Flat plate voice coil motor

A voice coil motor, flat panel technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of motor error, increase motor heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

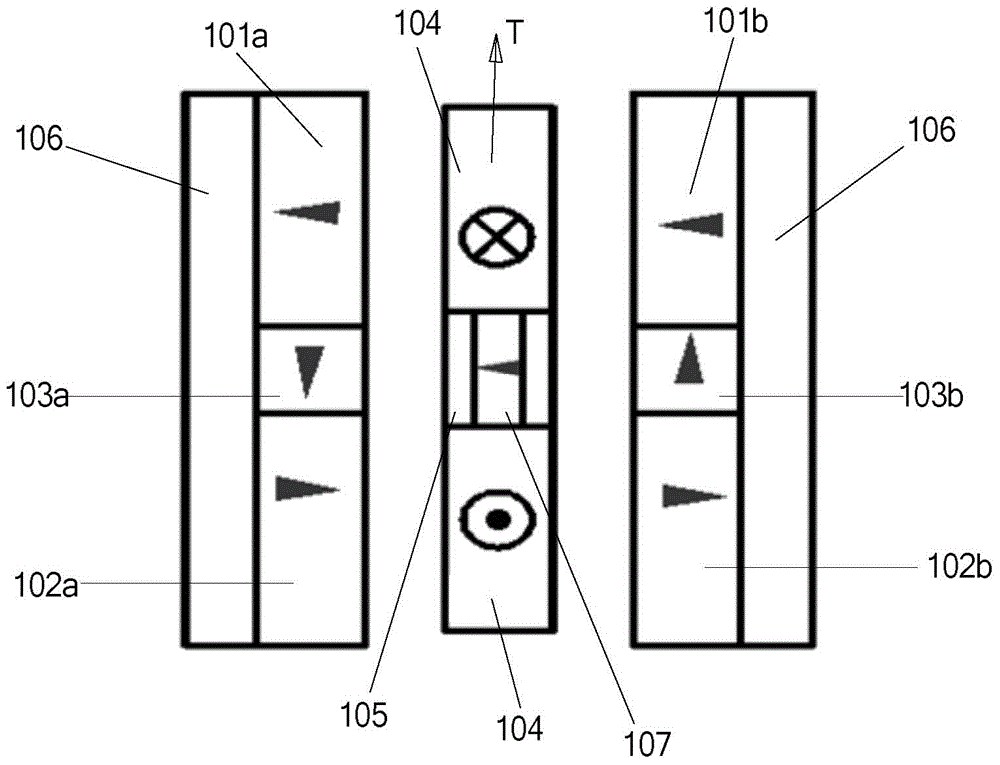

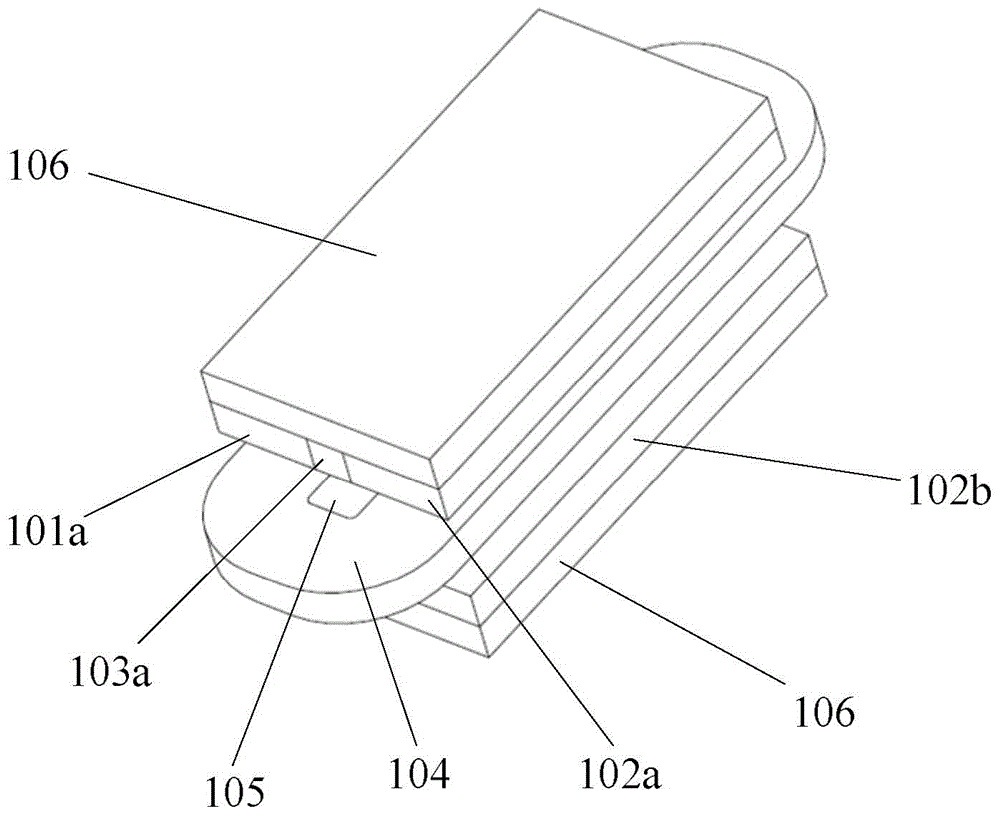

[0038] Please refer to figure 1 , the present embodiment provides a flat panel voice coil motor with a gravity compensation function, including a coil unit and two main pole units, and the two main pole units apply an ampere force T to the coil unit, and the inside of the coil unit It includes a weak magnetic small magnet 107, and the resultant force exerted by the two main magnetic pole units on the weak magnetic small magnet 107 is vertically upward, so as to realize the gravity compensation of the coil unit.

[0039] In this embodiment, a weak magnetic magnet 107 is set in the coil unit, and the magnetic repulsion or magnetic attraction force between the weak magnetic magnet 107 and the main magnetic pole unit always provides a vertical upward force for the coil unit, thereby realizing gravity compensation , and the setting of this structure is only to replace some components in the coil unit with weak magnetic magnets 107, which will neither affect the ampere force receive...

Embodiment 2

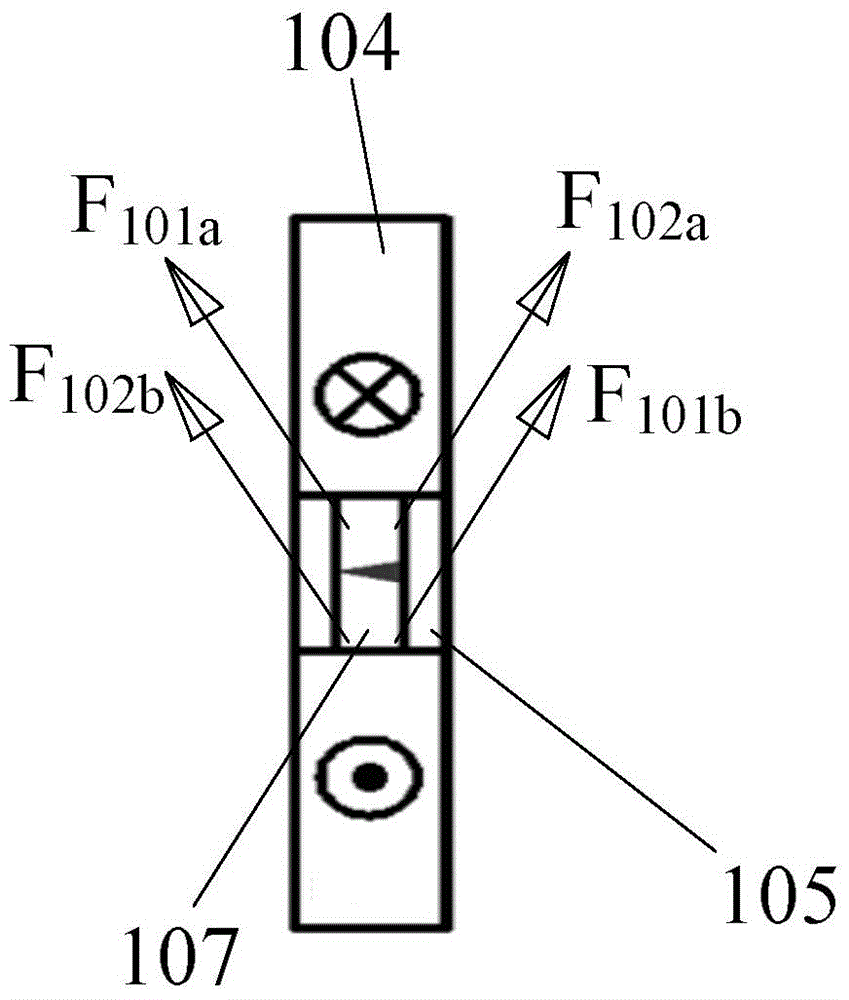

[0051] Please refer to Image 6 with Figure 7 , and combined with Figure 3 to Figure 5 , The difference between this embodiment and Embodiment 1 mainly lies in: the two main magnetic pole units form a vertical main magnetic field, and the two parts of the current-carrying conductors of the coil unit cutting the main magnetic field are arranged left and right. The magnetization direction of the weak magnetic small magnet 107 is the same as the direction of the ampere force applied to the coil unit. The two main pole magnets 101a and 102a located above the coil unit exert a vertical upward magnetic attraction force on the small weak magnet 107; the two main pole magnets 101b and 102b located below the coil unit 102b exerts a vertical upward magnetic repulsion force on the weakly magnetic small magnet 107 . Thus, through the effect of opposite sex attraction between the S pole and the N pole, such as Figure 7 For the diagonally upward F102a and F101a shown, the components ...

Embodiment 3

[0055] Please refer to Figure 8 to Figure 11 , the difference between this embodiment and embodiment 1 is only that there is no magnet 103 in this embodiment, and the mechanism of action is consistent with that of embodiment 1. The main magnetic pole unit in this embodiment includes two main magnetic pole magnets and a back iron, the main pole magnet is fixedly arranged on the back iron, and a distance is set between a pair of the main pole magnets; The length of the two weak small magnets along the direction of the two corresponding intervals. Except for this difference, other structures including the main magnetic pole unit, the structure of the coil unit and the arrangement of the components are consistent with those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com