Anti-skidding hub bearing

A technology of anti-skid wheels and bearings, applied in bearings, bearing components, shafts and bearings, etc., can solve problems such as slippage, large safety hazards, and reduced bearing accuracy, performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

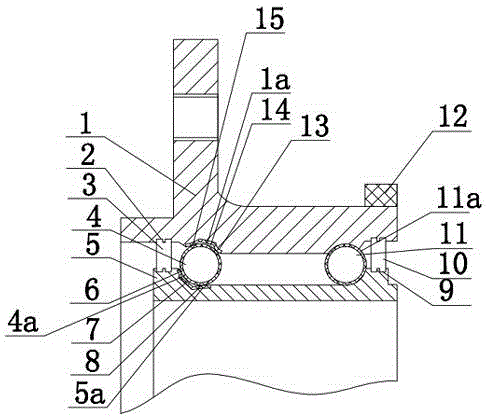

[0013] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0014] As shown in the figure, the anti-skid hub bearing includes an inner ring 5 and an outer ring 1, inner balls 4 and outer balls 11 are arranged in cooperation between the inner ring 5 and the outer ring 1, and inner balls 4 and outer balls 11 are arranged in cooperation between the inner ring 5 and the outer ring 1. The sealing member 3 and the outer sealing member 10 form a sealed space for encapsulating grease. The outer end of the outer ring 1 is provided with a locking ring 12, which is characterized in that the first protrusion of the outer ring is arranged in the inner ball groove of the outer ring 1. The raised portion 15, the concave portion 14 of the outer ring, the second convex portion 13 of the outer ring, the first convex portion 6 of the inner ring, the concave portion 7 of the inner ring, and the second convex portion 8 of the inne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com