Construction process of foam concrete light roadbed above subway tunnel

A foamed concrete and construction technology technology, applied in the direction of roads, roads, buildings, etc., can solve the problems of running subway shield tunnels, such as interval loss, high risk, and strict construction control requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

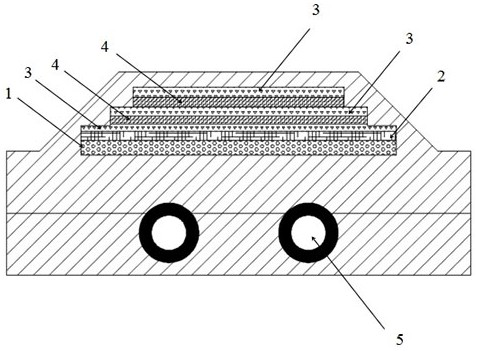

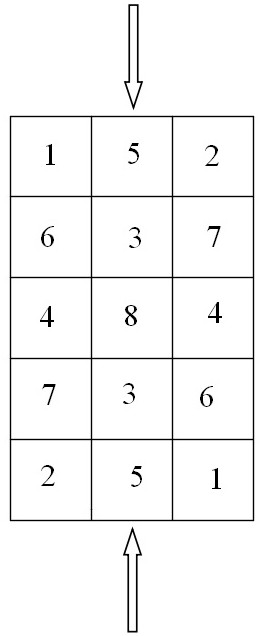

[0029] refer to Figure 1-2 Shown, a kind of foam concrete lightweight subgrade construction technology above the subway tunnel comprises the following steps;

[0030] S1: Excavate the construction subgrade, and preset the filling area; the excavation depth of the filling area is determined by the actual road conditions of the subgrade, and is obtained through the simulation calculation of the research institute;

[0031] S2: Clean and level the base of the filling area to ensure that the base is flat and free of water and debris at the bottom; before construction of the lightweight foam concrete subgrade, the foundation pit must be smooth and free of water, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com