Integrated pouring formwork for sound barrier foundation and box girder

A sound barrier and foundation technology, which is applied in the field of integrated pouring formwork for sound barrier foundation and box girder, can solve the problems of increased time and labor input, increased engineering cost, increased construction procedures and construction period, etc., so as to improve work efficiency and simplify The effect of construction work steps and shortening construction work cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

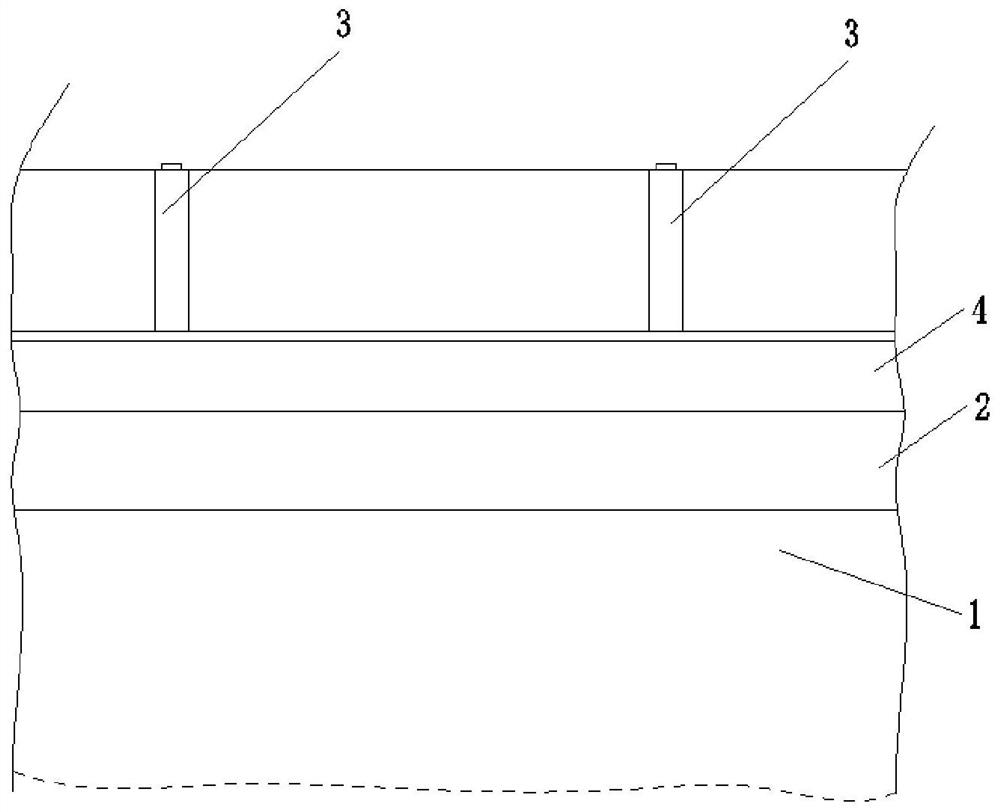

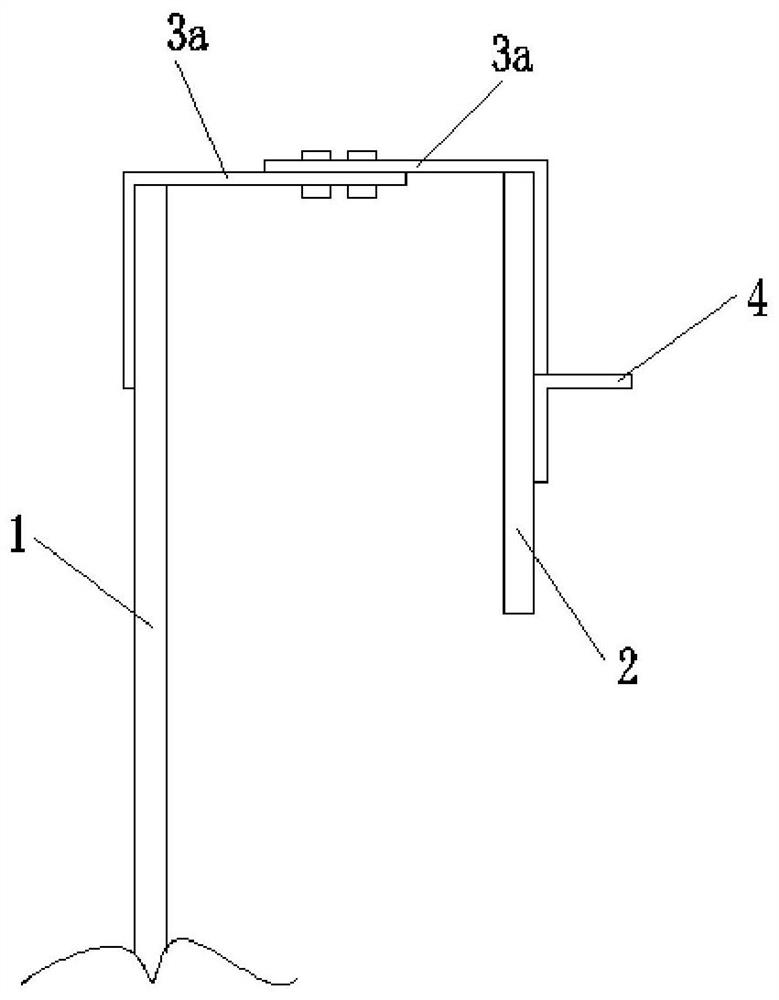

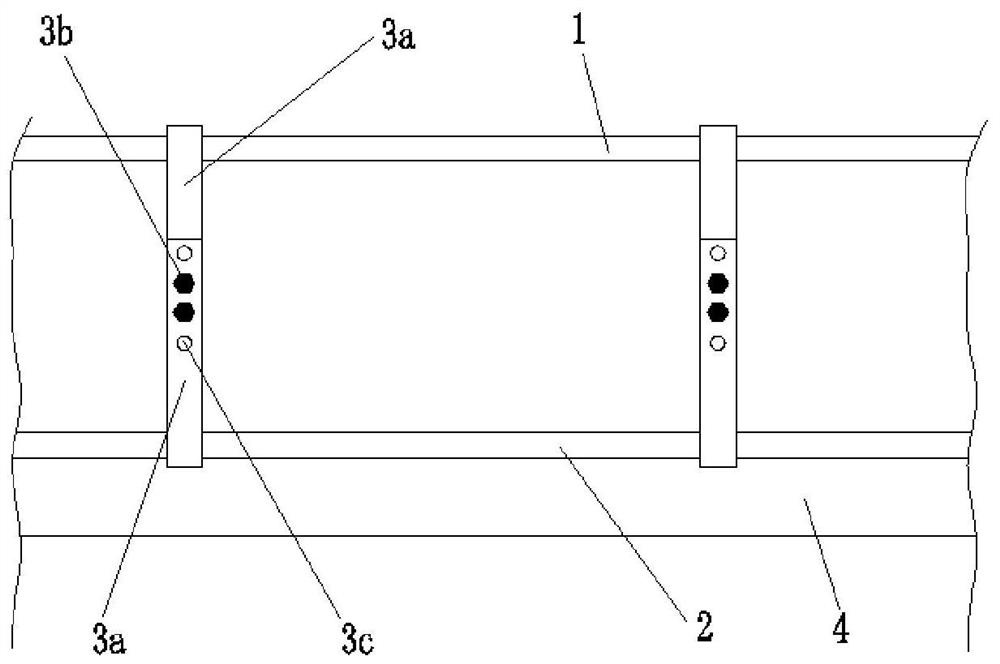

[0017] combine figure 1 — image 3 As shown, an integrated casting formwork for sound barrier foundation and box girder is mainly composed of outer formwork 1 for sound barrier foundation, inner formwork 2 for sound barrier foundation, and П-shaped connecting member 3.

[0018] The outer formwork 1 of the sound barrier foundation is formed by extending and heightening the outer formwork of the box girder as a whole. The inner formwork 2 of the sound barrier foundation adopts a rectangular steel plate with the same length as the outer formwork 1 of the sound barrier foundation. Template 1 is set in parallel. The outer formwork 1 of the sound barrier foundation and the inner formwork 2 of the sound barrier foundation are connected by several П-shaped connecting members 3 equidistantly spaced along the length direction.

[0019] The П-shaped connecting me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com