Sealing structure of wire passing hole of electric device storage body

A technology of sealing structure and wire hole, which is applied in the field of passenger cars, can solve the problems of material inventory, sealing performance and operability, etc., and achieve the effects of good installation environment, reducing pollution and improving the sealing performance of the warehouse body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

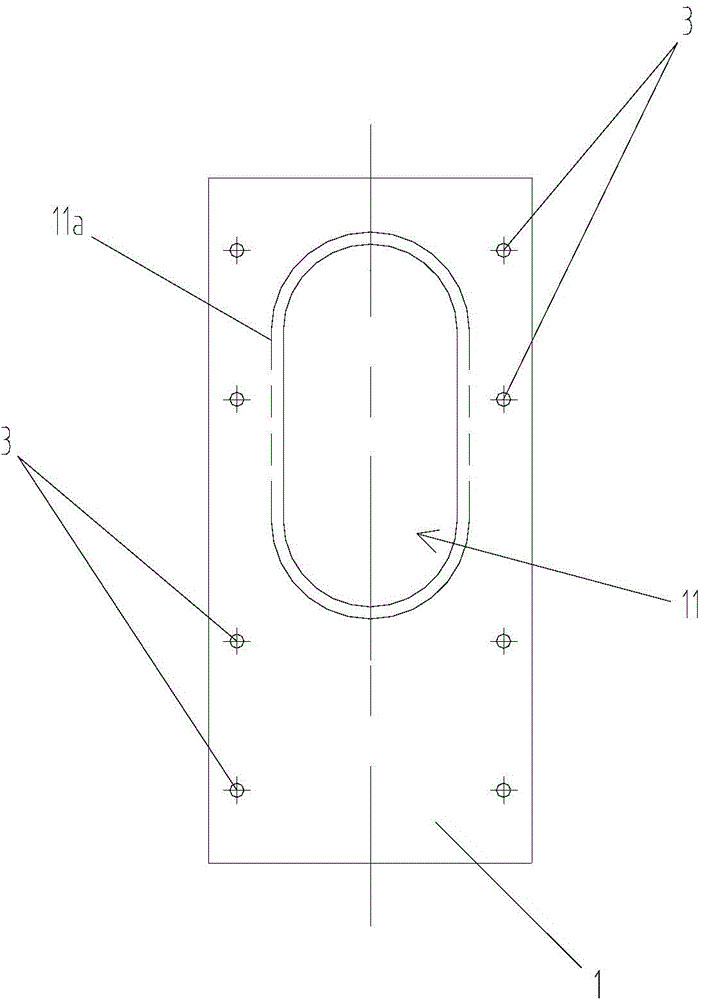

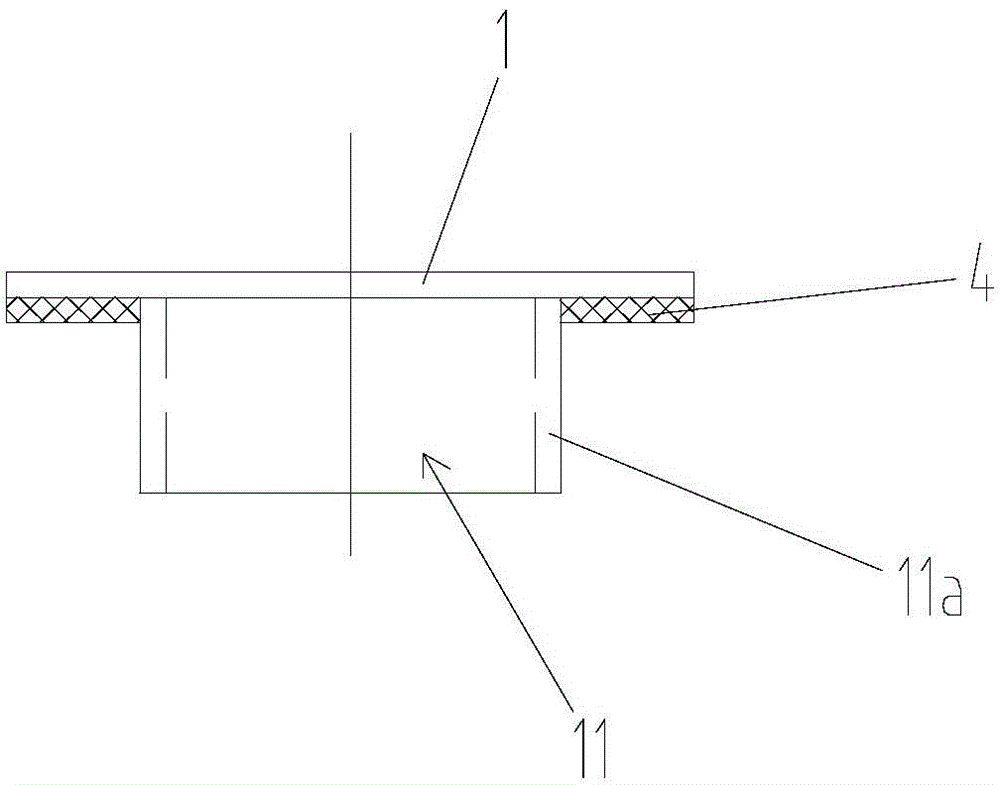

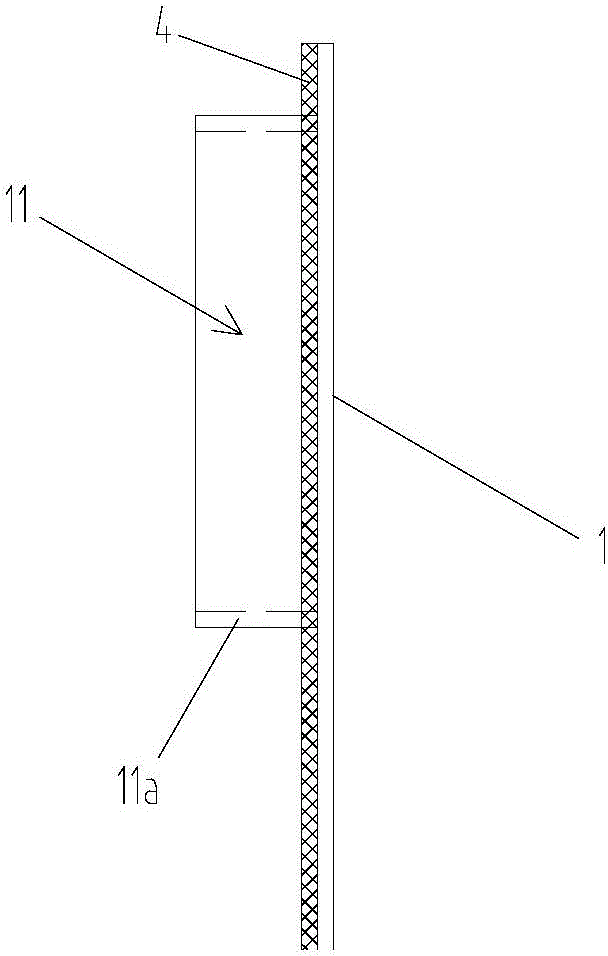

[0025] Figure 1 to Figure 6 A specific embodiment of the sealing structure of the wire hole of the electrical device compartment body of the present invention is shown, which includes a sealing plate 1 riveted and fixed on the electrical device compartment body, the sealing plate 1 is formed with a wire passing hole 11, In this example, the wire passing hole 11 is a waist-shaped hole. The cover plate 1 is also connected with a slide plate 2 that is closely attached to it by self-tapping screws. During actual assembly, the position of the slide plate 2 on the cover plate 1 is adjustable, and the slide plate 2 is shaped on The wire hole 11 matches the wire hole size adjustment notch 21 . In this example, the hole size adjustment notch 21 is a semicircular notch.

[0026] Refer again Figure 1 to Figure 6 As shown, the assembly method of this sealing structure of the present embodiment is introduced as follows:

[0027] 1) First, use rivets to fix the sealing plate 1 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com