Optical fiber assembly built in underground cable

A technology of optical fiber components and underground cables, applied in the direction of power cables, electrical components, optical components, etc., can solve problems such as uneven heat of optical fibers, affecting measurement accuracy, and inability to accurately measure the temperature of a predetermined area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

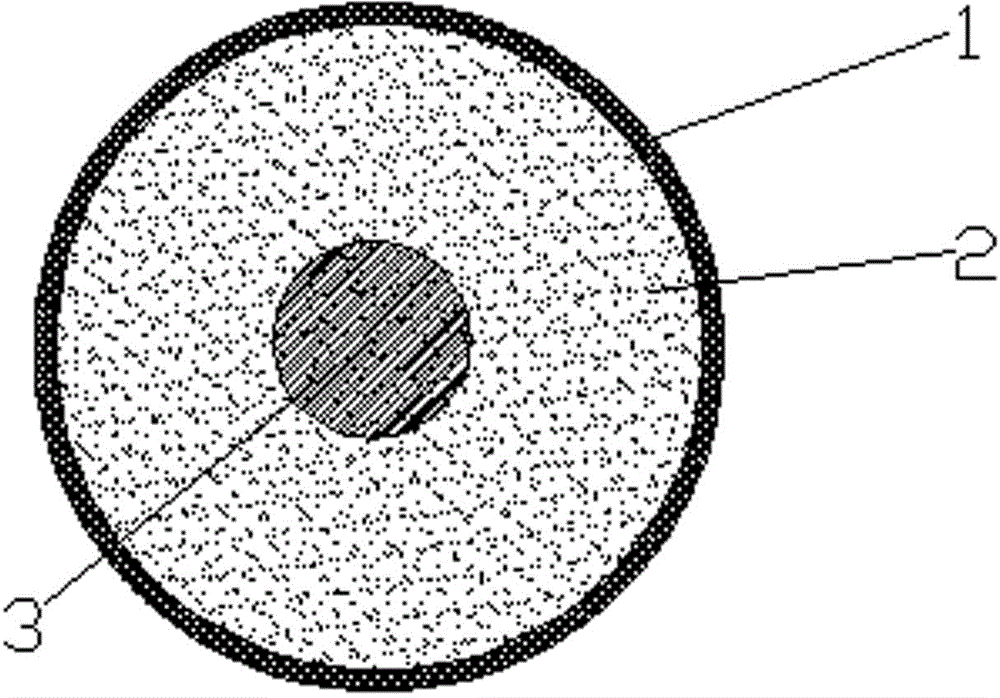

[0016] An optical fiber component placed in an underground cable, including a stainless steel pipe 1 and an optical fiber 3 inside the pipe, the optical fiber 3 is located on the axis of the stainless steel pipe 1, and the space between the optical fiber 3 and the stainless steel pipe 1 is filled with a heat-conducting material 2 that does not affect the optical signal. The heat conducting material 2 is optimally heat conducting glue.

[0017] When the underground power cable is supplied with current, the optical fiber 3 in the optical fiber assembly is located at the axis of the stainless steel pipe 1, supported by heat-conducting adhesive in all directions, and heated evenly, so the measured temperature value is accurate and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com