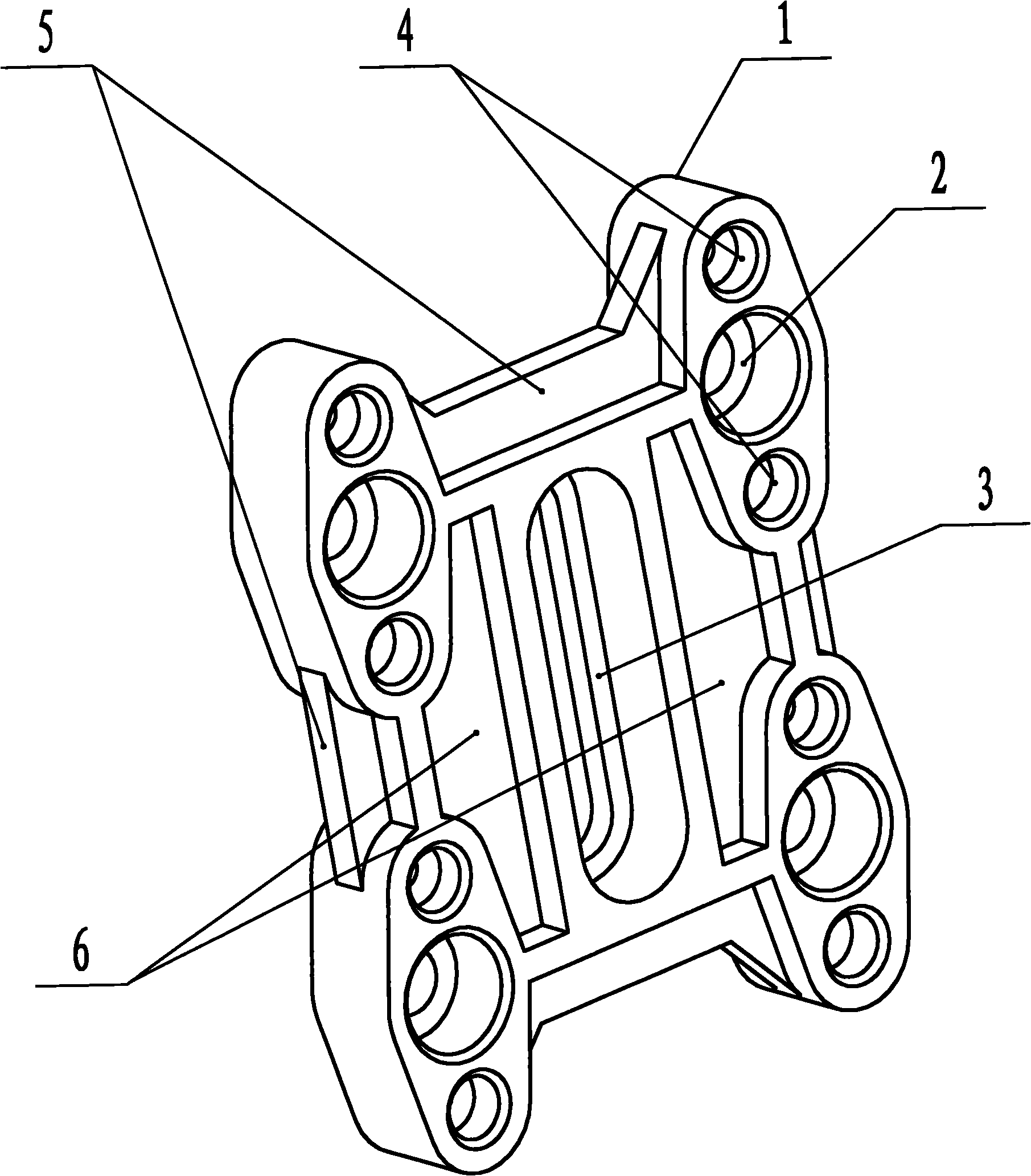

Connecting fastener

The invention discloses a connecting fastener. The fastener comprises a connection piece body, and is characterized in that the connection piece body is in an H shape; through holes are respectively arranged at the middle part and four corners of the connection piece body, and the through holes at the four corners are stepped through holes; two positioning blind holes are respectively arranged beside each through hole positioned at the four corners of the connection piece body; the through holes positioned at the middle part of the connection piece body are stepped kidney-shaped through holes; a reinforcing rib is arranged at the periphery of the connection piece body; and the connection piece body is equipped with blind slots. The connecting fastener has the advantages of simple, reasonable, practical and novel structure, interchangeability and generality, and is accurate in location and reliable in installation; and by utilizing the connecting fastener, a display unit realizes 'spliced joints' with zero clearance or micro-clearance and uniform clearance as well as high flatness during the screen assembly process, thus preventing display images from being distorted and overcoming the situation of dead space in visual angles of the display screen caused by local projection or dent of a large screen.

Owner:桂林海威科技股份有限公司

Quick method for orchard establishment by current-year direct seeding grafting of pistachio

InactiveCN102057850APromote growthRaise the ground temperatureCultivating equipmentsHorticultureRootstockBud

The invention discloses a quick method for orchard establishment by current-year direct seeding and grafting of pistachio. The method comprises the following steps: selecting pistachio seeds and storing in sand for 40 days before seeding; accelerating germination at the constant temperature of 20 DEG C until the seeds sprout; ridging towards the north-south direction and seeding; ridging according to the fixed plant row space, wherein the ridge height is 30 cm, the upper width is 20-30 cm, and the bottom width is 40-50 cm; punching 8 cm-depth seeding holes with a hole puncher on the ridge according to the 3-4 m plant distance; dibbling 2-3 seeds after germination acceleration into each hole; covering the seeds with fine wet soil and paving a film on the ridge; grating when the root thickness of the plant reaches 0.5 cm; performing T-shaped bud grafting with the scions with full eyes at 5-10 cm away from the ground; pruning rootstock and disbudding after the bud grafting; pinching whenthe scion germinated branch grows to 40-50 cm; and hilling at the trunk root for 40-50 cm. According to the invention, annual orchard establishment by current-year seeding and current-year grafting is realized, and the seedling survival rate is beyond 95%. Thus, basis is provided for large-area popularization and cultivation of pistachio.

Owner:HORTICULTURE INST OF XINJIANG ACAD OF AGRI SCI

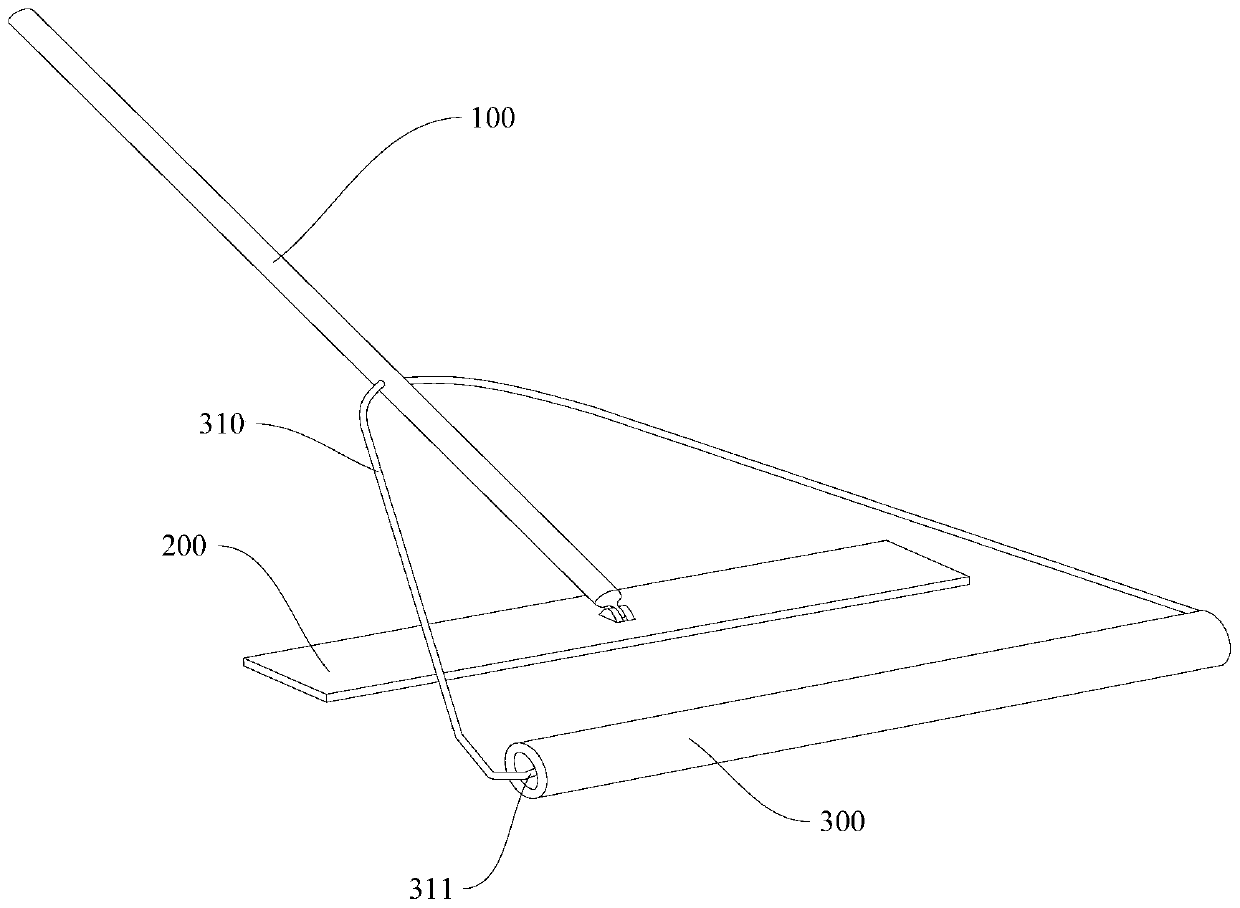

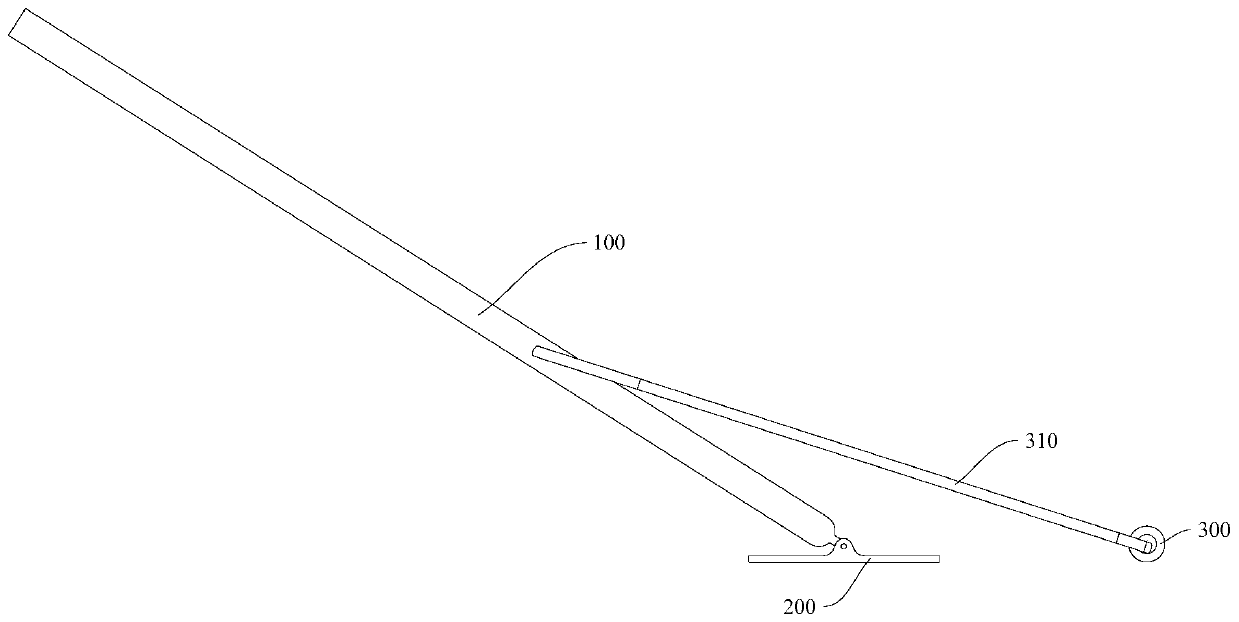

Leveling and troweling and film covering maintenance integrated equipment

InactiveCN111395713AQuality assuranceShorten the construction cycleBuilding material handlingEngineeringStructural engineering

Owner:CHINA MCC5 GROUP CORP

Method for grafting different stock tender branches of pinus sylvestris

The invention discloses a method for grafting different stock tender branches of pinus sylvestris. The method comprises the following steps: taking pinus sylvestris as stock, selecting branches of which the terminal buds are full and needle leaves are remained intact as scions, wherein the coarseness of the scions is 2 / 3 of the coarseness of a main branch of the stock even the same coarseness; removing other needle leaves along a growth direction of the needle leaf, obliquely cutting from a position which is about 0.5cm away from the bearing position of the remained needle leaf by blades, enabling the cutting depth to reach the pith of the scion, peeling off a bark along the phloem and xylem on a main one-year-old branch of the stock, aligning the peeled scion joint and the stock cut fromthe left to right, trimming the stock in the next year after grafting success and before treetop germination, and unbundling all the grafted planted after stock trimming completion so as not to avoidnormal thickening growth of the stock. The method disclosed by the invention has the beneficial effects that the breeding ability of the pinus sylvestris is greatly improved, excellent characteristicsof the pinus sylvestris are maintained, the stock breeding cost is reduced, the orchard establishment period is shortened, and ecological benefits of the pinus sylvestris are realized in advance.

Owner:陕西省治沙研究所

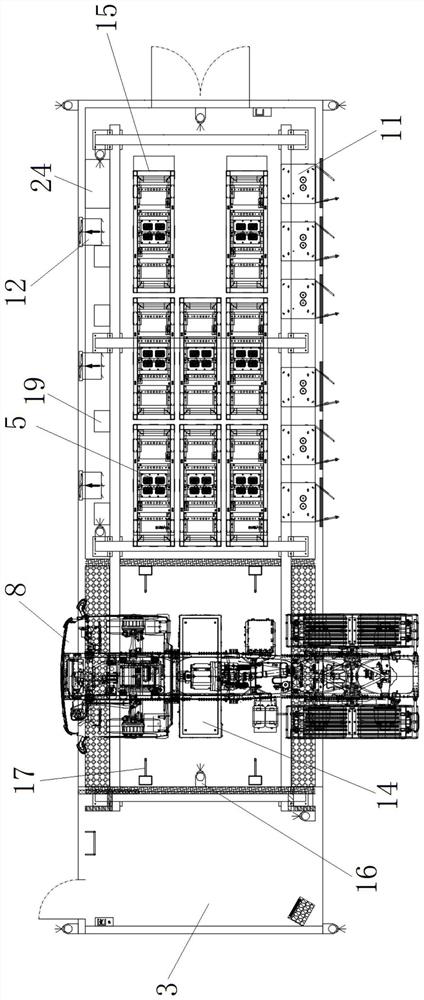

Commercial vehicle fixed charging and battery swapping station

PendingCN113910972AImprove space utilizationCompact layoutCharging stationsVehicular energy storageEngineeringControl room

The invention relates to the technical field of charging and battery swap stations, and provides a commercial vehicle fixed charging and battery swapping station which comprises a first area and a second area, and the first area comprises a maintenance room layer, a main control room layer and a rest room layer which are sequentially arranged from top to bottom in the height direction of the first area; the second area is as high as the first area, the second area comprises a battery storage area, a driving channel and a hoisting mechanism, the driving channel is located between the battery storage area and the first area, and the hoisting mechanism is located above the battery storage area and the driving channel; and the hoisting mechanism is used for hoisting the fully-charged battery in the battery storage area to the battery replacing vehicle in the driving channel, and the hoisting mechanism is matched with the maintenance room layer for maintenance. By arranging the maintenance room layer, the main control room layer, the rest room layer, the battery storage area, the driving channel and the hoisting mechanism, the space is integrated and utilized, the layout is compact, the space utilization rate is high, the functions are diversified, the occupied area is reduced, the station building period is shortened, and the construction amount is reduced.

Owner:三一锂能有限公司

Construction process of foam concrete light roadbed above subway tunnel

The invention discloses a construction process of a foam concrete light roadbed above a subway tunnel. The method comprises the steps that S1, a construction roadbed is excavated, and a filling area is preset; S2, a base of the filling area is cleaned and leveled; S3, graded broken stone is laid; S4, formwork erecting and bin dividing are carried out ; S5, a first layer of foam concrete is poured;S6, a reinforcing mesh is laid; S7, a next layer of foam concrete is poured; S8, a next layer of reinforcing mesh is laid; S9, the last layer of foam concrete is poured; and S10, water is sprayed formaintenance. By means of the construction process, the additional stress generated by rail-related section roadbed filling on the running subway shield tunnel is smaller than the numerical value required by the rail department, the safety of roadbed construction above the running subway shield tunnel is improved, and compared with traditional lime soil roadbed construction, the construction operation period is greatly shortened, and the additional stress generated by roadbed filling on the running subway shield tunnel is reduced.

Owner:SUZHOU ZHONGHENGTONG ROAD & BRIDGE GRP CO LTD

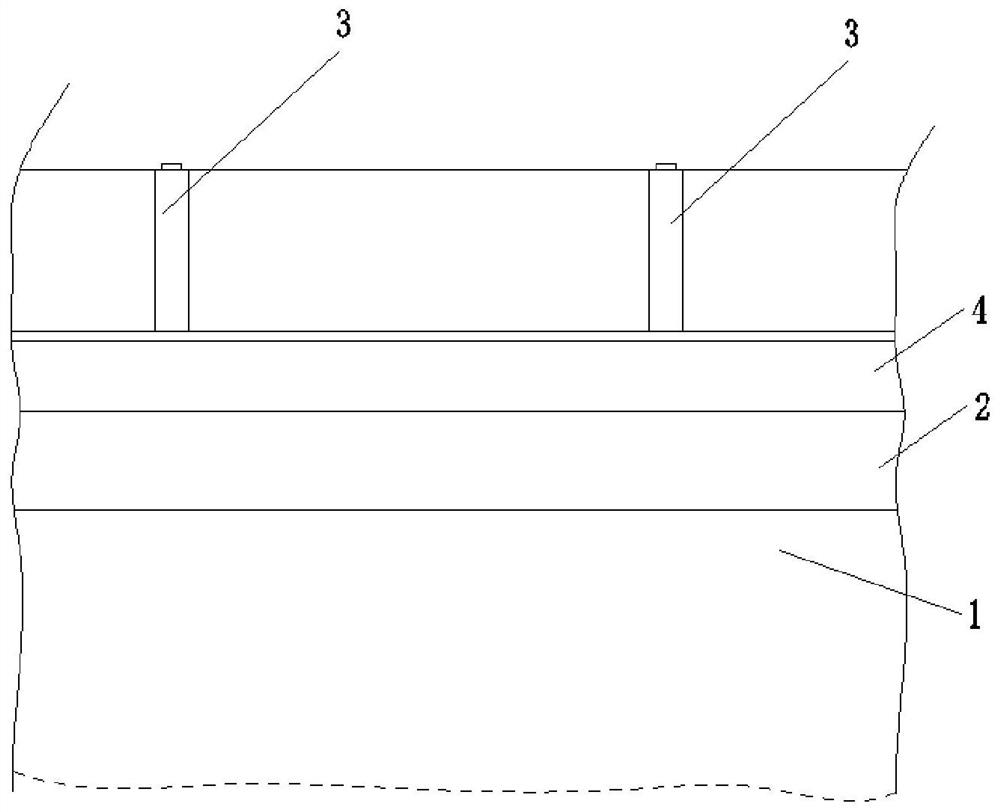

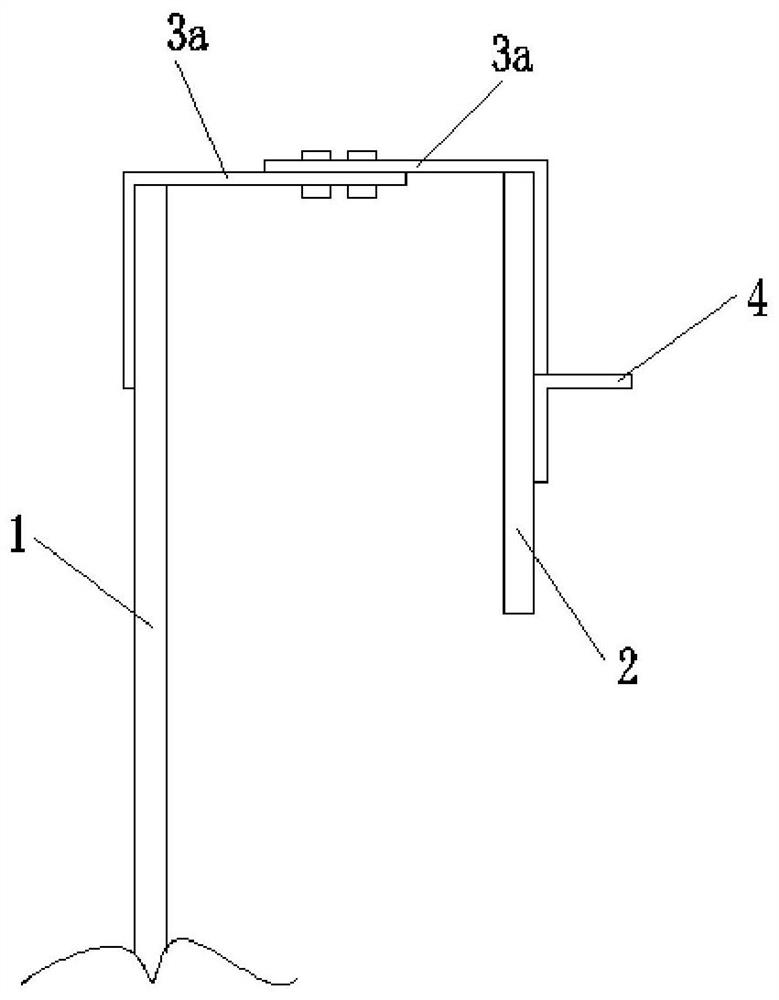

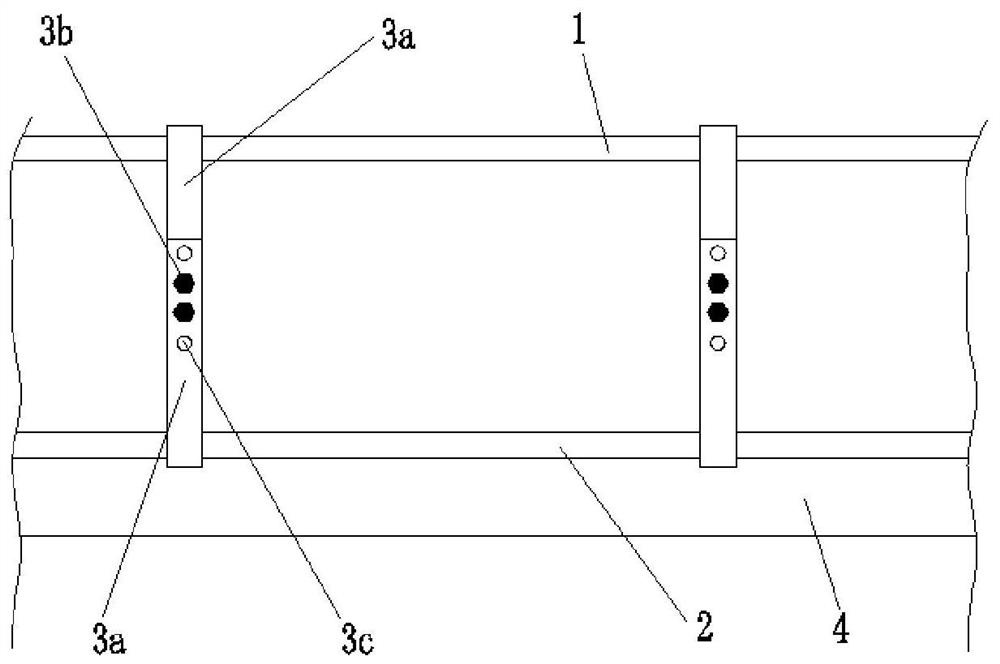

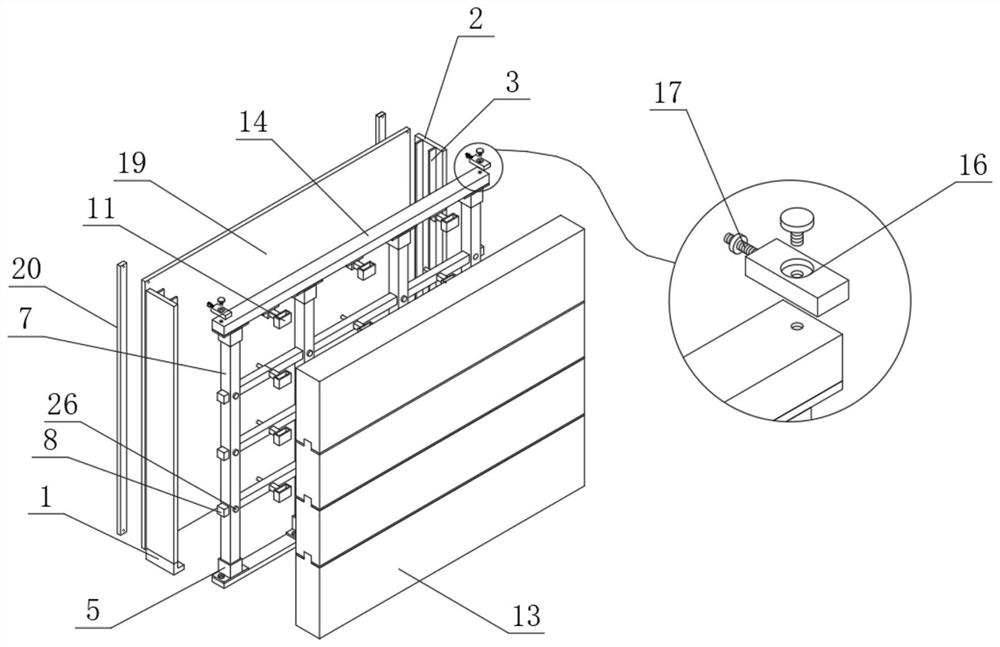

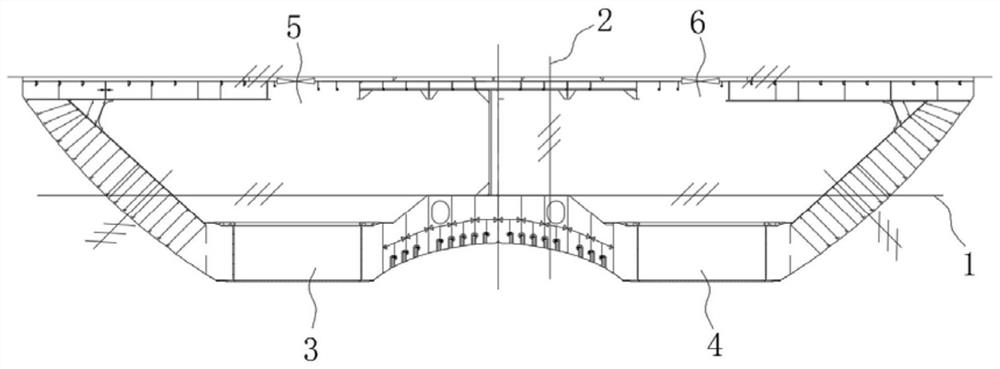

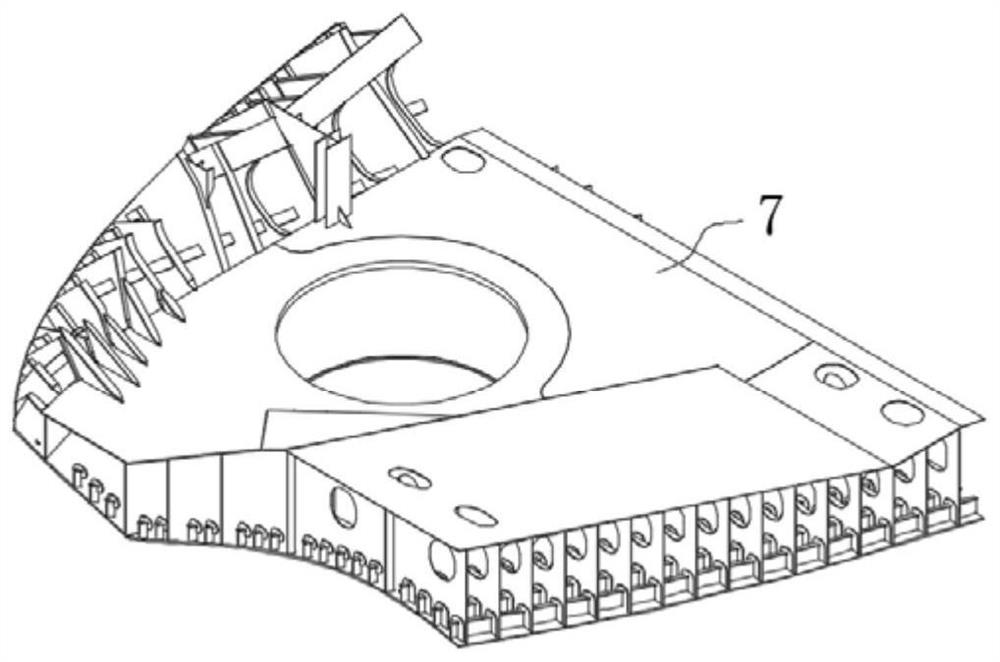

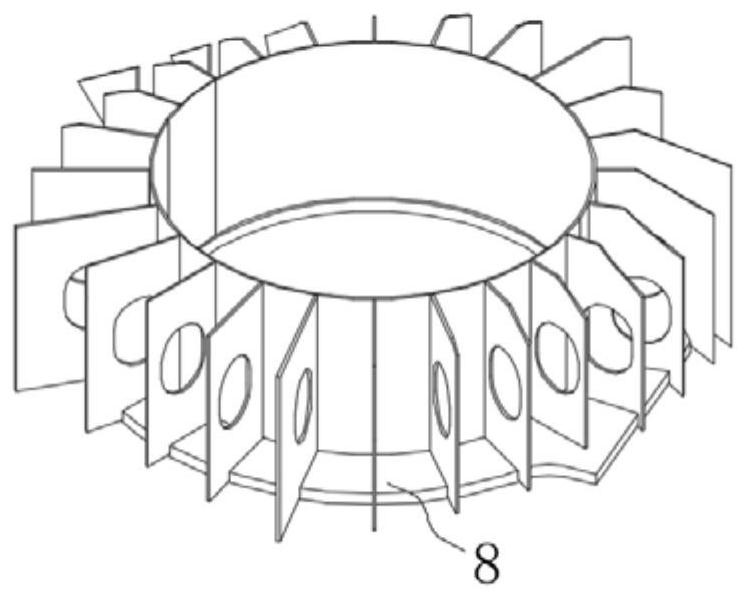

Sound barrier foundation and box girder integrated pouring template

ActiveCN110565529ARealize integrated pouringSimplify construction work stepsNoise reduction constructionBridge erection/assemblySound barrierSheet steel

The invention discloses a sound barrier foundation and box girder integrated pouring template. A sound barrier foundation outer template is formed in the manner than a box girder outer template overall extends upwards and is heightened. A sound barrier foundation inner template adopts a rectangular steel plate as long as the sound barrier foundation outer template. The sound barrier foundation outer template and the sound barrier foundation inner template are connected through multiple n-shaped connecting components arranged at equal intervals in the length direction. Each n-shaped connectingcomponent is formed in the manner than two pieces of oppositely-arranged strip-shaped angle steel are spliced by being combined with bolts after top face stacking, wherein the vertical face of one piece of strip-shaped angle steel and the vertical face of the sound barrier foundation outer template are welded, and the vertical face of the other piece of strip-shaped angle steel and the vertical face of the sound barrier foundation inner template are welded. The grinding procedure of the outer side of a sound barrier foundation is omitted, the aerial near-edge work is reduced, and safety risksare reduced; and the number of times of template mounting and concrete pouring is reduced, construction time is saved, the input of labor force is reduced, and work efficiency and engineering benefitsare improved.

Owner:江苏中车城市发展有限公司 +1

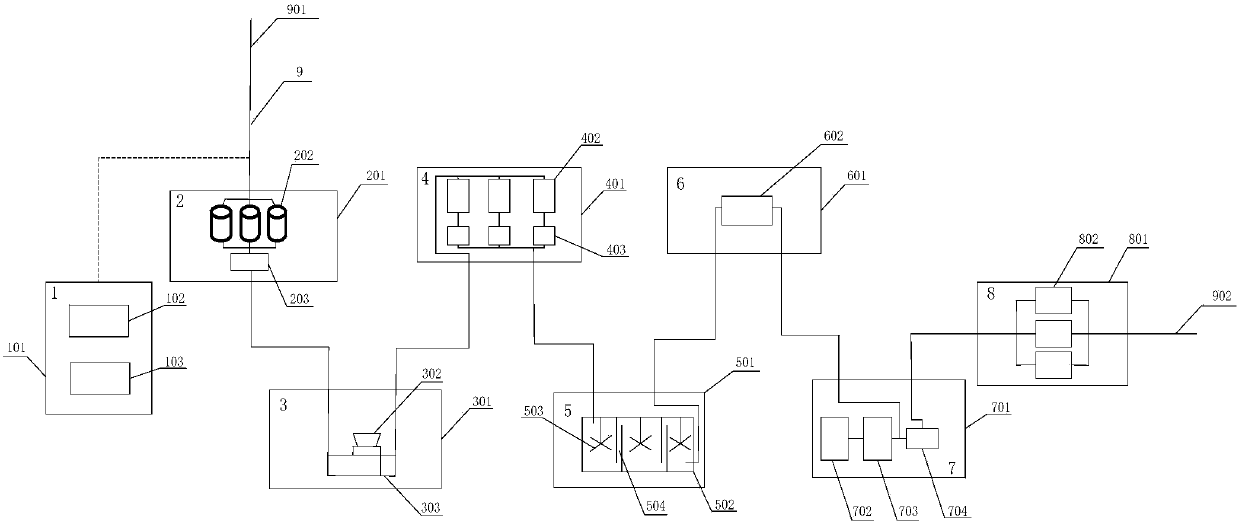

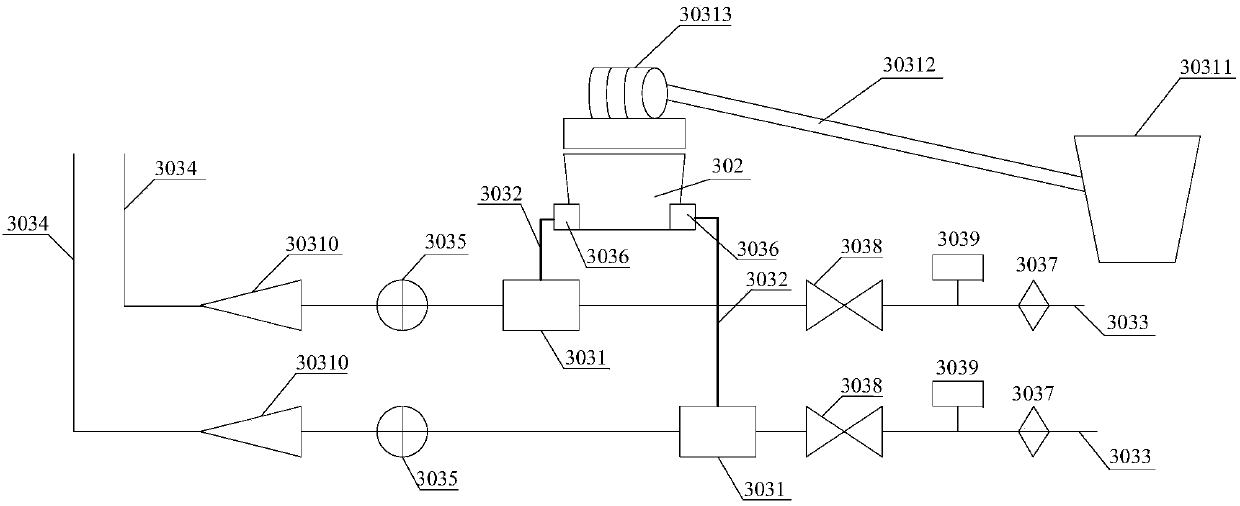

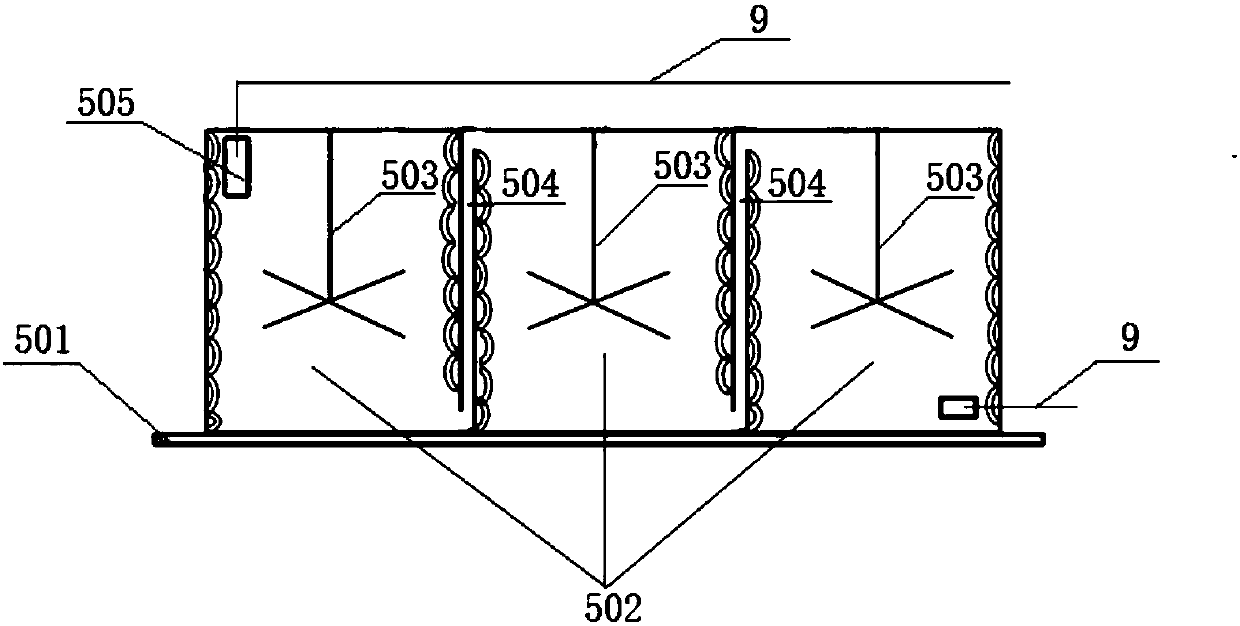

Skid-mounted modularized polymer-surfactant binary drive injection allocation device applicable to complex fault block oil field

The invention discloses a skid-mounted modularized polymer-surfactant binary drive injection allocation device applicable to a complex fault block oil field and belongs to the technical field of tertiary oil recovery. According to the skid-mounted modularized polymer-surfactant binary drive injection allocation device applicable to the complex fault block oil field, a moveable produced water deeptreatment module, a moveable polymer dry powder dispersion module, a moveable auxiliary agent addition module, a moveable polymer mother liquid on-line aging module, a moveable feeding module, a moveable surfactant storage dilution and addition module and a moveable injection module are sequentially arranged at the liquid inlet end and the liquid outlet end of a first pipeline, a moveable power supply and distribution and automation control module is arranged at the liquid inlet end of the first pipeline, then power support and automatic control are provided for the modules, a standardized andmodularized polymer injection binary drive injection allocation device is established, industrial manufacturing and production can be achieved, the station construction period of a polymer injectionbinary drive injection allocation station is shortened, and convenience is brought to on-site management and repeated multi-time use.

Owner:PETROCHINA CO LTD

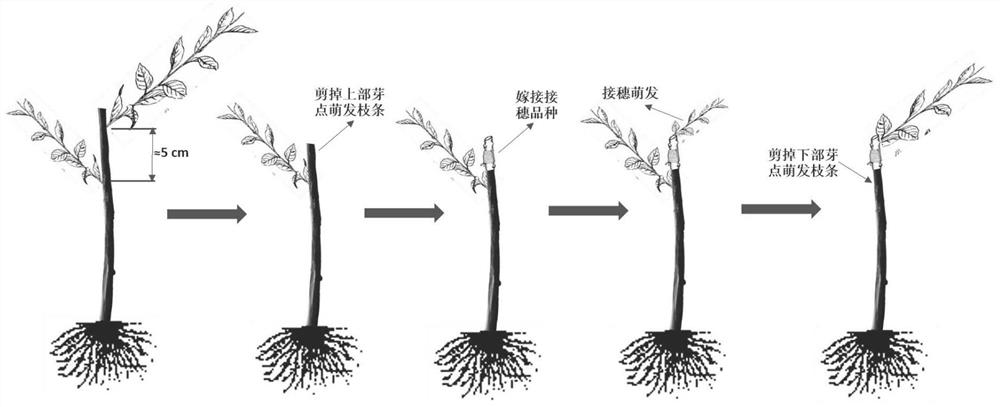

A fast breeding method of kiwi grafting seedlings

The invention relates to the technical field of agriculture, in particular to a rapid breeding method for grafted seedlings of kiwifruit. The breeding method of the present invention includes the steps of selection of rootstock seedlings, cultivation of rootstock seedlings, selection of scions, grafting of scions, management of grafted seedlings and the like. The method has the following advantages: 1) it is easy to operate and master; 2) it shortens the breeding time of seedlings, improves the quality of seedlings, and saves management costs; 3) is conducive to cultivating robust seedlings, shortens the period of garden construction, and realizes early benefits of early gardening. The method can also provide reference for the seedling breeding methods of other fruit trees, especially the fruit trees that are bred with seedlings by grafting.

Owner:ZHENGZHOU FRUIT RES INST CHINESE ACADEMY OF AGRI SCI

Integrated pouring formwork for sound barrier foundation and box girder

ActiveCN110565529BRealize integrated pouringSimplify construction work stepsNoise reduction constructionBridge erection/assemblySound barrierArchitectural engineering

The invention discloses an integrated pouring formwork for a sound barrier foundation and a box girder. The outer formwork of the sound barrier foundation is formed by extending and heightening the outer formwork of the box girder as a whole, and the inner formwork of the sound barrier foundation adopts the same length as the outer formwork of the sound barrier foundation. Rectangular steel plates, the outer formwork of the sound barrier foundation and the inner formwork of the sound barrier foundation are connected by a number of П-shaped connecting members arranged at equal intervals along the length direction, and the П-shaped connecting member is laminated by two oppositely arranged strip angle steels through the top surface. It is spliced together with bolts, the facade of one piece of strip angle steel is welded to the facade of the outer formwork of the sound barrier foundation, and the facade of the other piece of strip angle steel is welded to the facade of the inner formwork of the sound barrier foundation. Eliminate the external grinding process of the sound barrier foundation, reduce high-altitude edge operations, and reduce safety risks; reduce the number of formwork installation and concrete pouring, save construction time and labor input, and improve operating efficiency and engineering benefits.

Owner:江苏中车城市发展有限公司 +1

Movable lifting communication base station and construction method thereof

ActiveCN103255937BLow costWill not polluteTowersBuilding material handlingArchitectural engineeringTower

A movable lifting communication base station comprises a lifting structure tower, a steel machine room frame, a machine room and a balance weight ground beam. The construction method of the movable lifting communication base station includes steps of 1, investigating a station site; 2, selecting type of the base station; 3, flattening the station site; 4, constructing a cushion layer; 5, transporting and performing site acceptance of finished products; 6, hoisting the balance weight ground beam; 7, hoisting the machine room and the lifting structure tower; 8, lifting the tower body; 9, mounting lightning protection earthing; and 10, checking and accepting. The movable lifting communication base station and the construction method thereof have the advantages that by the construction method, construction is quick and convenient, construction period is greatly shortened, and the movable lifting communication base station is compact in structure, energy-saving, environment-friendly, lower in consumption, recyclable and low in construction cost.

Owner:JUJIANG CONSTR GRP

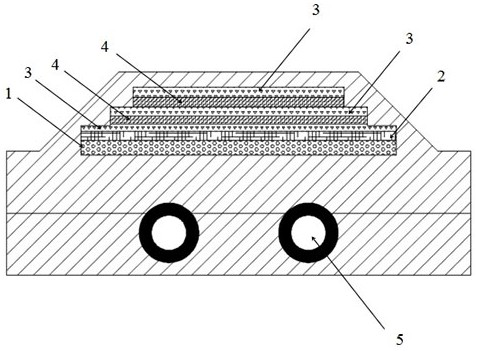

Wall surface mounting structure based on fabricated keels

The invention discloses a wall surface mounting structure based on fabricated keels. The wall surface mounting structure comprises a base, wing plates, positioning plates, a ground keel, connecting seats, connectors and vertical keels. Through holes are formed in one sides of the vertical keels, center-penetrating keels are movably connected into the through holes, inserting holes are formed in the front surfaces of the center-penetrating keels, fixing rods are movably connected into the inserting holes, connecting rods are fixedly connected to one ends of the fixing rods, lantern rings are fixedly connected to one ends of the connecting rods, inserting plates are movably connected into the lantern rings, and wall surfaces are fixedly connected to one sides of the inserting plates. The wall surface mounting structure based on the fabricated type keels has the main advantages that the time for waiting for concrete solidification in a traditional construction mode is avoided, concrete stirring operation needing to be conducted on a construction site is reduced, flying dust on the construction site is reduced, the construction environment of workers is improved, and the construction period of the building wall surface is shortened.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

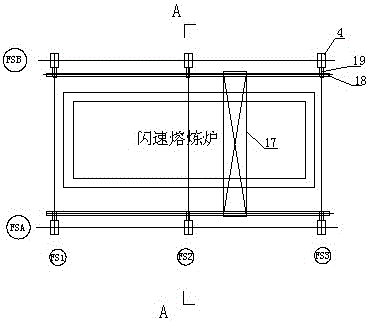

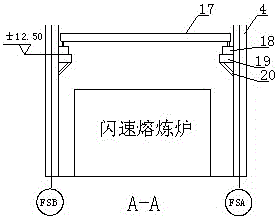

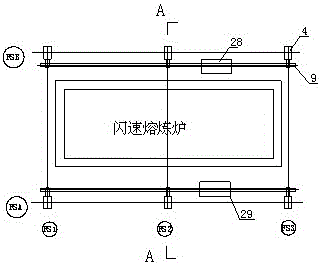

An Improved Installation Method of Flash Converting Furnace

ActiveCN104675116BHigh control precisionShorten the construction cycleBuilding material handlingLifting gasEngineering

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

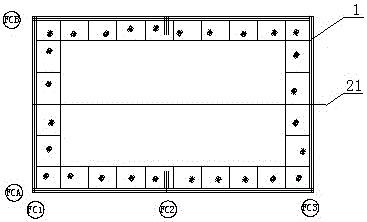

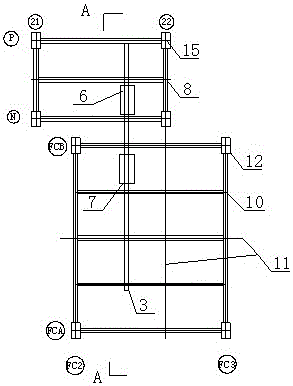

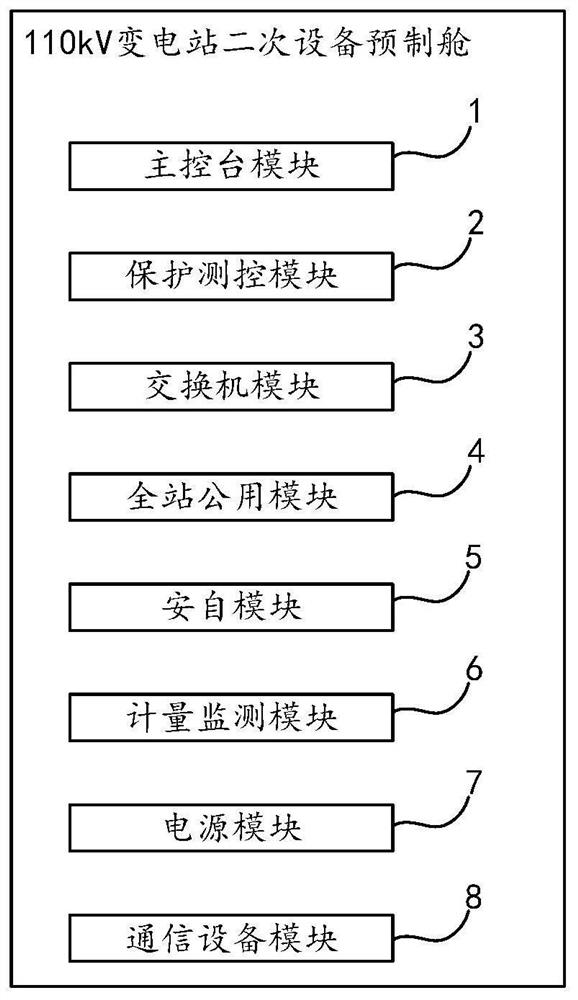

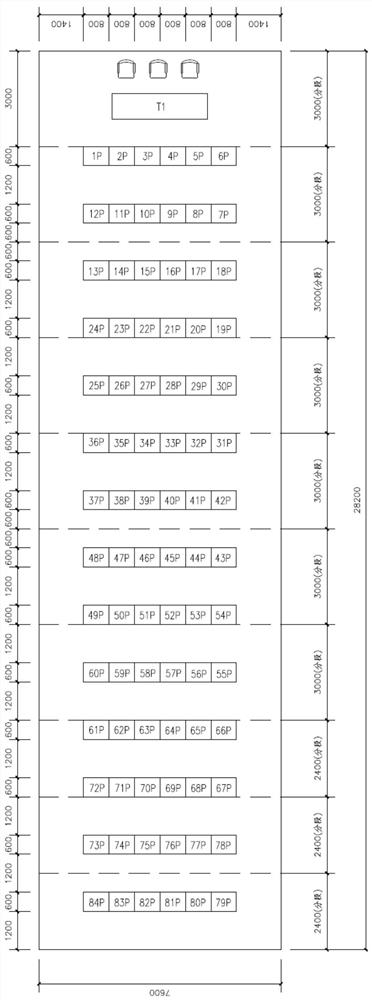

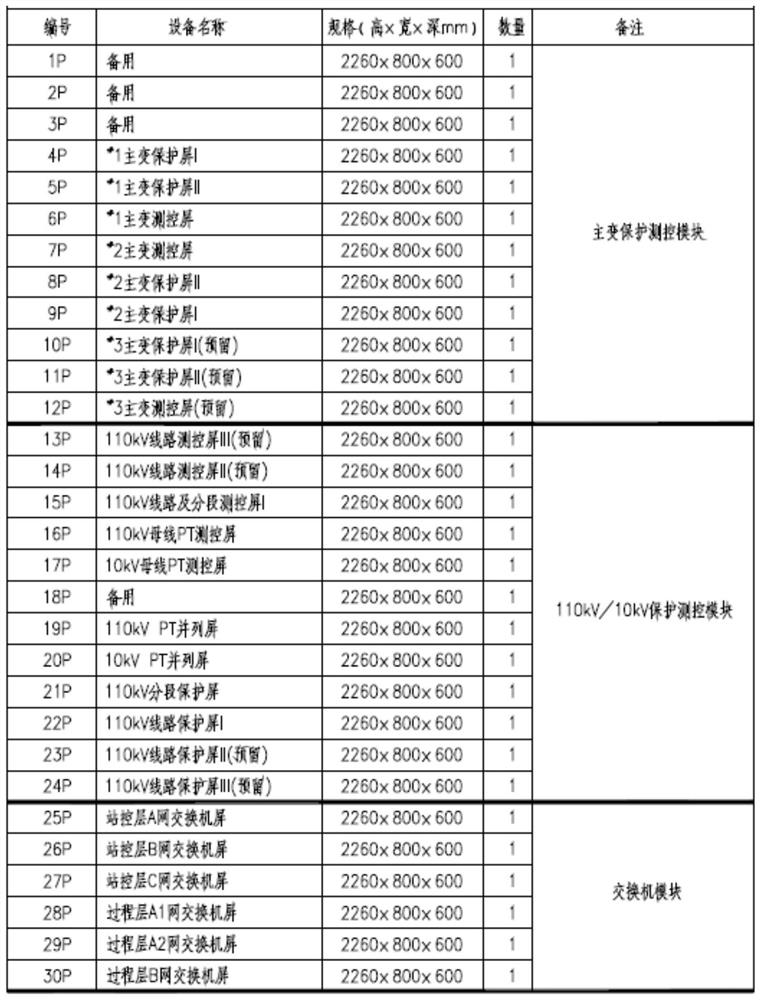

Prefabricated cabin for secondary equipment of 110-kV transformer substation

ActiveCN113241621AImprove work efficiencyShorten the construction cycleSubstation/switching arrangement detailsTransformerModularity

The invention discloses a prefabricated cabin for secondary equipment of a 110-kV transformer substation 110kV. The prefabricated cabin divides the secondary equipment into a plurality of functional modules according to functions, wherein the function modules are composed of a main console module, a protection measurement and control module, a switch module, a total station public module, a safety automation module, a metering monitoring module, a power supply module and a communication equipment module; and the cabin body of the prefabricated cabin for the secondary equipment is transversely divided into a plurality of spaces, and the functional modules are sequentially placed in the divided spaces of the prefabricated cabin. According to the prefabricated cabin for the secondary equipment of the 110-kV transformer substation, the cabin body is divided by taking intervals as units, and the secondary equipment is modularly divided according to functions, so standardized and simplified arrangement is realized, breakpoints and switching of optical cables among the secondary equipment are reduced to the greatest extent, wiring work is simplified, engineering efficiency is improved, and a station construction period is shortened.

Owner:GUANGDONG POWER GRID CO LTD

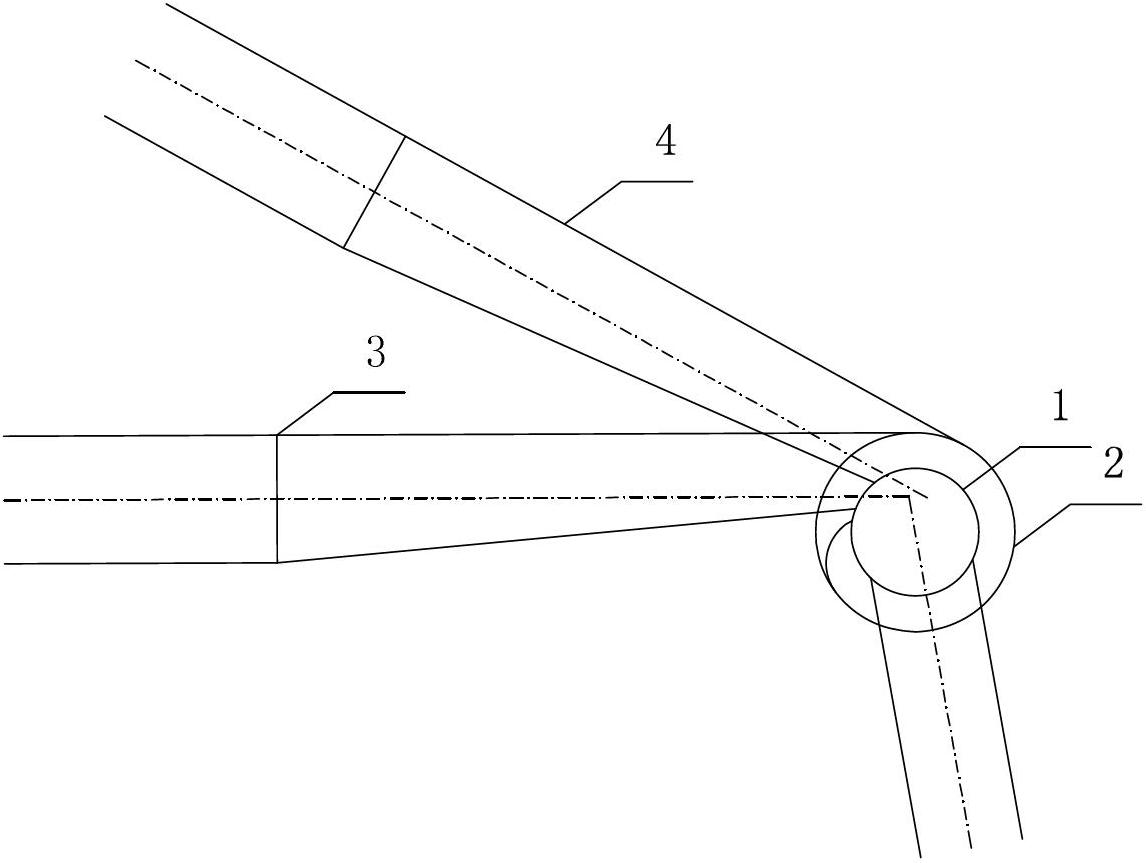

A method for dividing ship rudder area

ActiveCN109466694BShorten the construction cycleFast preparationVessel designingMarine engineeringStructural engineering

The invention discloses a method for dividing the steering area of a ship. The steering area of the ship is divided into a first part located at the lower part and a second part located at the upper part according to a set first division position line, and the second part is divided according to the second division position line. One part is divided into the first subsection and the second subsection, and the second part is divided into the third subsection and the fourth subsection. The first subsection, the second subsection, the third subsection and the fourth subsection are respectively in It is built on the tire frame, and the first segment, the second segment, the third segment and the fourth segment are assembled into the steering area in the final assembly stage. The construction of the steering area can be advanced to the segmented construction stage, the division of flat and curved areas can be optimized, the use of straight segments can be maximized, the number of flat segments can be expanded, the proportion of segments in the flat assembly line can be increased, and the occupation of segments can be reduced. The use of equipment such as tire racks, cranes, and flatbed trucks can achieve the purpose of rapid production and turnover of the steering area, reduce the construction difficulty and construction period of the subsequent dock stage, and shorten the ship construction period.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

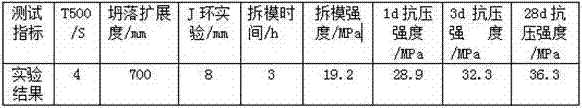

self-compacting concrete

Owner:JIAHUA SPECIAL CEMENT

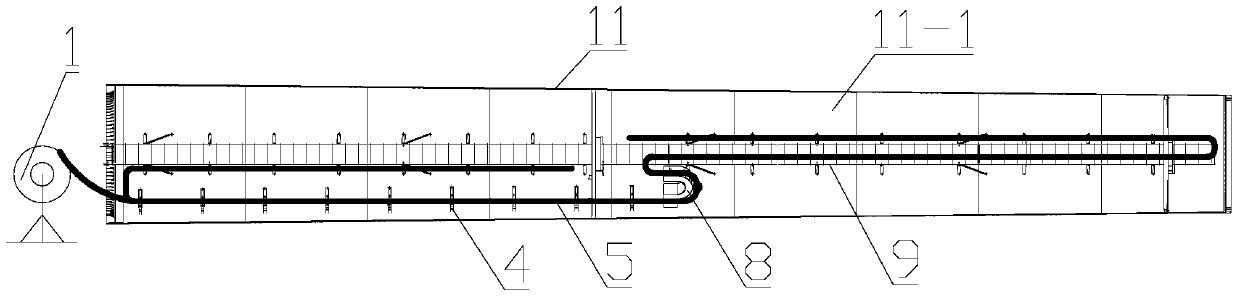

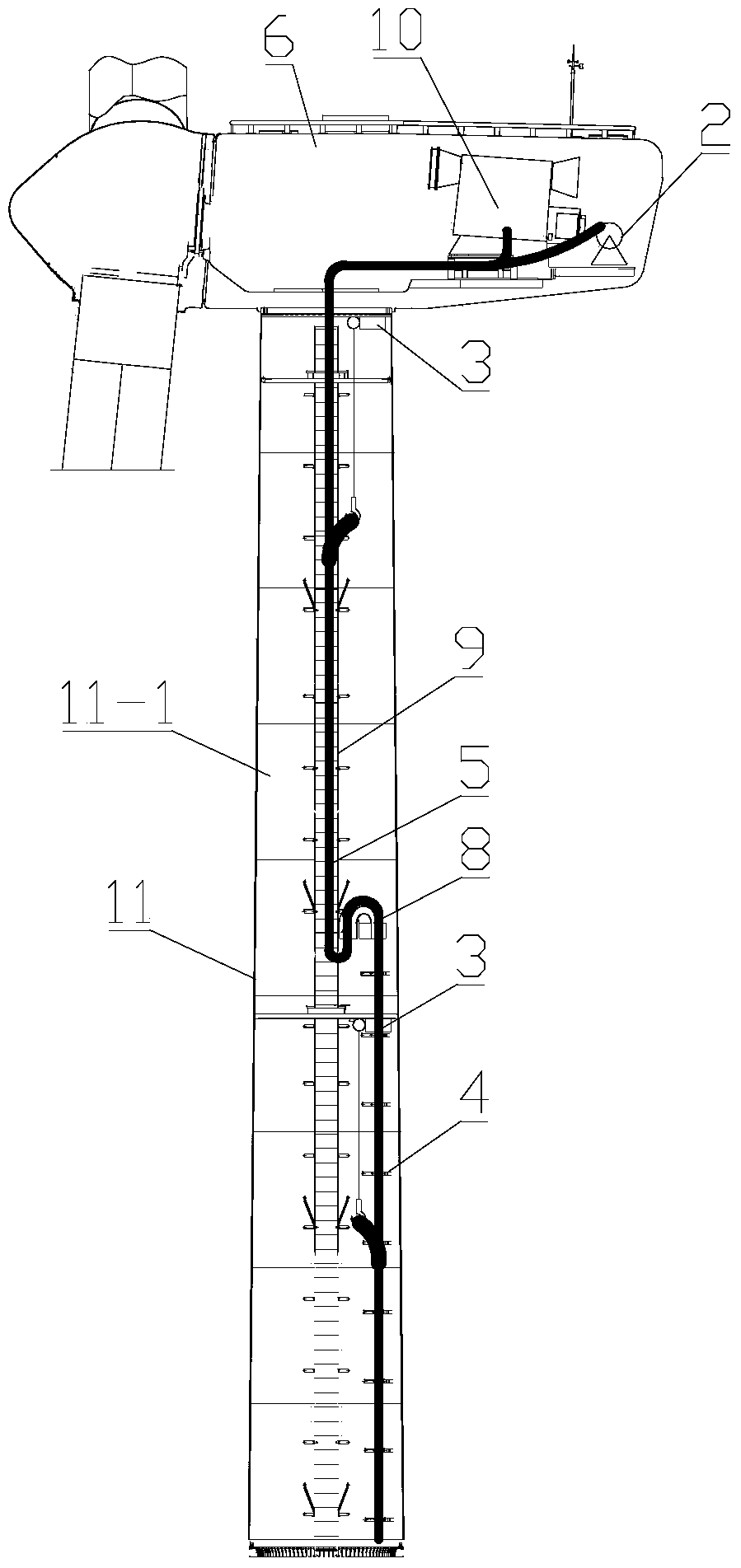

Large-scale cable laying method for wind turbines

ActiveCN105390993BThe laying process is reasonableEasy to operateApparatus for laying cablesNacelleTower

The present invention relates to a large-size cable laying method for a wind turbine generator set. The method particularly comprises the following steps: a, before lifting a wind turbine generator, arranging and fastening all large-size cables which need to be laid in an upper tower tube; b, after completing lifting the wind turbine generator, removing the large-size cables which are prearranged in the upper tower tube and are used for cable laying at the upper part of the upper tower tube, hoisting the removed large-size cables to an upper tower tube platform by using an overhead hoist, and then drawing the large-size cables to cable connection positions in a cabin by suing a traction apparatus; c, fastening the large-size cables arranged in place so as to complete the laying work of the large-size cables at the upper part of a fan tower tube; and d, removing the rest of the prearranged large-size cables, descending the removed large-size cables layer by layer by using the overhead hoist, fastening the removed large-size cables, and sequentially completing the laying and mounting work of all the large-size cables layer by layer. The large-size cable laying method for the wind turbine generator set has the beneficial effects that the laying operation process is more reasonable and is simple to operate; and the potential safety hazard in the field construction process is reduced and labor intensity of personnel is reduced.

Owner:NEW UNITED GROUP

Installation method of flash smelting furnace

ActiveCN104694765BReasonable designEasy to operateRotary drum furnacesCrucible furnacesEngineeringFlash smelting

The invention discloses an optimized flash smelting furnace mounting method which is characterized by comprising the following steps: (a), arranging a furnace body installation and preparation device of a flash smelting furnace; (b), mounting an auxiliary steel platform and a vertical longitudinal beam of the furnace body; (c) transferring various members into the furnace body; (d) mounting a furnace body bottom beam system, an upright post, a straining beam and a furnace bottom cooling system; (e), mounting a reaction tower and an uptake flue layer by layer; and (f) lifting a steel shell on the upper part of the reaction tower. The optimized flash smelting furnace mounting method disclosed by the invention has the advantages that the manufacturing steps are reasonable in design and simple in operation, the control precision is greatly improved, the construction operation cycle is greatly reduced, the engineering construction cost is reduced.

Owner:MCC5 GROUP SHANGHAI CORPORATION LIMITED

A container skid-mounted compression hydrogenation device

ActiveCN111486344BEven by forceShorten the pipe lengthVessel mounting detailsContainer filling methodsElectric machineBuffer tank

The invention discloses a container skid-mounted compression and hydrogenation device. The integrated frame of the compressor is fixedly installed in the middle part of the bottom frame of the container frame, the motor is located in the middle of the upper layer of the integrated frame of the compressor, and the first-stage compressor and the second-stage compressor are arranged side by side. It is located on the lower layer of the integrated frame of the compressor and is symmetrically arranged in front and rear relative to the motor. Both the first-stage compressor and the second-stage compressor are driven by the motor; water tanks, water pumps, air coolers and electric controls are fixed on the bottom frame behind the integrated frame of the compressor. Cabinet; on the bottom frame in front of the integrated frame of the compressor, the first heat exchanger, the second heat exchanger, the third heat exchanger, the buffer coil and the hydrogenation machine are arranged, the first heat exchanger and the second heat exchanger Distributed up and down, the third heat exchanger and the buffer coil are arranged in the left and right directions, and buffer tanks, gas pipeline systems and cooling pipeline systems are arranged in the empty positions of the container frame. The above-mentioned device has a simple and compact structure, a front-to-back balance in the overall layout, and a central center of gravity.

Owner:ZHANGJIAGANG FURUI HYDROGEN ENERGY EQUIP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com