High salinity wastewater electrolytic oxidation treatment device

An electrolytic oxidation and treatment device technology, applied in water/sewage treatment, water/sludge/sewage treatment, electrode shape/type, etc., can solve the problem that the suspension parts affect the water inflow and operation, the parallel plate treatment effect is low, and it is not suitable for High-salt wastewater treatment and other issues, to achieve good prospects for use, facilitate disassembly and assembly, and improve biochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

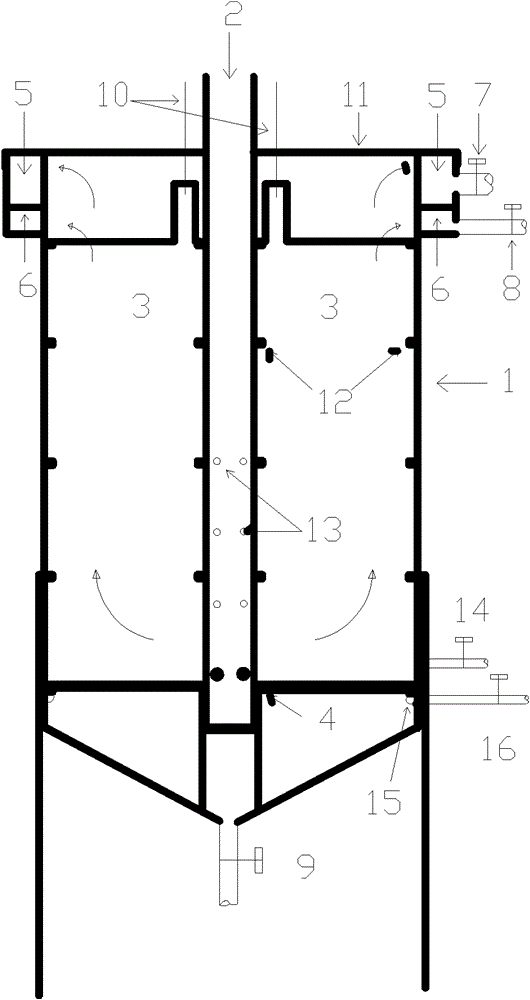

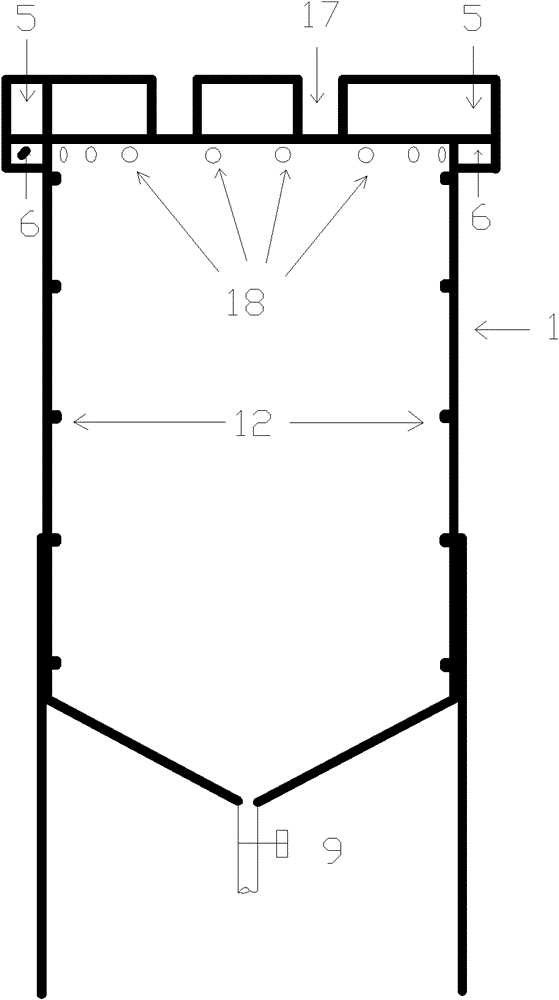

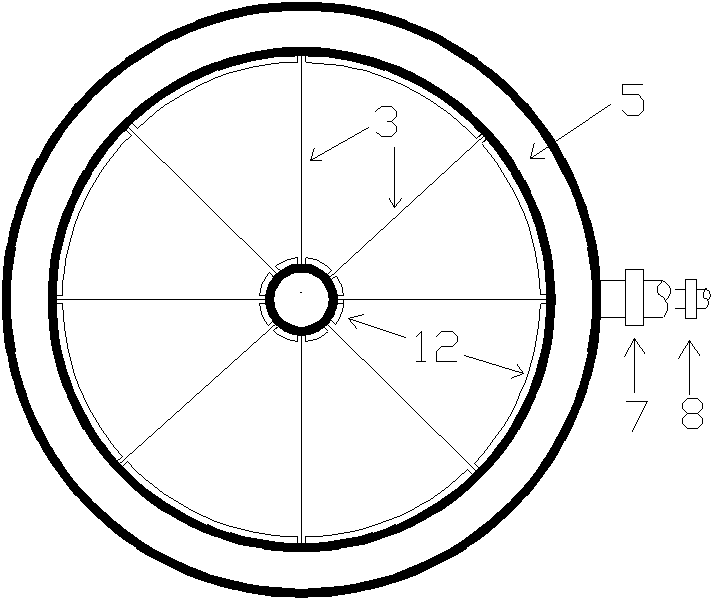

[0023] Such as figure 1 As shown, the present invention is a device for electrolytic oxidation treatment of high-salt wastewater. First, the electrolytic column 1 (such as figure 2 shown) on the base of the device, and then put the center support 4 (such as Figure 4 shown) into the electrolytic column (1), and the cross support ring (21) is just placed on the pole plate fixing ring (12) on the inner wall of the electrolytic column. Then insert the water inlet pipe (2) into the water pipe socket (19) of the center support, turn the water pipe to adjust the position, and make the small slot on the pole plate fixing ring (12) on the outer wall of the water pipe fix with the pole plate on the inner wall of the electrolytic column The position of the small slot on the circle corresponds to the installation of the electrode plate. Then insert the electrode plate (3) into the small slot of the plate fixing ring (12) on the outer wall of the water pipe and the electrode plate fixi...

Embodiment 2

[0027] Such as figure 1 As shown, the present invention is a device for electrolytic oxidation treatment of high-salt wastewater. First, the electrolytic column (1) (such as figure 2 shown) fixed on the base of the device, and then the center support (4) (such as Figure 4 shown) into the electrolytic column (1), and the cross support ring (21) is just placed on the pole plate fixing ring (12) on the inner wall of the electrolytic column. Then insert the water inlet pipe (2) into the water pipe socket (19) of the center support, turn the water pipe to adjust the position, and make the small slot on the pole plate fixing ring (12) on the outer wall of the water pipe fix with the pole plate on the inner wall of the electrolytic column The position of the small slot on the circle corresponds to the installation of the electrode plate. Then insert the electrode plate (3) into the small slot of the plate fixing ring (12) on the outer wall of the water pipe and the electrode plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com