Novel guiding axle

A guide shaft, a new type of technology, applied in the direction of shafts, shafts and bearings, mechanical equipment, etc., can solve the problems of failing to meet the C-level explosion-proof standard, and achieve the effect of good sealing, strong pressure resistance, and absolute isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

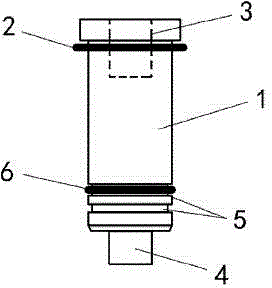

[0010] Such as figure 1 As shown, a new type of guide shaft is characterized in that it includes a body 1 and a sealing washer 2, the body 1 is made of alloy powder extruded, the upper end of the body 1 is provided with a groove 3, and the lower end of the body 1 is provided with a convex Block 4, the side wall of the body 1 is provided with an annular groove 5, and a sealing ring 6 is provided on the annular groove 5.

[0011] Finally, it should be noted that: the above-mentioned embodiment is only an example for clearly illustrating the present invention, rather than a limitation to the implementation mode. For those of ordinary skill in the art, other embodiments can be made on the basis of the above description. Changes or changes in different forms are not necessary and cannot be exhaustive for all implementations, and obvious changes or changes derived therefrom are still within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com