Concrete pouring formwork system of raft foundation upturning beam

A raft foundation and formwork system technology, which is applied in the direction of foundation structure engineering, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problem of easy displacement and Problems such as mold expansion can be solved to ensure the molding effect and quality, save labor costs, and stabilize the formwork system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

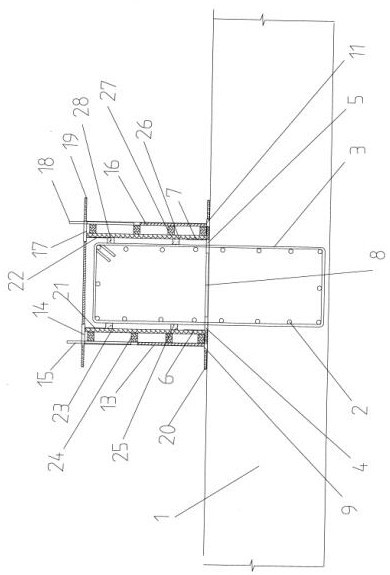

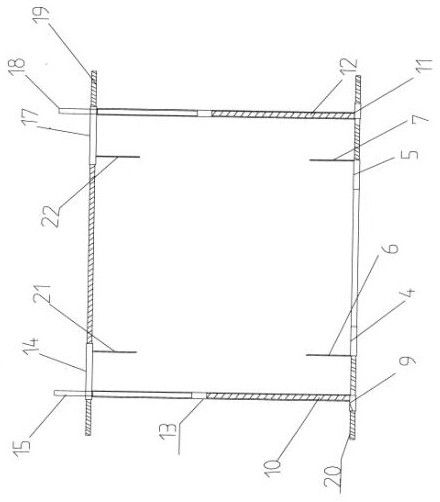

[0021] The present invention is described in detail below in conjunction with accompanying drawing:

[0022]A formwork system for concrete pouring of turned beams on raft foundations, including a raft foundation steel skeleton 1, on which the main reinforcement 2 of the turned beam and the stirrup 3 of the turned beam are arranged, and the precast valve plate On the upturning beam stirrup 3 at the connection with the precast upturning beam, along the left and right horizontal directions, the left inner piercing sleeve 4 of the lower tension bolt and the right inner piercing sleeve 5 of the lower tension bolt are respectively welded, The central axis of the left inner threading sleeve 4 of the lower pair of pull bolts coincides with the central axis of the right inner threading sleeve 5 of the lower pair of pull bolts. On the upper side, there is a lower limit steel plate 6 on the inner side of the left formwork connected by welding, and on the outer wall of the right end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com