Spoon-shaped steel formwork for junction part of elliptic cylinder and straight wall, formwork system and construction method

A technology of steel formwork and elliptical column, which is applied in the field of building construction, can solve the problems of poor forming effect and can not well guarantee the mechanical performance of the structure, and achieves the effect of speeding up the construction speed, good forming effect, and avoiding mold expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

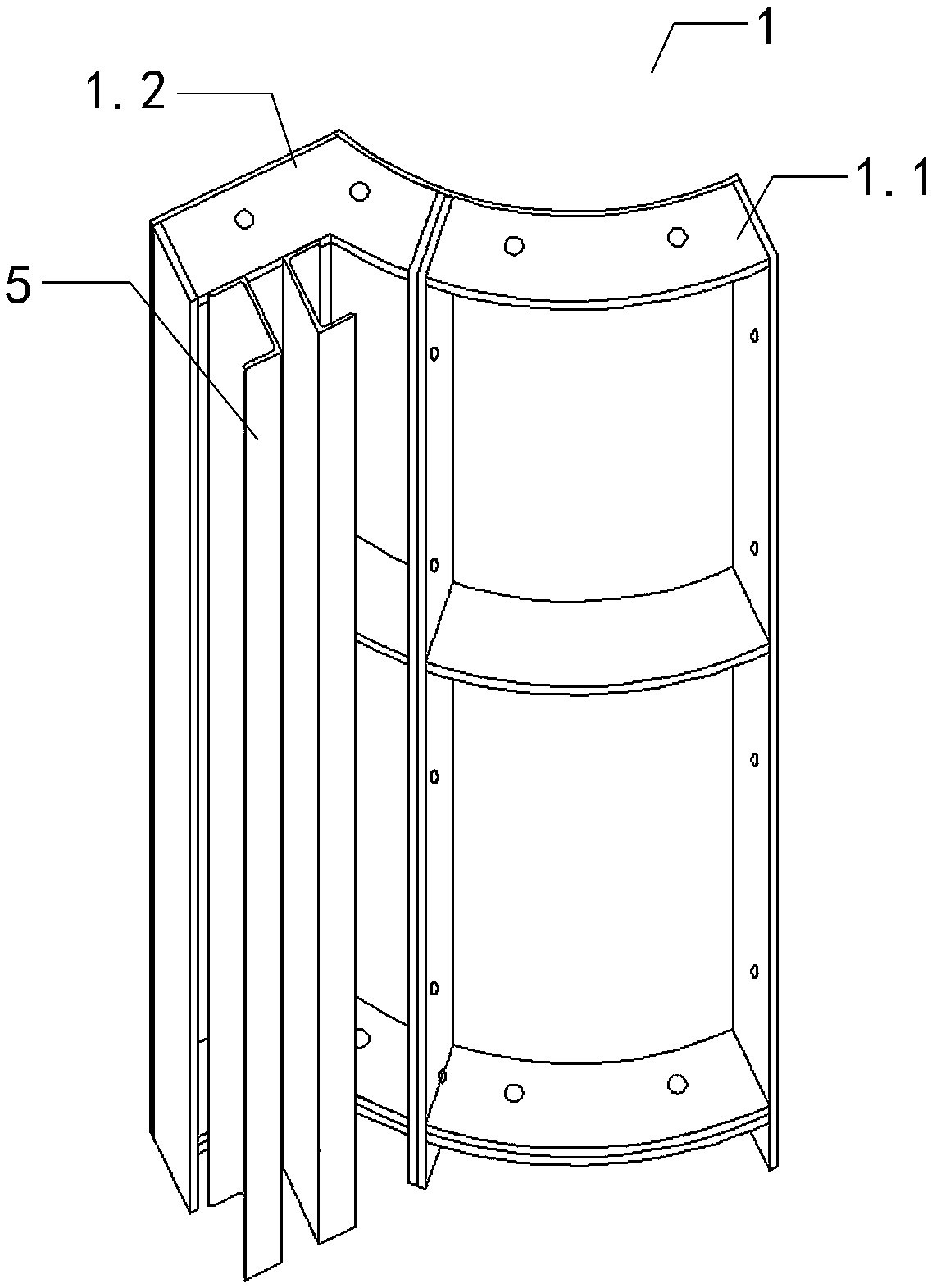

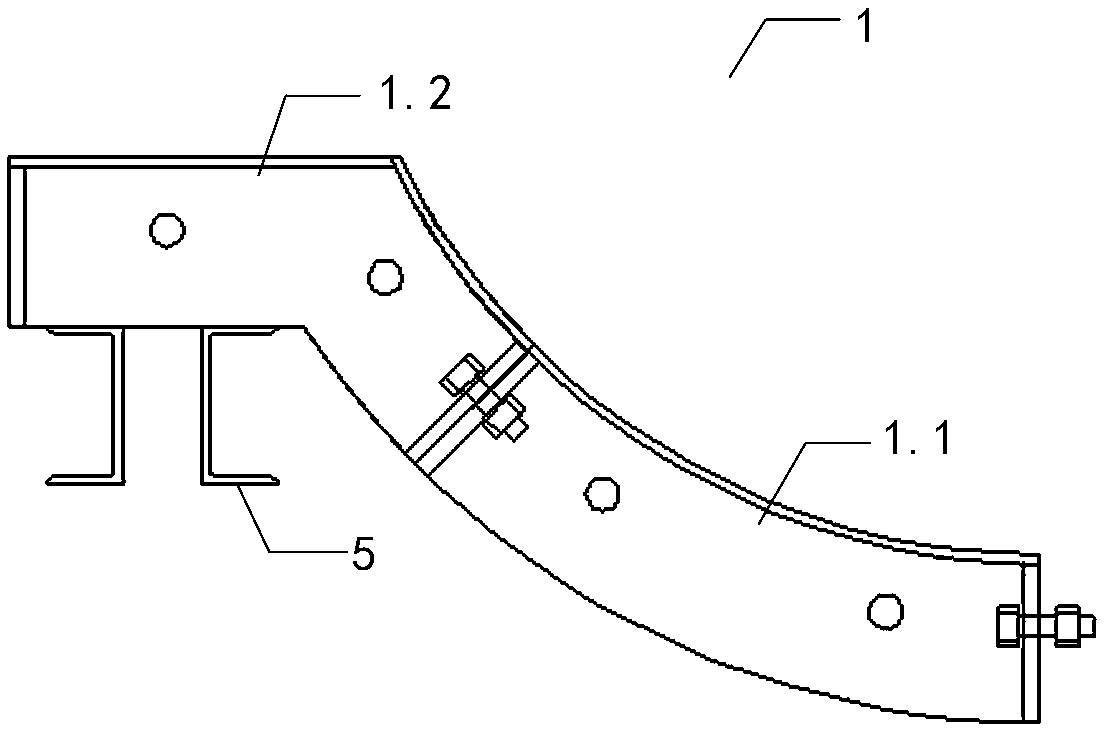

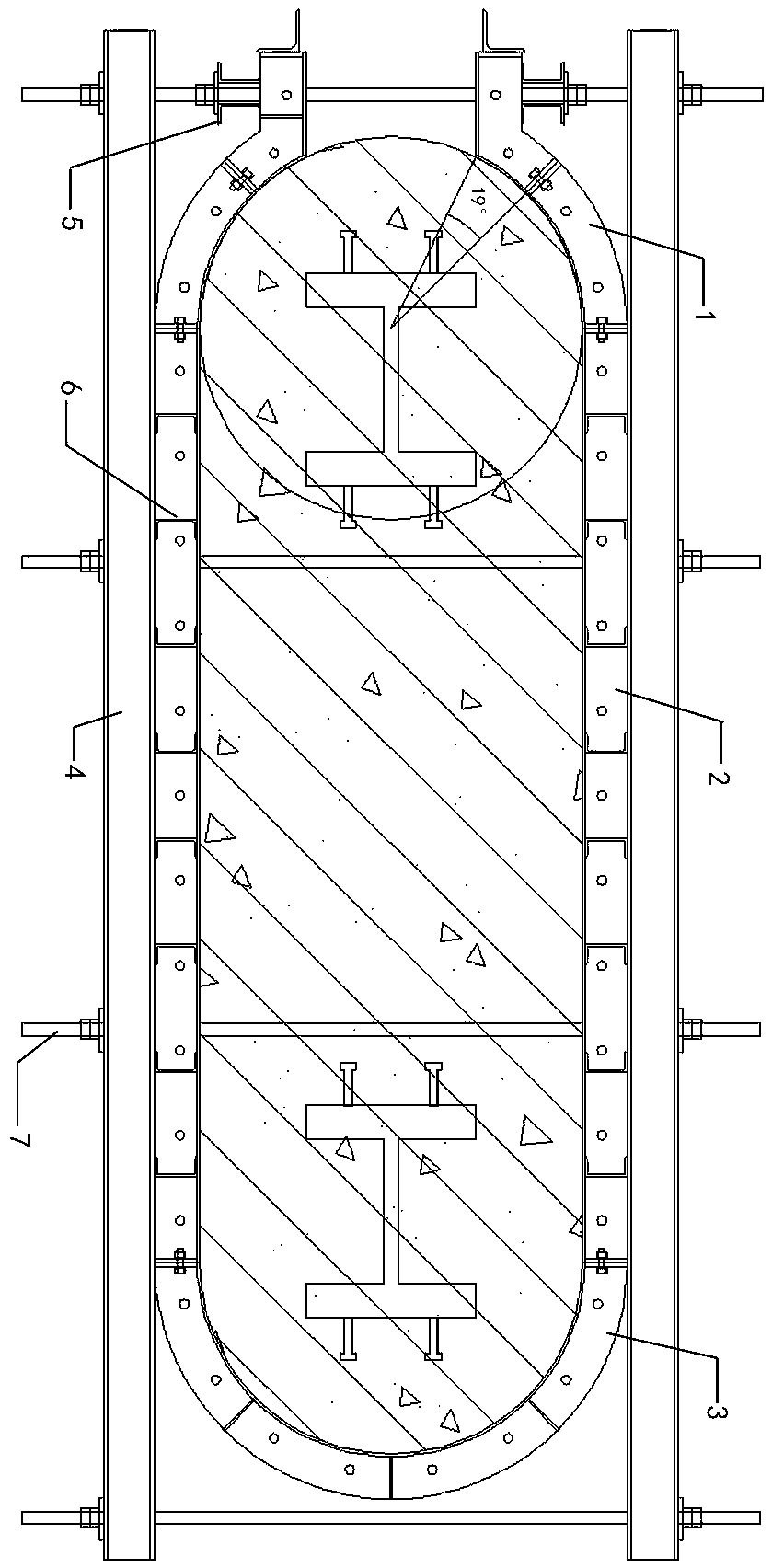

[0054] Examples see figure 1 and figure 2 As shown, the spoon-shaped steel formwork and formwork system at the junction of the elliptical column and the straight wall

[0055] and the construction method, the spoon-shaped steel formwork includes a circular arc portion 1.1 and a transfer portion 1.2; the circular arc portion is formed by sequentially connecting multiple circular arc segments up and down, and a single segment of the circular arc segment includes an arc-shaped plate , the first upper connecting plate horizontally connected to the upper edge of one side of the arc-shaped plate, the first lower connecting plate horizontally connected to the lower edge of one side of the arc-shaped plate and the first lower connecting plate vertically connected to the two sides of the arc-shaped plate One side connection plate; the middle part between the two first side connection plates is connected with a horizontal first reinforcing rib 5; the first upper connection plate, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com