self-compacting concrete

A self-compacting concrete and retarder technology, which is applied in the field of building materials, can solve the problems of dry shrinkage, low strength, and honeycomb pockmarks, etc., and achieve the effects of reducing dosage, improving surface compactness, high flatness and gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

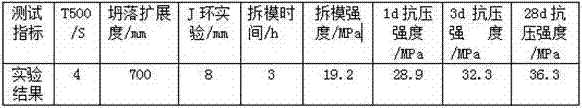

[0033] A self-compacting concrete containing the following weights of raw materials per cubic meter of concrete, as shown in the table below:

[0034]

[0035] Explanation: T500 is used to test the segregation resistance, stability and relative viscosity of cement, and the J ring test is used to test the passing ability and anti-blocking ability of cement.

[0036] In the present embodiment, the specific surface area of sulfoaluminate cement is 358m 2 / kg, 80μm square hole sieve remaining 8%; initial setting time 30min, final setting time 45min; water demand 128ml; 3d flexural strength 7.0MPa, compressive strength 42.8MPa, 28d flexural strength 7.6MPa, compressive strength 51MPa .

[0037] In this example, the polycarboxylate superplasticizer has a solid content of 28% and a water reducing rate of 29%. After the polycarboxylate superplasticizer is added, the air content of the concrete is 4.5%.

[0038] In the present embodiment, the mud content of the sand in the washi...

Embodiment 2

[0044] A self-compacting concrete containing the following weights of raw materials per cubic meter of concrete, as shown in the table below:

[0045]

[0046] In this embodiment, the setting retarder is sodium citrate.

[0047] In this embodiment, the specific surface area of sulphoaluminate cement is 375m 2 / kg, 80μm square hole sieve remaining 6%; initial setting time 28min, final setting time 40min; water demand 140ml; 3d flexural strength 7.8MPa, compressive strength 46MPa, 28d flexural strength 8.2MPa, compressive strength 53MPa.

[0048] In this example, the polycarboxylate superplasticizer has a solid content of 30% and a water reducing rate of 27%. After the polycarboxylate superplasticizer is added, the air content of the concrete is 6.5%.

[0049] In this embodiment, the mud content of the sand in the water washing is 0.4%, the fineness modulus is 2.97, and the gradation distribution: the remainder of the 4.75mm standard sieve accounts for 5%, the remainder of...

Embodiment 3

[0055] A self-compacting concrete containing the following weights of raw materials per cubic meter of concrete, as shown in the table below:

[0056]

[0057] In this embodiment, the retarder is sucrose.

[0058] In this embodiment, the specific surface area of sulphoaluminate cement is 365m 2 / kg, 80μm square hole sieve residue 6.5%; initial setting time 30min, final setting time 41min; water demand 130ml; 3d flexural strength 7.7MPa, compressive strength 44MPa, 28d flexural strength 8.0MPa, compressive strength 53MPa.

[0059] In this example, the polycarboxylate superplasticizer has a solid content of 30% and a water reducing rate of 27%. After the polycarboxylate superplasticizer is added, the air content of the concrete is 6.0%.

[0060] In this example, the mud content of the sand in water washing is 0.3%, the fineness modulus is 3.0, and the gradation distribution: 4.75mm standard sieve accounts for 6%, 2.36mm standard sieve accounts for 20%, and 1.18mm standard ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com