Large-scale cable laying method for wind turbines

A technology for wind turbines and large cables, applied in cable laying equipment and other directions, can solve the problems of low work efficiency, high labor intensity, low work efficiency, etc., and achieve the effect of reducing labor intensity, reducing the number of workers, and reducing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

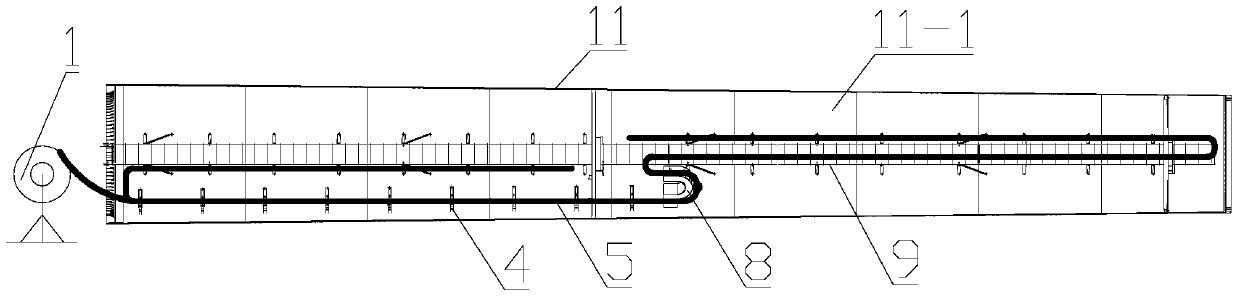

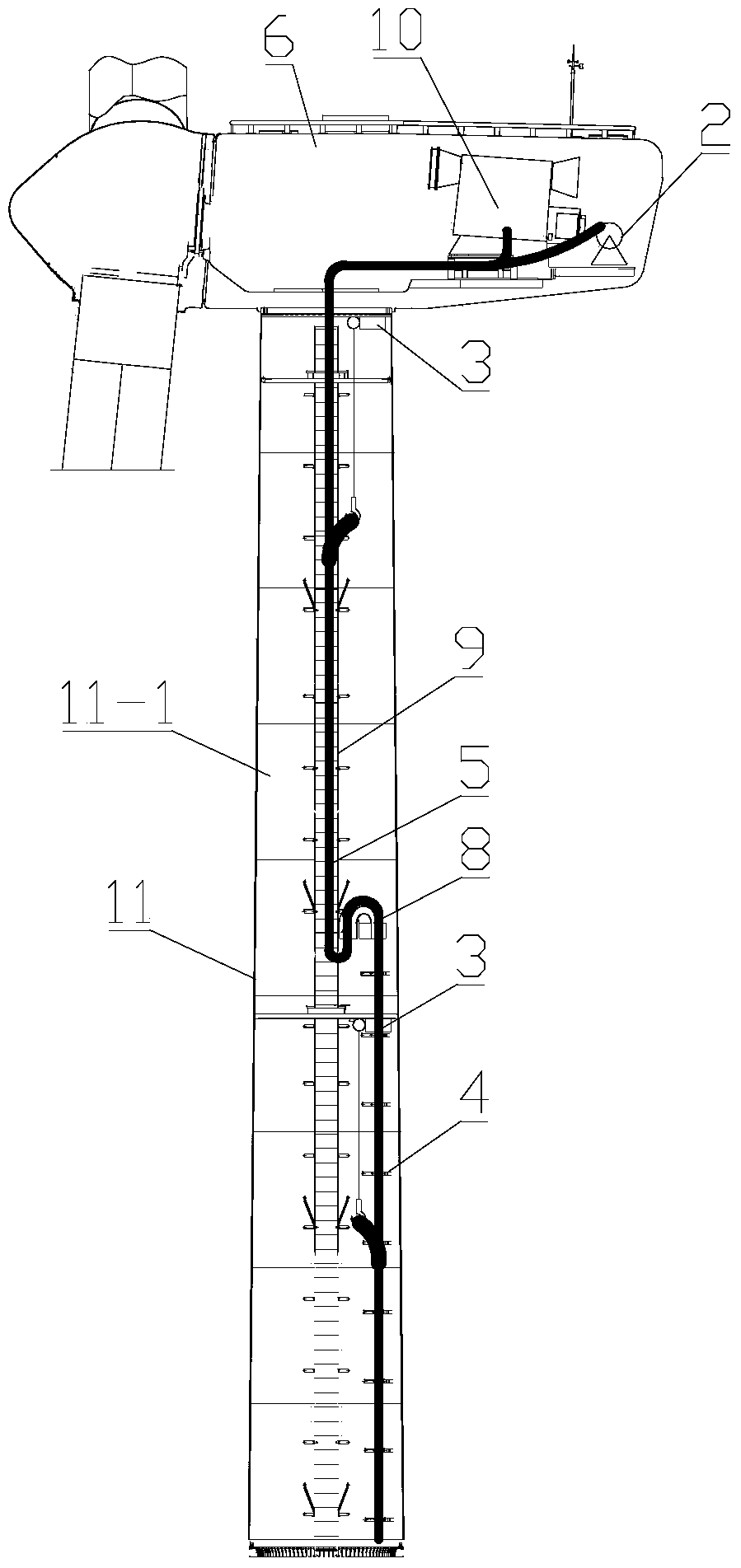

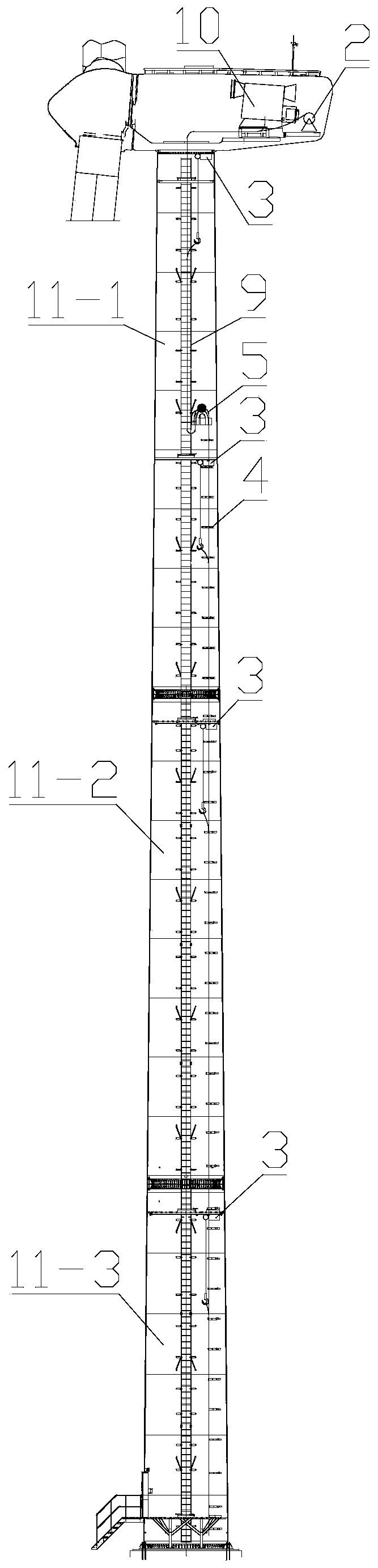

[0020] Such as figure 1 , 2 As shown in and 3, a large-scale cable laying method for a wind power generating set, the large-scale cable laying method requires the use of a pay-off device 1, a traction device 2, a hoisting device 3 and a cable clamp 4. Wherein the pay-off device 1 is used for releasing the coiled large-sized cable 5 . The pulling device 2 is fixed in the nacelle 6 and can pull the large cables 5 to the installation position from bottom to top. The hoisting device 3 is fixed on the lower part of the tower platform 7 of the fan tower according to hoisting requirements, and is used for hoisting large cables 5 . The cable clamp 4 is installed on the tower wall of the fan tower, which can effectively fix large cables 5 . The fan tower 11 includes an upper tower 11-1, a middle tower 11-2 and a lower tower 11-3, all of which have a tower platform 7 inside.

[0021] The laying method has the following steps:

[0022] a) Pre-arrangement of large-scale cables 5 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com