a floor system

A technology for flooring and wood-plastic flooring, applied in the direction of floors, buildings, building structures, etc., can solve the problems of time-consuming, labor-intensive, complicated operation, etc., and achieve the effect of improving installation efficiency, reducing labor costs, and facilitating installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

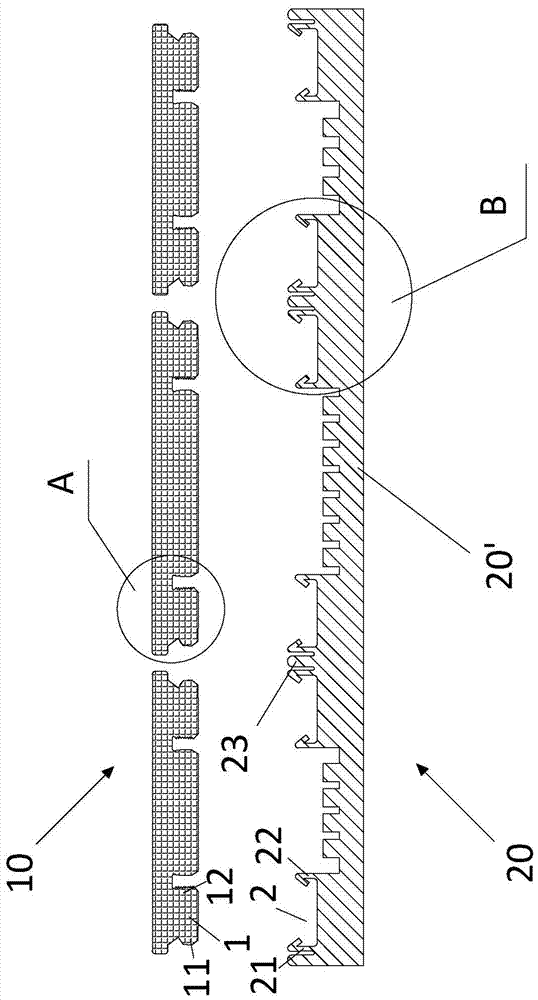

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] This specific embodiment is only an explanation of the present invention, but not a limitation of the present invention. Any changes made by those skilled in the art after reading the description of the present invention will be protected by the patent law as long as they are within the protection scope of the claims.

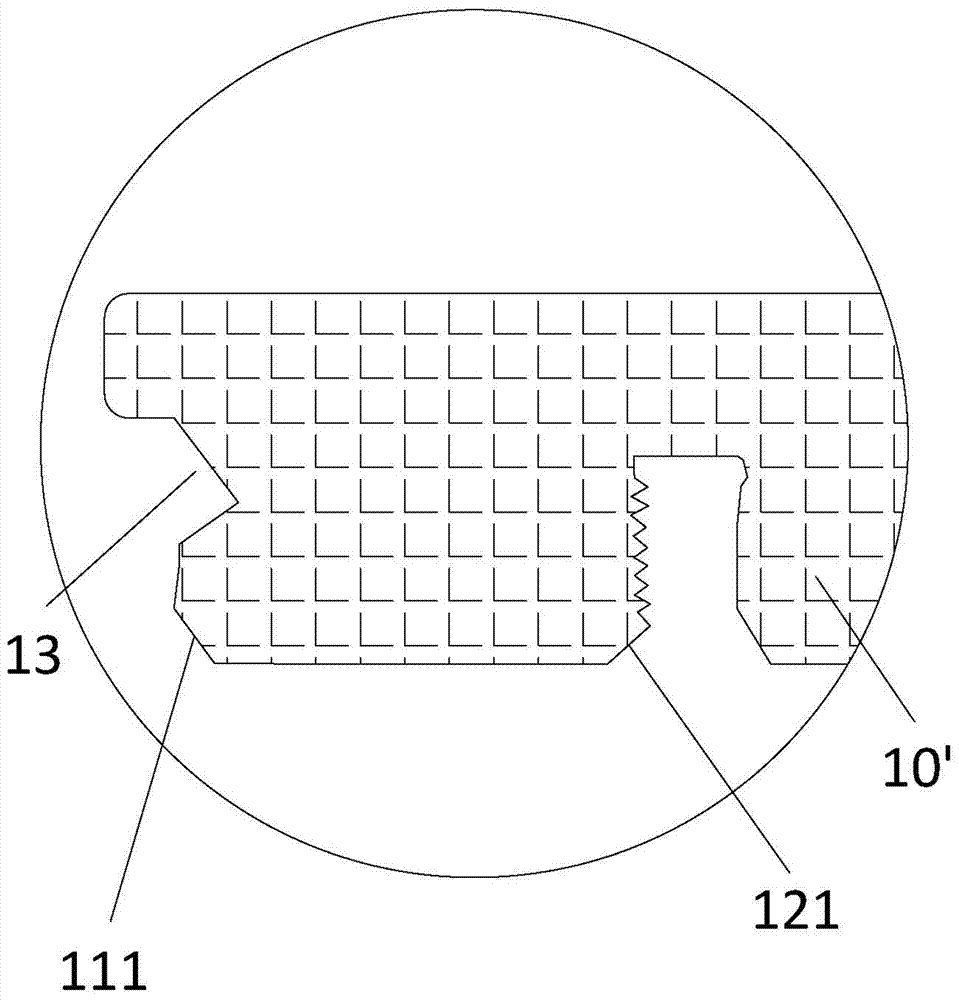

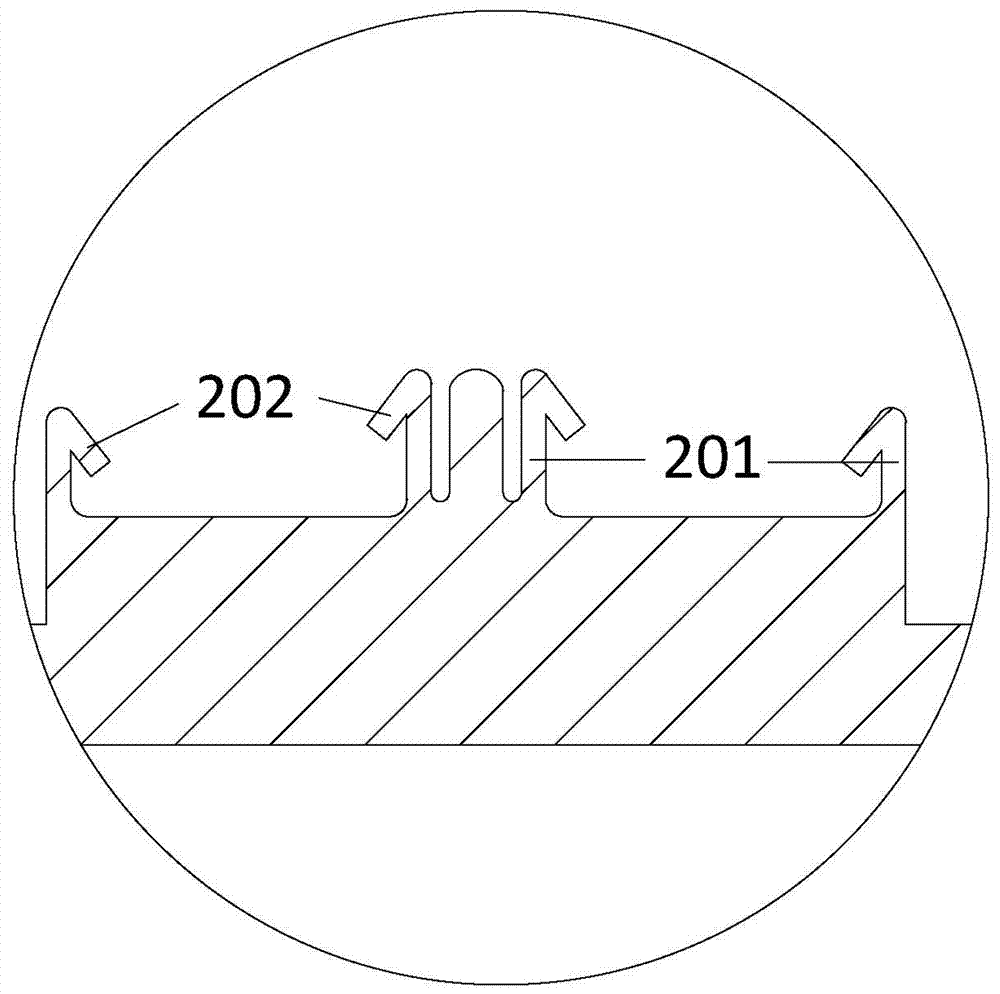

[0031] Such as figure 1 As shown, a wood-plastic floor 10 has an upper layer including a surface and a lower layer including a bottom surface. The lower layer of the wood-plastic floor 10 has a downwardly disposed tenon 1 , a first snap-action portion 11 is provided on the side end of the tenon 1 near the outside of the floor, and a second snap-action portion 12 is provided on the other side end.

[0032] Such as figure 2 As shown, the first buckle action part 11 is a protrusion with the opening direction facing the outer end, the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com