Container skid-type compression hydrogenation device for hydrogen dispenser

A hydrogen refueling device and container technology, which is applied in the field of hydrogen refueling stations, can solve problems such as low refueling efficiency, complex structure, and long station construction period, and achieve the effects of improving refueling efficiency, reducing costs, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical scheme of the present invention will be further described in detail below in conjunction with the drawings and preferred embodiments.

[0032] Such as Figure 5 As shown, a container skid-type compression hydrogenation device for a hydrogen refueling machine according to the present invention includes: a container frame 100. The container frame 100 is composed of a top frame 101, a bottom frame 102 and a four-sided side frame (four-sided side frame Including: the front side frame 103, the rear side frame 104, the left side frame 105 and the right side frame 106) constitute a rectangular parallelepiped frame structure.

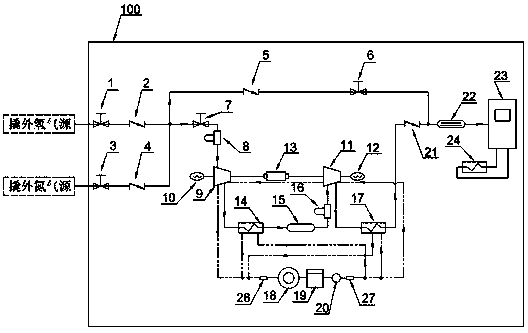

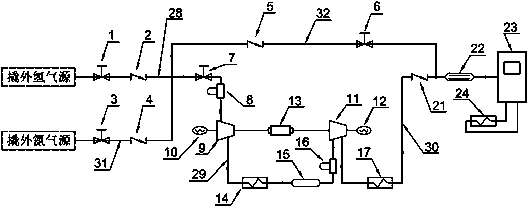

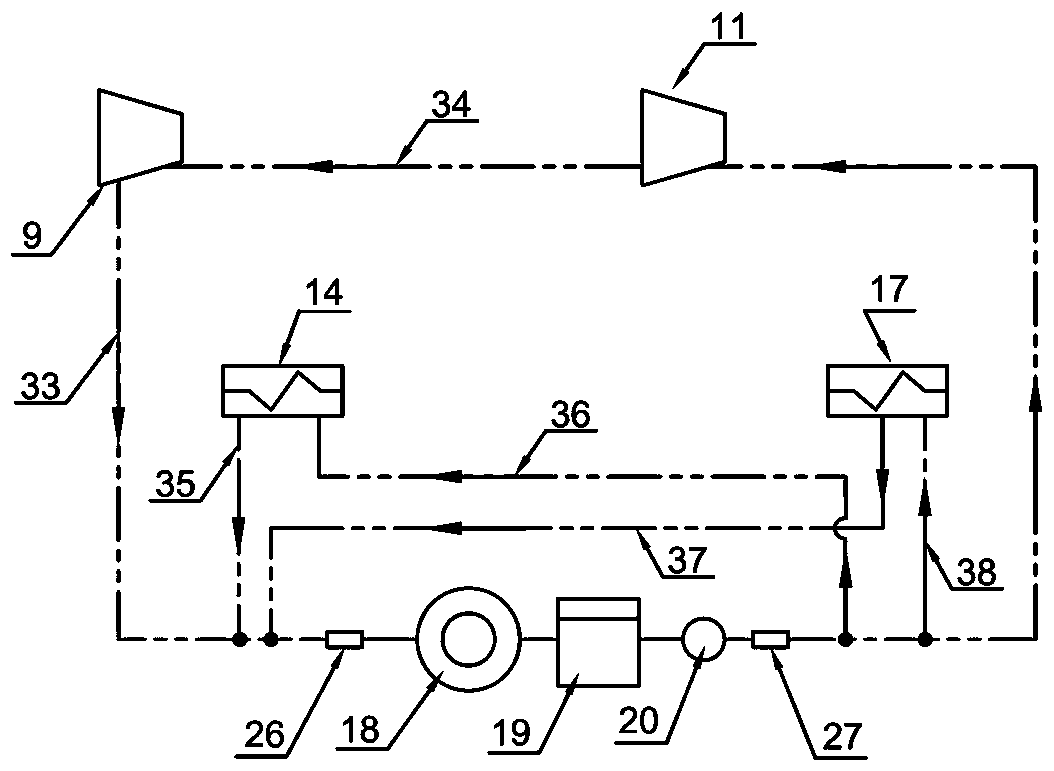

[0033] See figure 1 As shown, a compressor integrated frame 25, a first heat exchanger 14, a second heat exchanger 17, a buffer tank 15, an air cooler 18, a water tank 19, a water pump 20 and a hydrogen refueling machine 23 are fixedly installed in the container frame 100. The gas outlet of the hydrogenation machine 23 is connected with a hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com