Connecting fastener

A technology for connecting fasteners and connectors, which is applied to instruments, identification devices, etc., can solve the problems of large gaps, unevenness, and insufficient flatness of the box body, and achieve the effects of accurate positioning, uniform gaps, and high flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

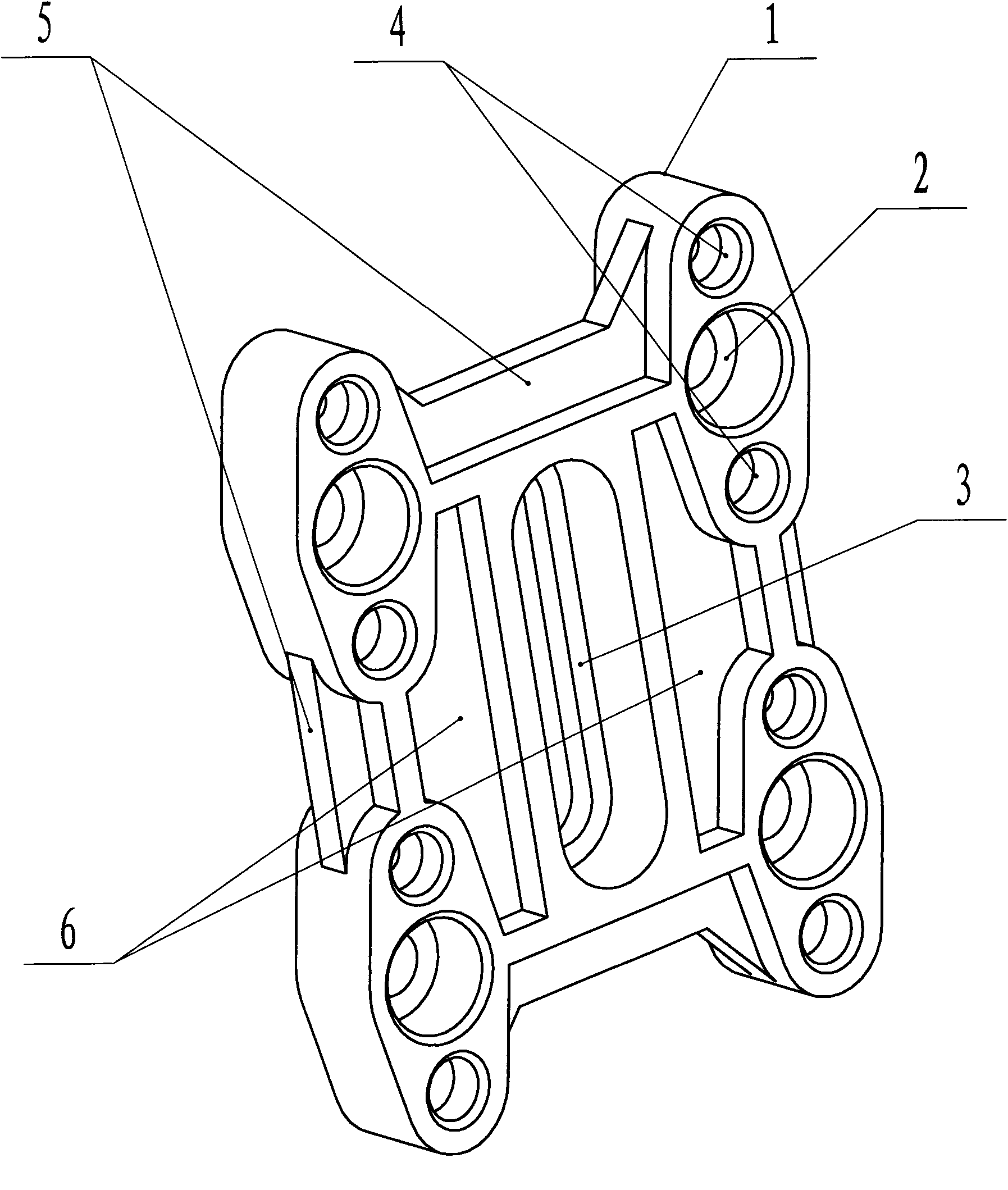

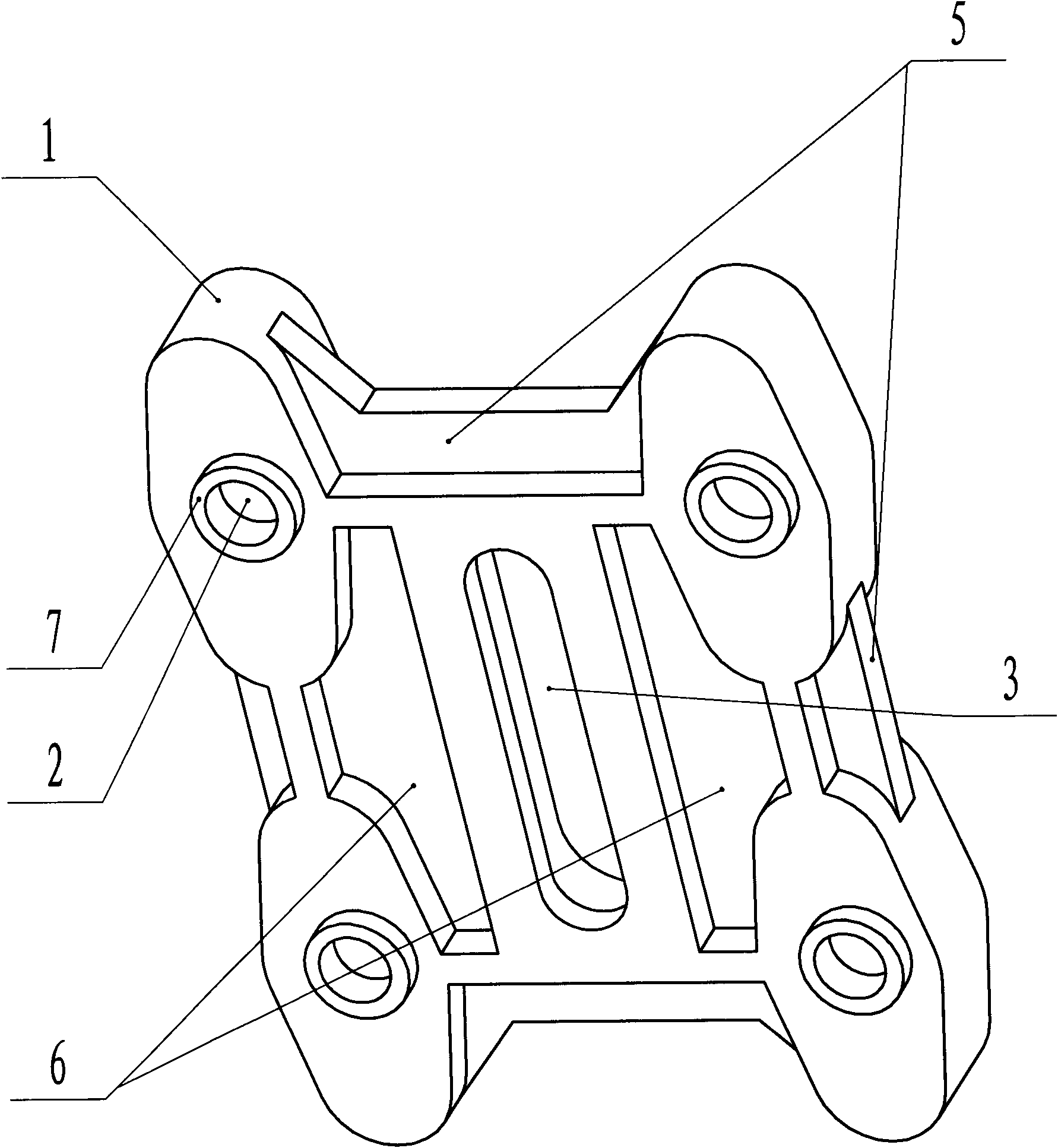

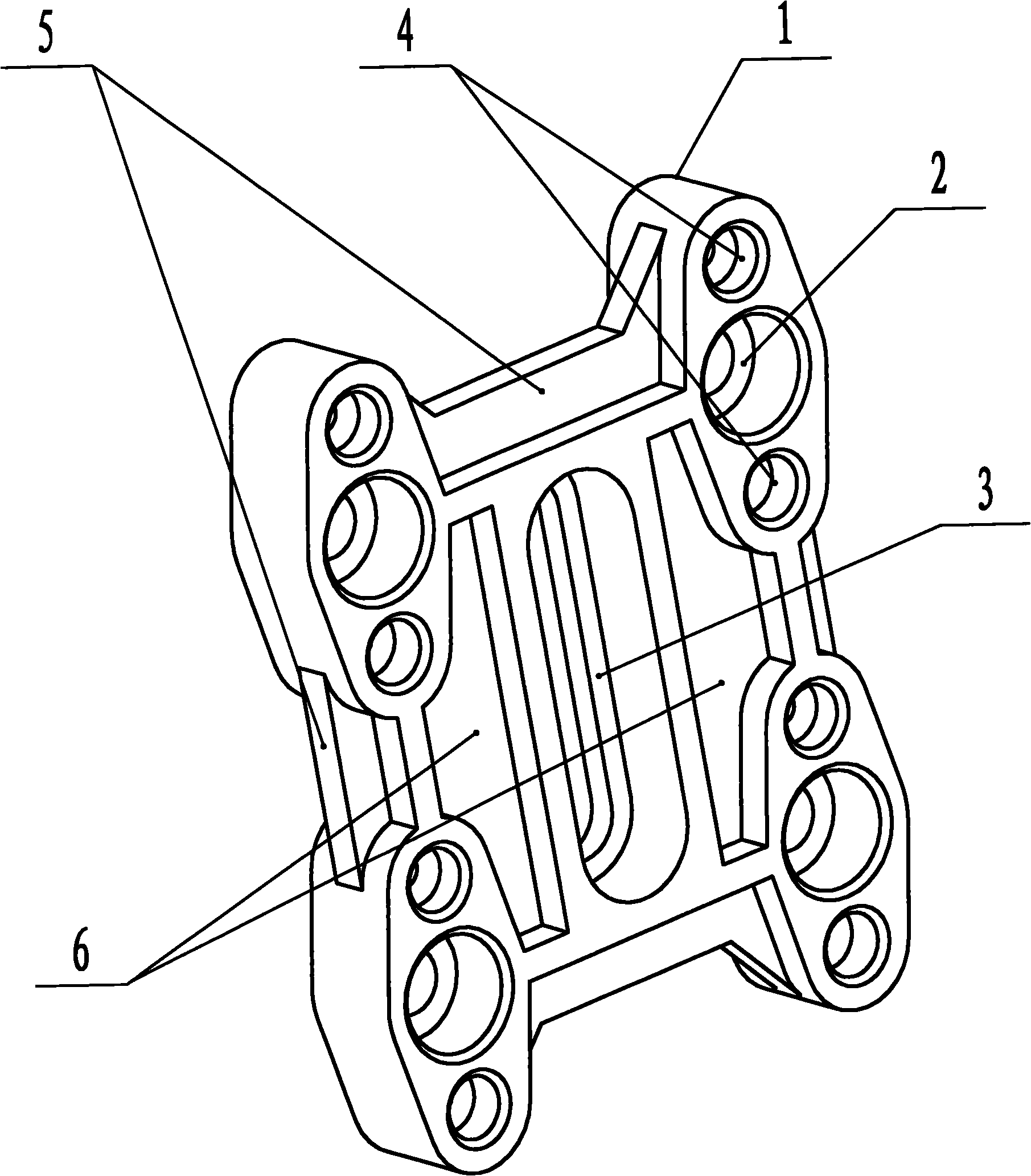

[0023] refer to figure 1 figure 2 , a connecting fastener, including a connector body 1, the connector body 1 is H-shaped, and the middle part and four corners of the connector body 1 are respectively provided with through holes.

[0024] The through holes located at the four corners of the connector body 1 are stepped through holes 2, so that the end faces of the inserted bolts or nuts do not expose the end faces of the connector body 1 during assembly.

[0025] Positioning blind holes 4 are respectively provided beside each through hole at the four corners of the connector body 1 .

[0026] Two positioning blind holes 4 are respectively provided beside each through hole at the four corners of the connector body 1 .

[0027] The stepped through hole 2 is used to fix four adjacent LED display units closely arranged in a cross shape through bolts; the positioning blind hole 4 is fitted with the positioning column set on the back of the display unit, so that the LED display u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com