Leveling and troweling and film covering maintenance integrated equipment

A film covering and equipment technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of failure to take, damage and other problems, and achieve the effects of ensuring the quality of concrete, saving labor costs, and shortening the construction cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

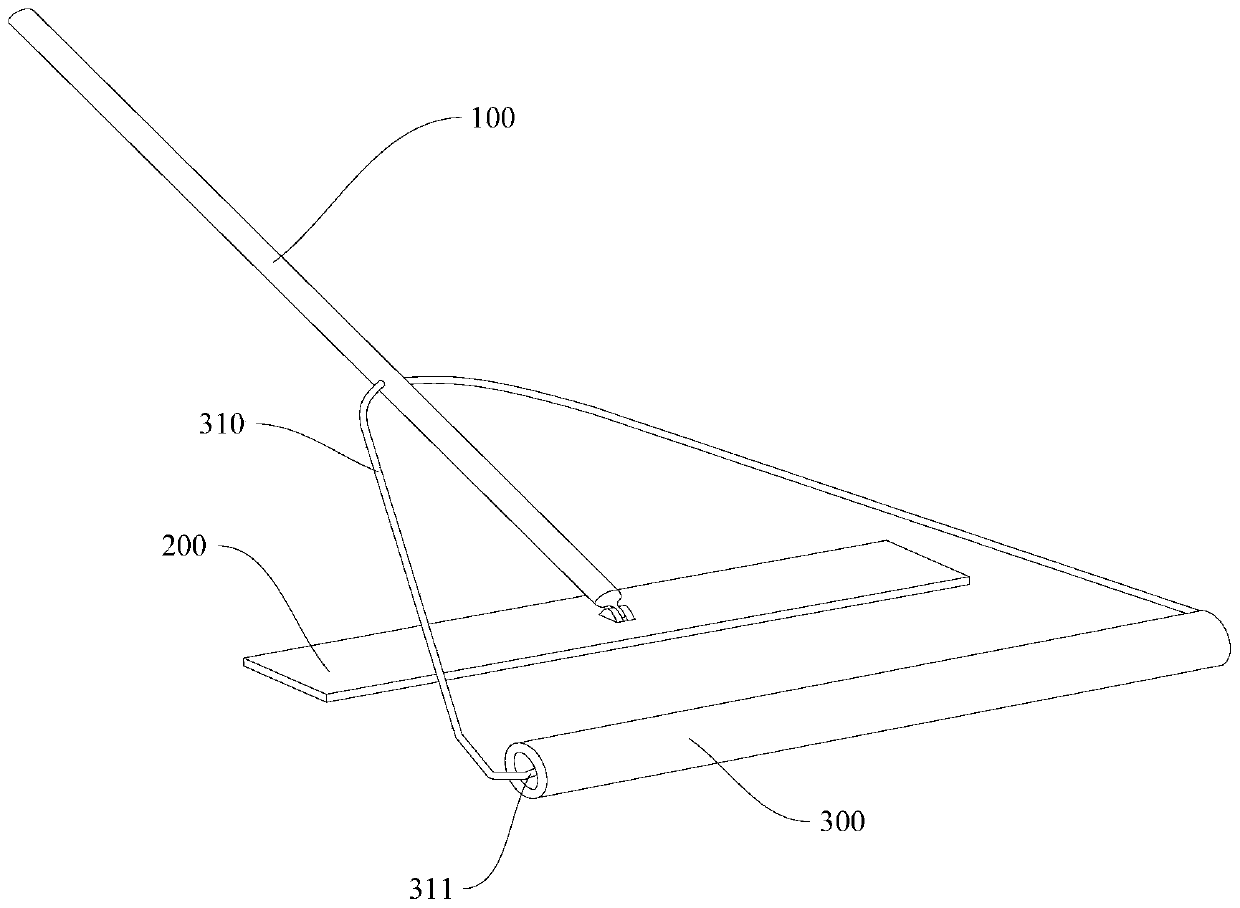

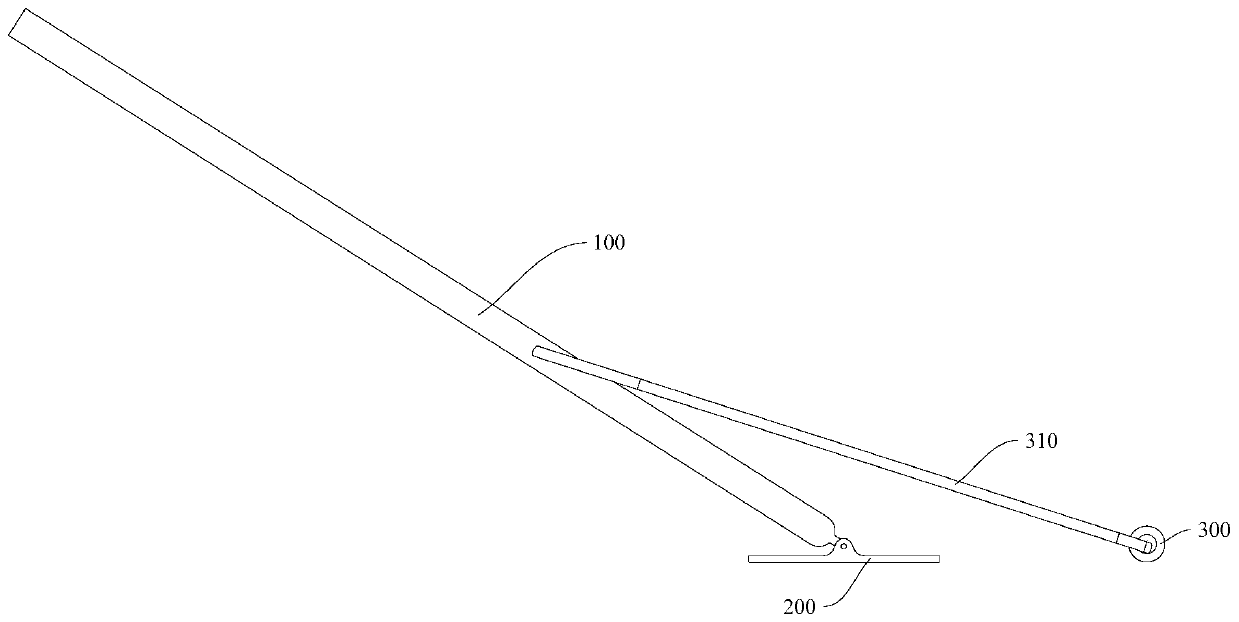

[0030] This embodiment provides an integrated equipment for leveling, troweling and film covering maintenance, please refer to figure 1 and figure 2 , this integrated equipment for leveling, troweling and film covering maintenance includes a handle bar 100, a leveling and troweling board 200, and a film covering roller 300, wherein the film covering roller 300 is wound with a film.

[0031] The handle 100 includes an installation end, and the leveling and troweling board 200 is hingedly arranged at the installation end; the leveling and troweling board 200 has a working surface for troweling;

[0032] The grip bar 100 is provided with a roller clamping part, and the roller clamping part extends from the middle of the handle bar 100 to the direction of the working surface; the film covering roller 300 is installed at the end of the roller clamping part, and the film covering roller 300 has the same structure as the working surface. face coverage.

[0033] The working surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com