Installation method of flash smelting furnace

A technology for flash smelting furnaces and installation methods, applied in furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of small furnace installation space, difficult construction and high technical requirements, small furnace construction space, etc. The effect of cycle reduction, reasonable design of manufacturing steps, and reduction of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The optimization flash smelting furnace installation method of the present invention comprises the following steps:

[0048] a. Set up the flash smelting furnace body installation preparation device, including the following steps:

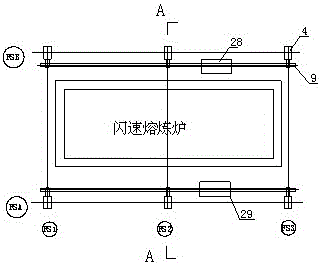

[0049] see now Figure 9 and 10 , Figure 9 For the flash smelting furnace of the embodiment of the present invention, a 9.7m beam bottom lifting measure transportation layout diagram is installed, Figure 10 for Figure 9 A-A sectional view in .

[0050](1) Set up an electric hoist track beam at an elevation of ▽±9.7m above the main smelting workshop (line 14-15) and install two 10t electric hoists. The electric hoist beam is made of I-beam 360*140*14mm, The track beam adopts [160*65*8.5mm butt-welded square pipes, which are respectively welded and hung with the structural beams of the workshop;

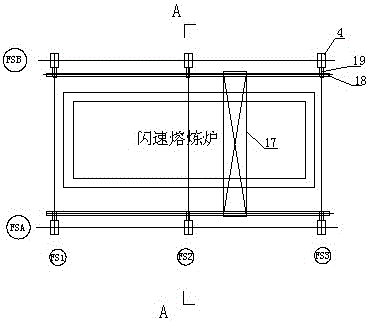

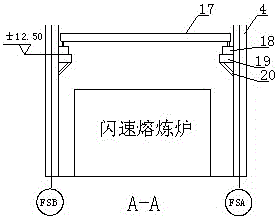

[0051] see now figure 1 and 2 , figure 1 It is the furnace top layout diagram of the flash smelting furnace furnace body and the sedimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com