Deepwater subsea pipeline stopping laying method

A technology for submarine pipelines and pipelines, which is applied in pipeline laying and maintenance, mechanical equipment, pipes/pipe joints/fittings, etc. It can solve the problems of pipeline torsion, difficult control and installation of heads, etc., and achieve the effect of solving positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

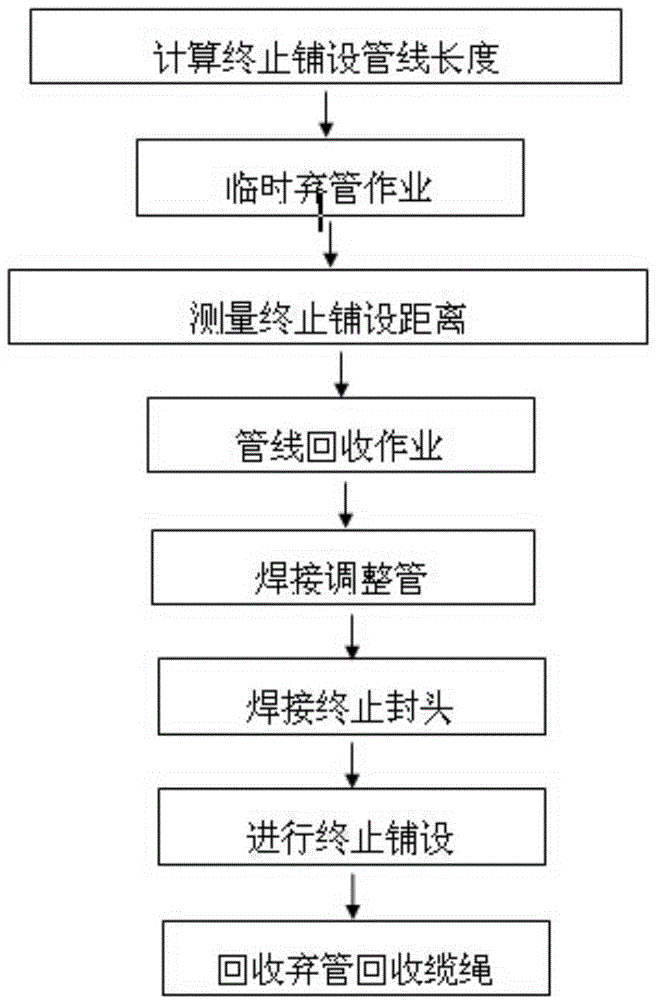

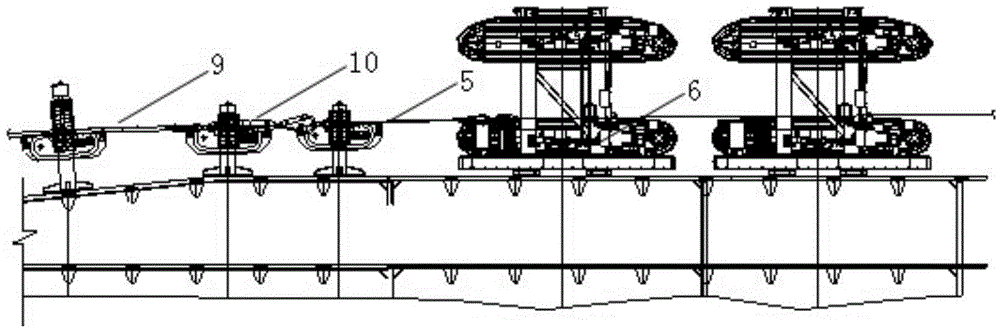

[0039] Such as figure 1 — image 3 Shown, the present invention adopts following steps:

[0040] The first step is to calculate the length of the suspension line of the pipeline from the soil impact point to the operation line; the specific method is:

[0041] (1) Use the underwater robot 2 to determine the kilometer point (KP) value of the mud landing point, and calculate the length from the mud landing point to the pipeline suspension line of the operation line according to parameters such as water depth and pipeline diameter;

[0042] (2) According to the kilometer point (KP) value of the target point where the laying is terminated, the seabed laying distance of the terminated head is roughly calculated first; if the accuracy of the laying end is required to be high, for example, the target point is within the range of 3mX6m, high-precision measurement methods must be adopted , the specific steps of this method are:

[0043] ① Mark a point on the working line pipeline 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com