Hovercraft slew rate maintaining control method adopting guide module

A technology to maintain control and slew rate, applied in the direction of air cushion, transportation and packaging, vehicle parts, etc., can solve problems such as no mention of slew rate automatic maintenance control, no open documents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

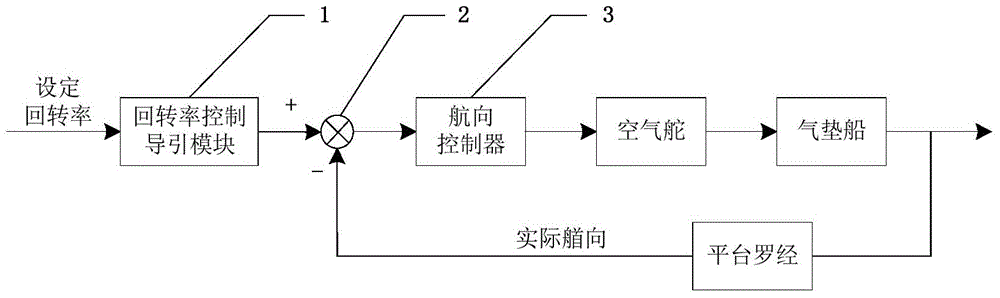

[0038] The principle of the hovercraft slewing rate control system with the guidance module proposed by the present invention is as follows: figure 1 As shown, the process is as follows:

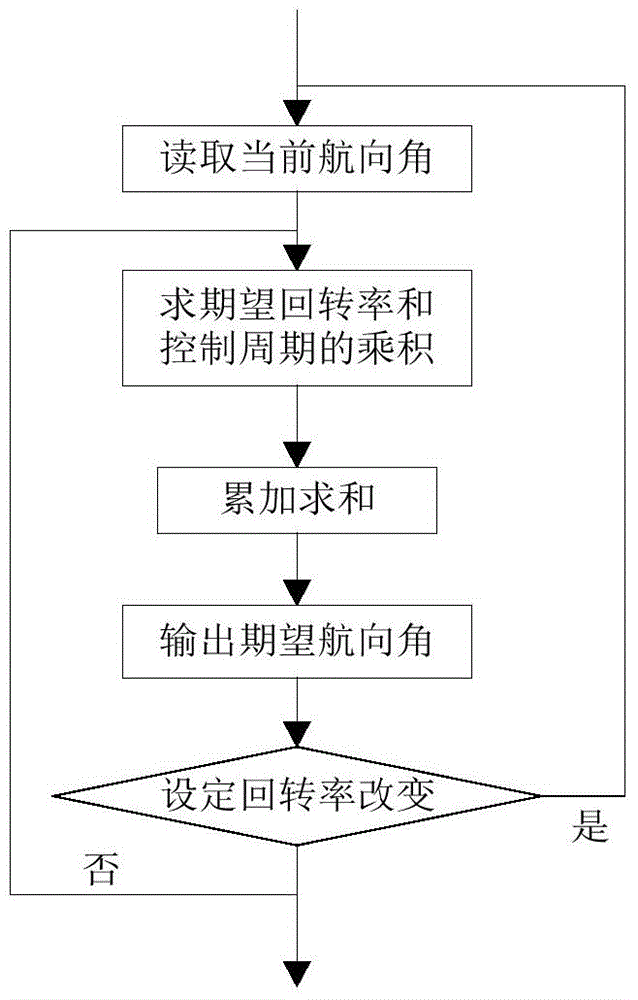

[0039] 1. The slewing rate control guidance module calculates the expected heading angle at the current moment according to the set slewing rate and the current actual heading angle;

[0040] 2. The comparator compares the expected heading obtained by the guidance module with the current actual heading of the platform compass to obtain the heading deviation;

[0041] 3. The controller calculates the rudder angle command according to the heading deviation and sends it to the air rudder system.

[0042] 4. The rudder angle of the air rudder changes, so that the torque on the hovercraft changes, so as to achieve the set slewing rate.

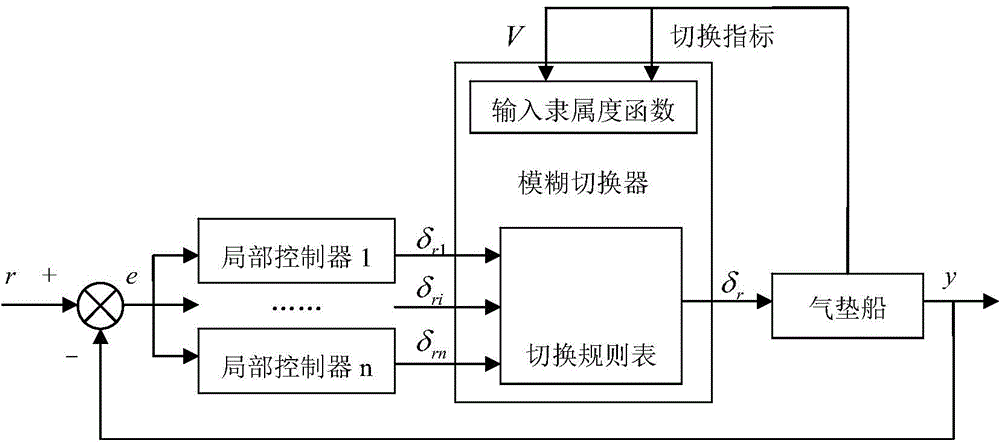

[0043] The hovercraft slewing rate aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com