Microwave oven and exciter for microwave oven

A microwave oven and exciter technology, which is applied in the field of microwave ovens, can solve the problems that microwave power cannot be effectively suppressed, the transmission efficiency of exciters is affected, and the semiconductor microwave source is easily damaged, so as to reduce reflected power, expand radiation range, and improve transmission. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

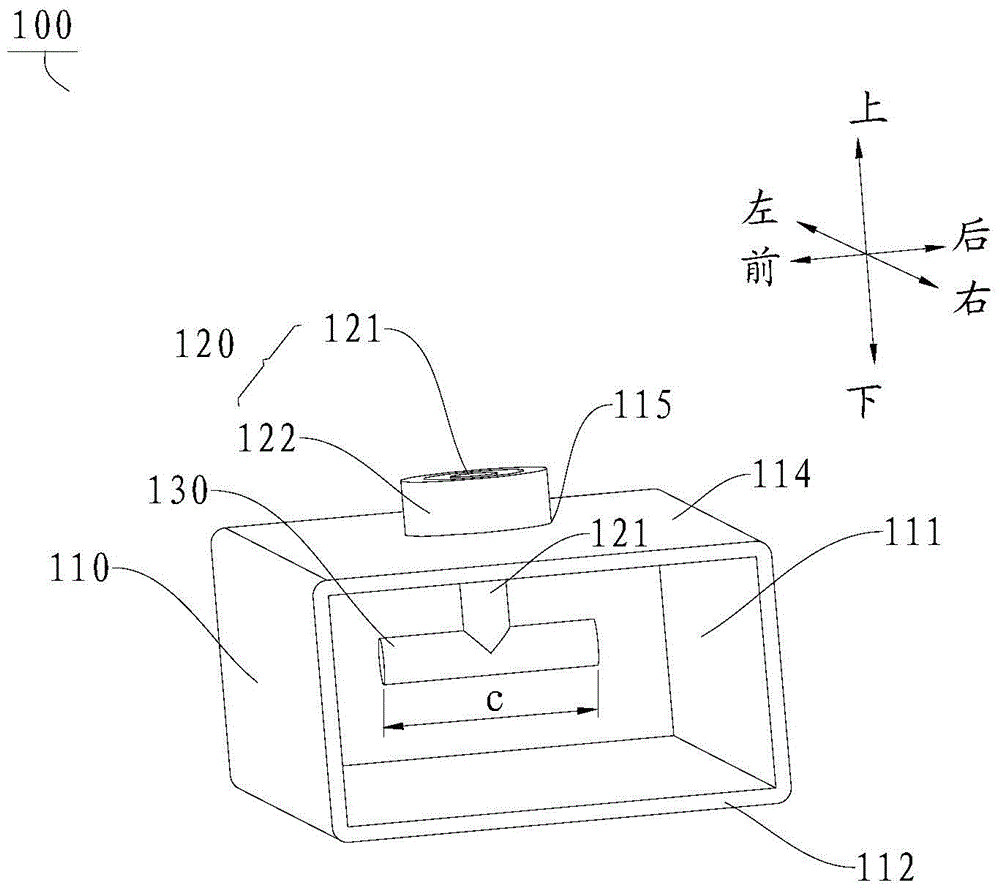

[0058] Such as image 3 , Figure 4 As shown, in this embodiment, there is one antenna rod 130 and is vertically connected to the lower end of the inner conductor 121 of the coaxial connector 120 . It should be noted that the angle between the central axis of the antenna rod 130 and the plane where the open end 112 of the waveguide box 110 is located can be determined according to the microwave frequency, for example, in image 3 In the example shown, the central axis of the antenna rod 130 is parallel to the plane where the open end 112 of the waveguide box 110 is located; Figure 4 In the example shown, the central axis of the antenna mast 130 is perpendicular to the plane in which the open end 112 of the waveguide box 110 lies. In this way, antenna rods 130 at different positions can be selected according to the frequency of microwaves, thereby achieving directional propagation of microwaves, improving the propagation efficiency of microwaves, and expanding the applicable...

Embodiment 2

[0060] Such as Figure 5 As shown, in this embodiment, the antenna rod 130 includes two antenna rods 130 intersecting each other and both communicate with the coaxial connector 120 . In other words, the two antenna rods 130 and the coaxial connector 120 intersect at the same point. Accordingly, the propagation efficiency of microwaves can be further improved. Here, the angle between the two antenna rods 130 is not specifically limited, for example, in a preferred example of the present invention, the two antenna rods 130 may be perpendicular to each other. Preferably, the coaxial connector 120 is connected to the midpoint of the two antenna rods 130 .

Embodiment 3

[0062] Such as Figure 6 , Figure 7 As shown, in this embodiment, the antenna rods 130 include three antenna rods 130 , at least one of which communicates with the coaxial connector 120 . Accordingly, the propagation efficiency of microwaves can be further improved.

[0063] It should be noted that there is no special limitation on the position of the connection point between the coaxial connector and the antenna rod 130, for example, in Figure 6 In the example shown, three antenna rods 130 are arranged in an H-shape, with one antenna rod 130' communicating with the coaxial connector 120. Preferably, the coaxial connector 120 is connected at the midpoint of the antenna mast 130'.

[0064] Again, in such Figure 7 In the example shown, three antenna masts 130 intersect at the same point and all communicate with the coaxial connector 120 . In other words, the three antenna rods 130 and the coaxial connector 120 intersect at the same point. Further, in such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com