Permanent magnet linear motor

A permanent magnet linear motor and body technology, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of uneven cooling, waste, and increase of parts, so as to suppress the body temperature rise, improve the cooling effect, and increase the volume of refrigerant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

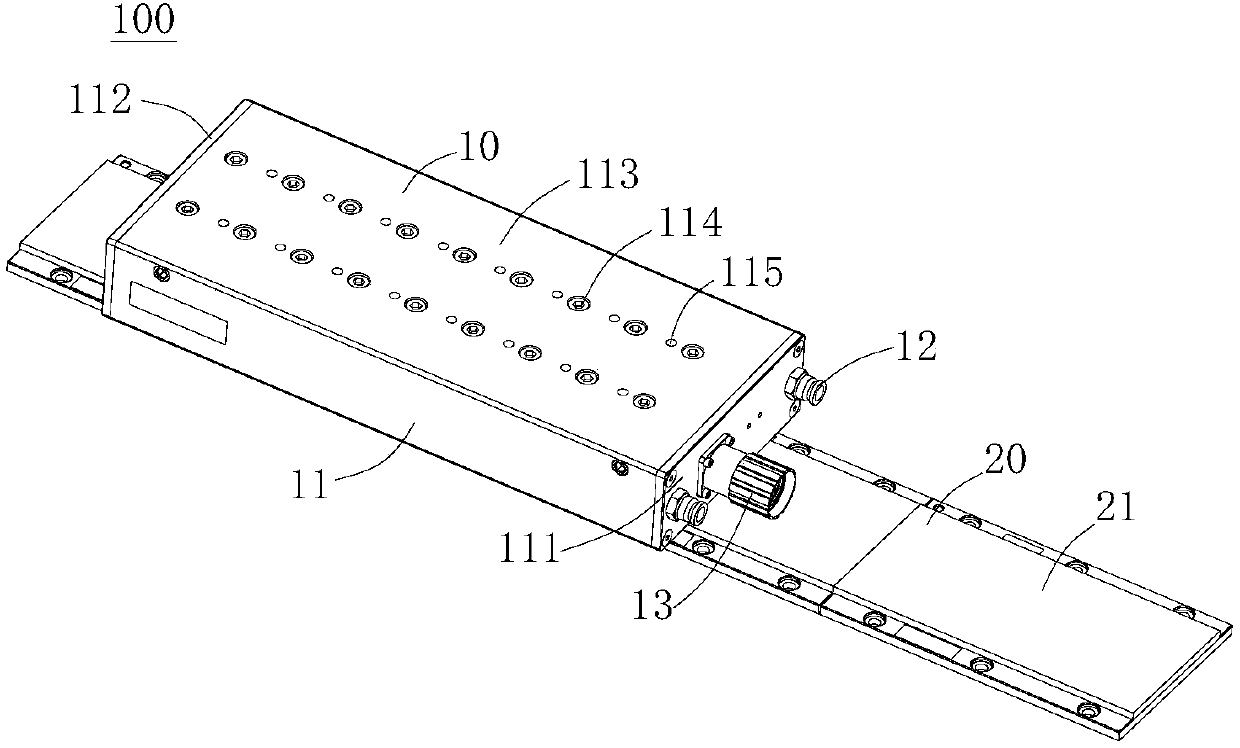

[0026] Such as figure 1 As shown, a permanent magnet linear motor 100 includes a primary assembly 10 and a secondary assembly 20 .

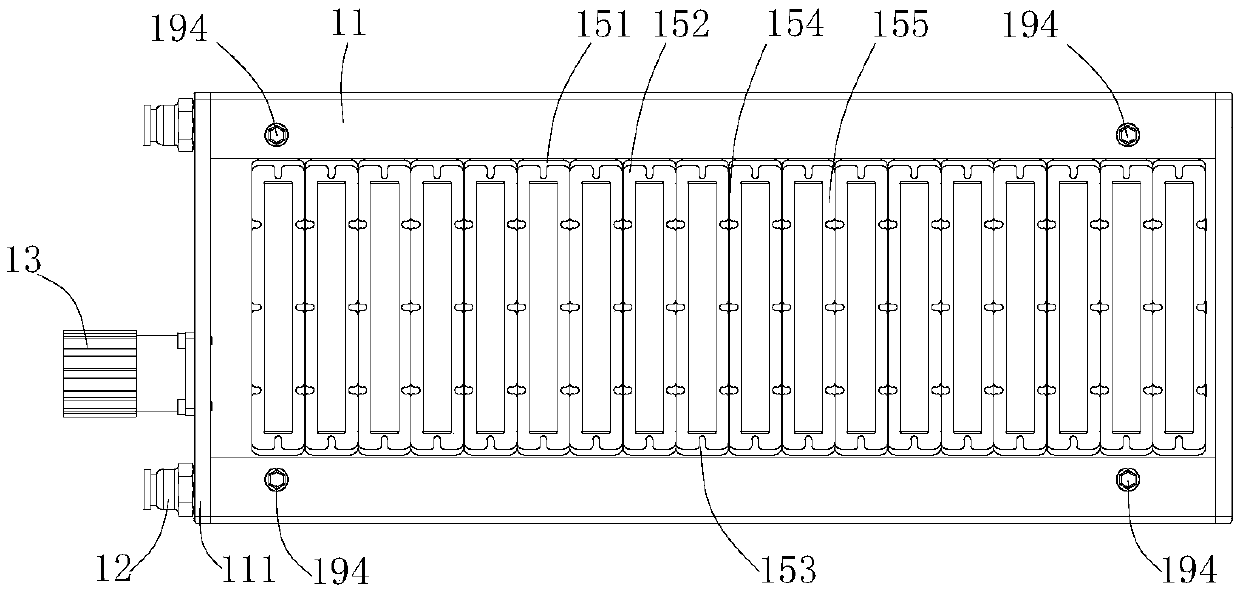

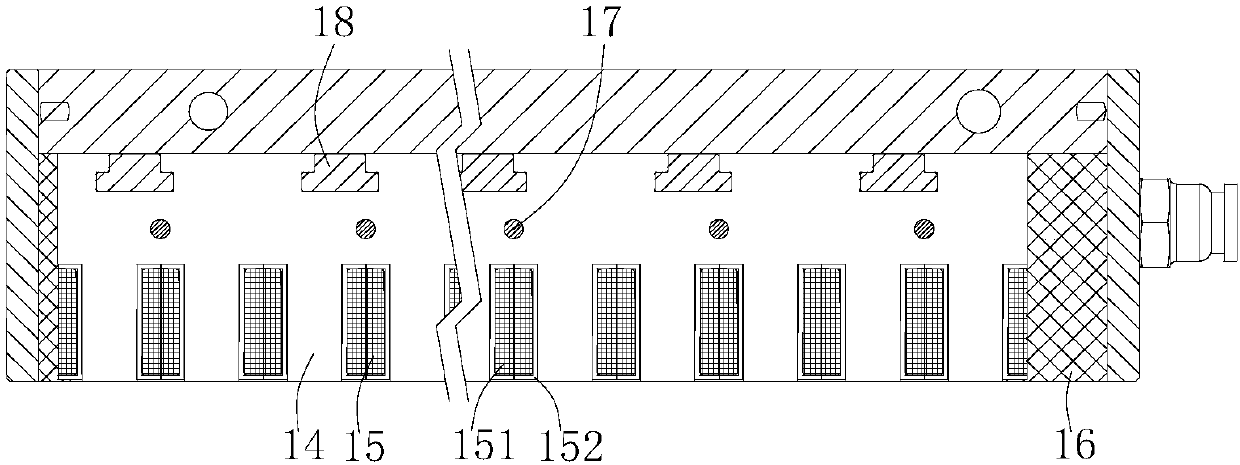

[0027] Such as Figure 2-6 As shown, the primary assembly 10 includes a body 11 , a cooling connector 12 , a power connector 13 , a primary core 14 , a coil winding 15 , a primary potting compound 16 , a connecting rod 17 , a connecting block 18 and a cooling channel 19 .

[0028] The body 11 includes a front fender 111 , a rear fender 112 and a top mounting plate 113 . The front protective plate 111 and the rear protective plate 112 are screwed to the two ends of the main body of the body 11 to form a mold cavity. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com