Hobbing fixture for dual gears

A technology of double gear and gear hobbing fixture, which is applied to gear tooth manufacturing devices, components with teeth, belts/chains/gears, etc., can solve the problems of low production efficiency, difficulty in clamping double gears, etc. High efficiency, reduce the influence of machining accuracy, and increase the effect of positioning area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

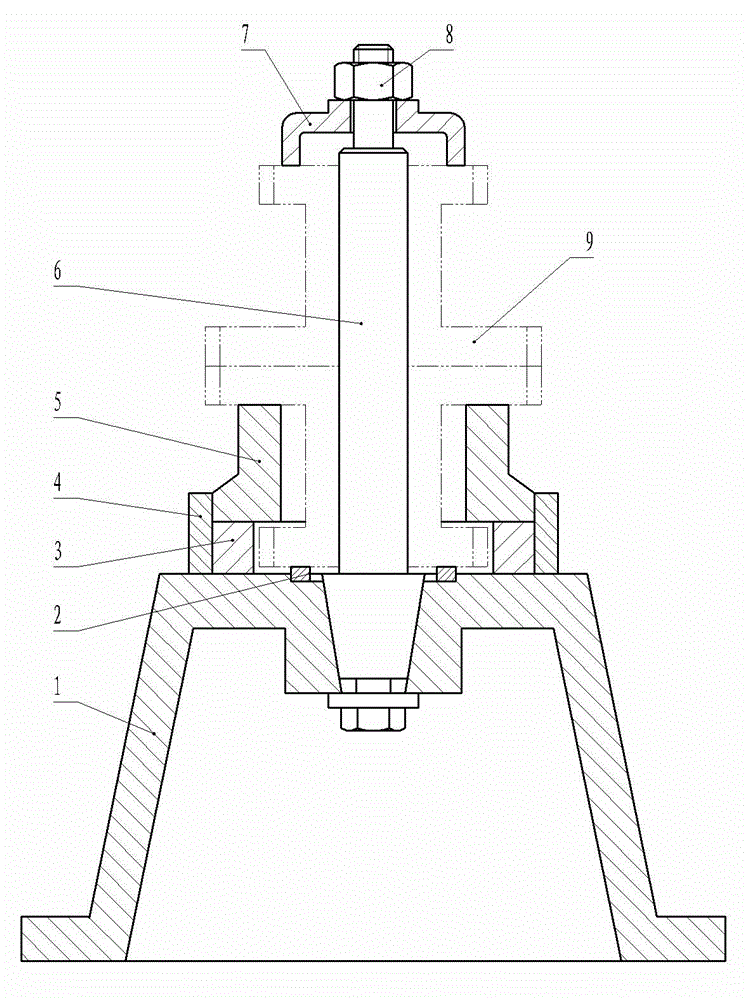

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

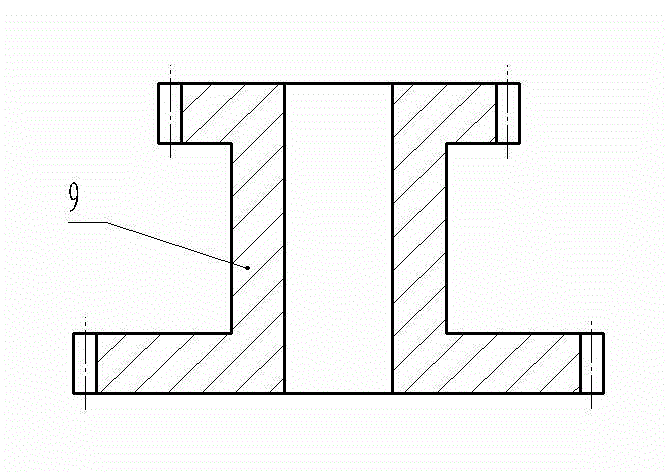

[0013] Such as figure 2 The gear hobbing fixture of a double gear shown includes a clamp body 1, on which a mandrel 6 for wearing two double gears 9 is mounted, and a nut 8 and a pressure plate 7 are installed on the upper end of the mandrel 6, The lower end of the mandrel 6 has a cone part that cooperates with the clamp body 1, and a bolt and a backing plate that are fixedly connected with the clamp body 1 are installed under the cone part; a washer 2 is installed on the outside of the mandrel 6 at the upper end of the clamp body 1 , The gasket 2 is a copper pad, and the outer side of the gasket 2 is equipped with an inner positioning sleeve 3 and an outer positioning sleeve 4 successively, and an open sleeve 5 which is offset against the inner side of the outer positioning sleeve 4 is installed on the top of the inner positioning sleeve 3 .

[0014]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com