A suction structure of a refrigeration compressor

A refrigeration compressor and compressor technology, which is applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc. Refrigeration performance limitation and other issues, to achieve the effect of improving refrigeration performance, stabilizing suction booster effect, and improving energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

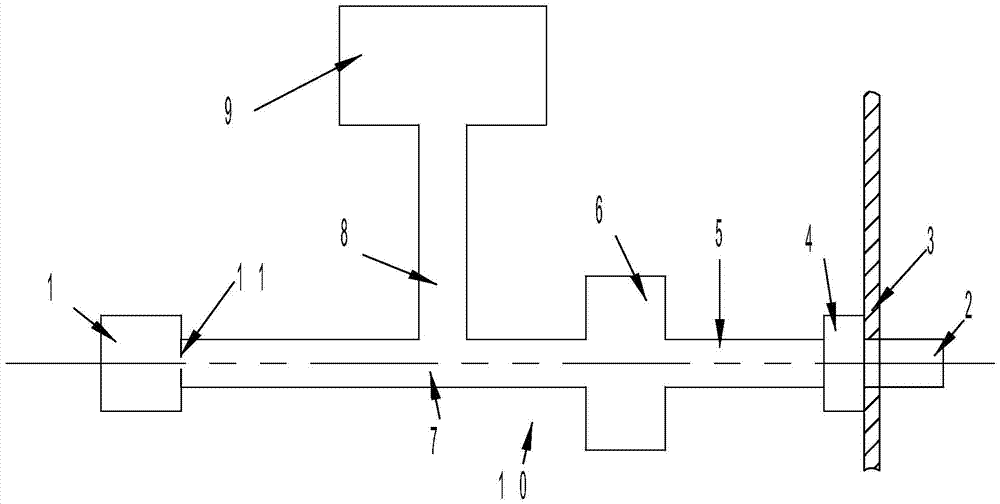

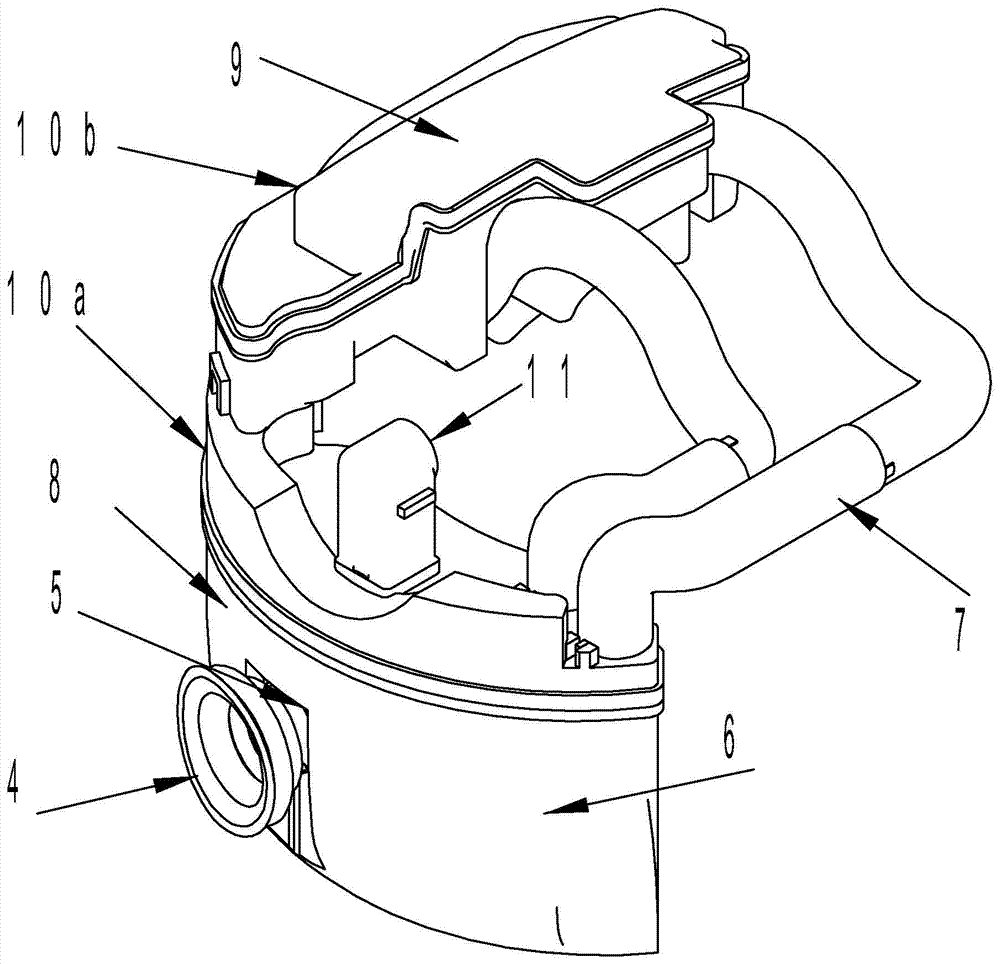

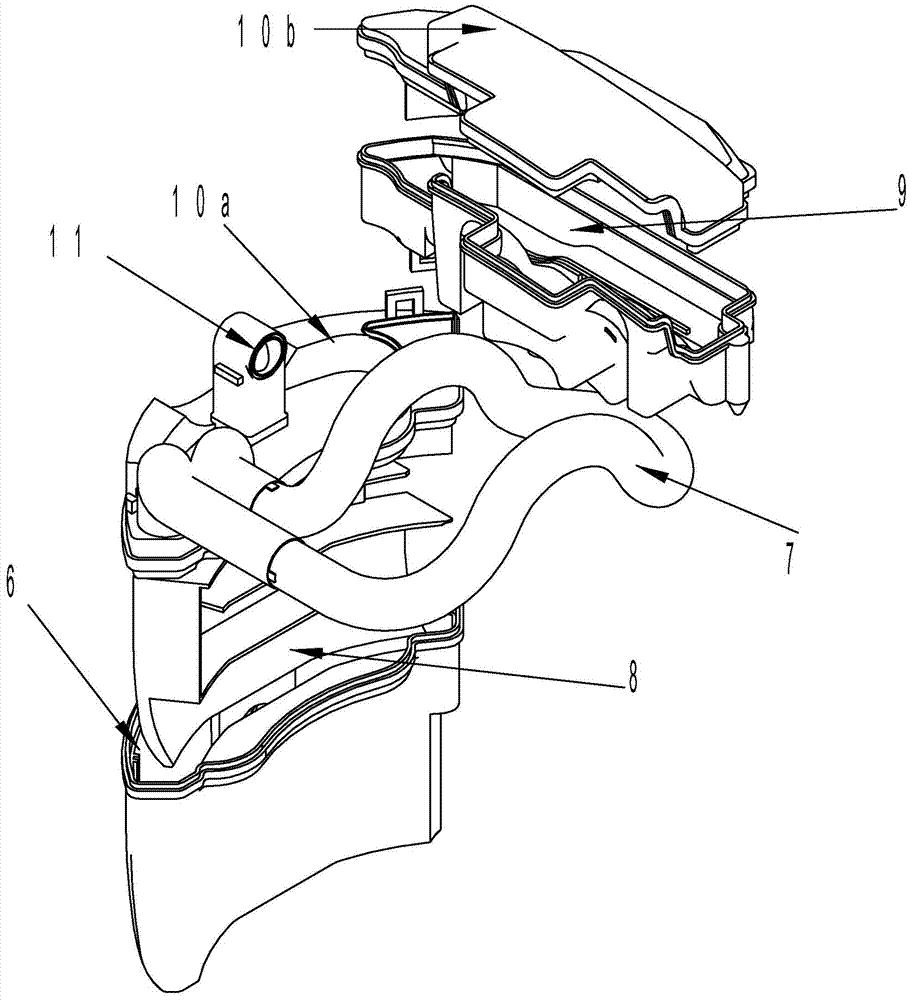

[0024] Such as figure 1 As shown, the suction structure of the refrigeration compressor of the present invention refers to the connection structure from the casing suction pipe 2 to the suction valve plate 11 and the compressor cylinder 1, including the bellows 4 and the suction muffler 10 . Please also see figure 2 and image 3 , the bellows 4 is connected to the housing 3 and is in line contact with the suction muffler 10 , or the bellows 4 is connected to the suction muffler 10 and is in line contact with the housing 3 . The suction muffler 10 includes a suction pipeline one 5 , an expansion chamber 6 , a suction pipeline two 7 , a suction pipeline three 8 and a resonance chamber 9 . Inhalation pipeline one 5, expansion cavity 6 and inhalation pipeline two 7 are connected in series. The suction pipeline 3 8 is connected with the resonant cavity 9 to form a resonant cavity assembly. By adjusting and optimizing the structural dimensions of each part of the suction struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com