Tubular modularized waste gas purification treatment device

A technology of exhaust gas purification and treatment device, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of reduced purification treatment efficiency, inability to adjust the amount of exhaust gas treatment, insufficient illumination, etc., to improve purification treatment. Efficiency, the effect of extending the exhaust gas purification path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

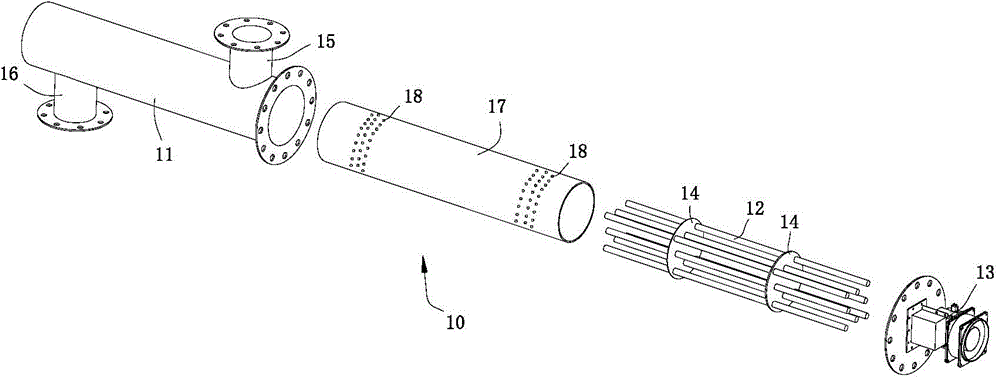

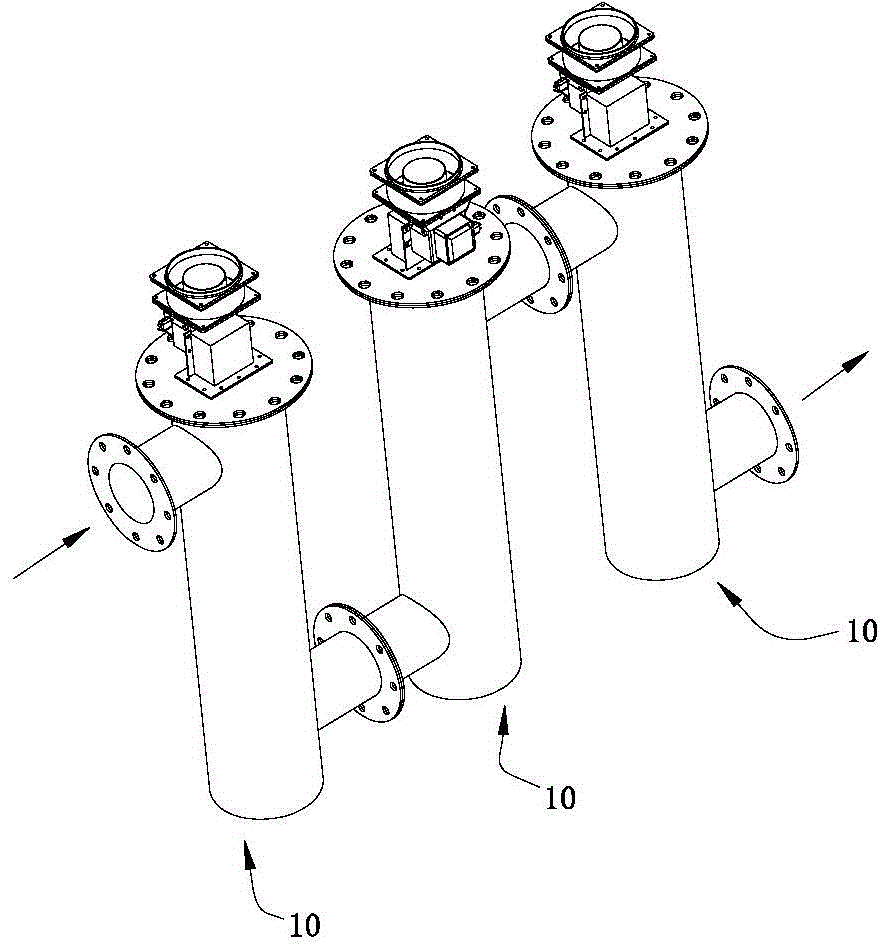

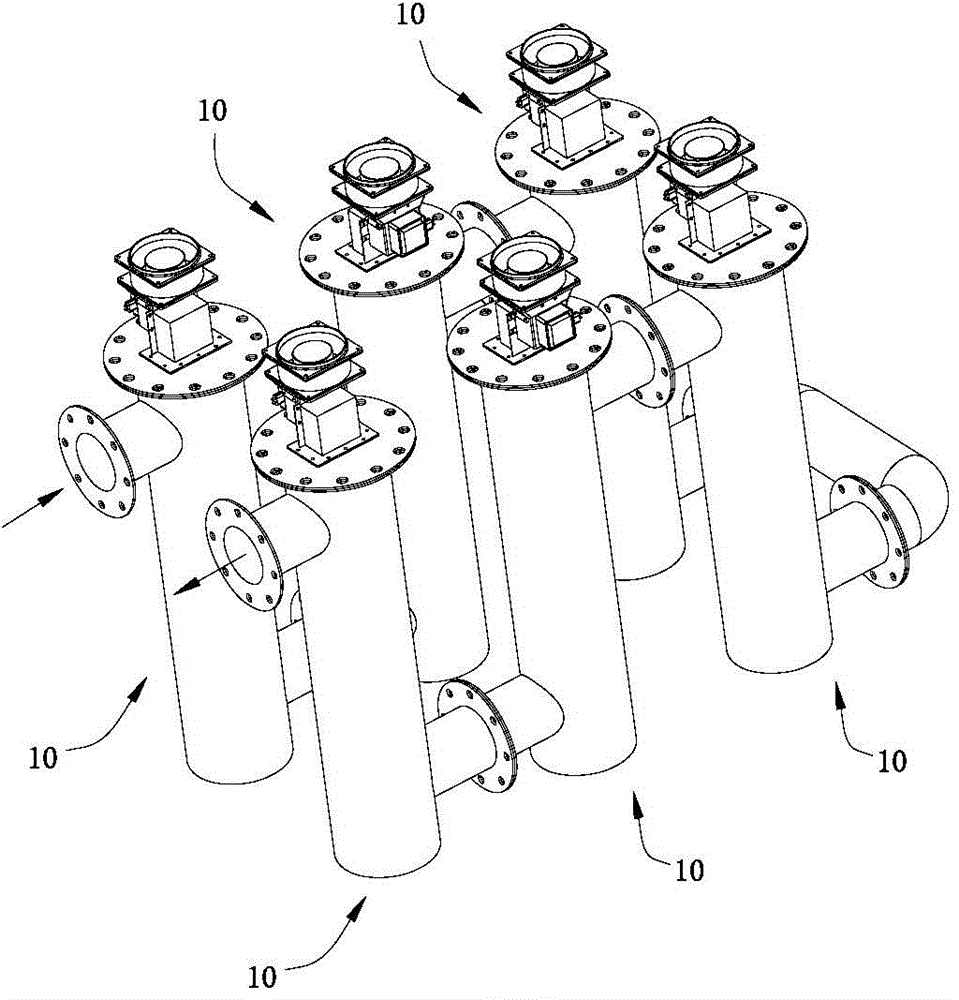

[0020] Refer to 1 to image 3 , a tubular modular exhaust gas treatment device of the present invention, comprising a plurality of pipeline modules 10 connected end to end, the pipeline module 10 includes a pipeline 11, a number of electrodeless ultraviolet lamp tubes 12 arranged in the pipeline 11, and arranged at one end of the pipeline 11 Electromagnetic wave emitting source 13 for irradiating each electrodeless ultraviolet lamp tube 12 to release ultraviolet rays, each electrodeless ultraviolet lamp tube 12 is arranged axially parallel to the pipeline 11 along the airflow direction.

[0021] Wherein, each pipeline module 10 is an exhaust gas purification treatment unit, and each pipeline module 10 is arranged with a plurality of electrodeless ultraviolet lamp tubes 12 along the axial direction of the pipeline 11, and several support plates 14 are arranged at intervals in the pipeline, and the support plate 14 is provided with A plurality of through holes are used for inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com