A method for measuring the ash content of filled paper through oxygen combustion

A paper and oxygen technology, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of high ashing time and energy cost, large influence of environmental factors, slow heating process, etc., to meet the requirements of high thermal stability and lasting strength, Avoid fly ash phenomenon and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

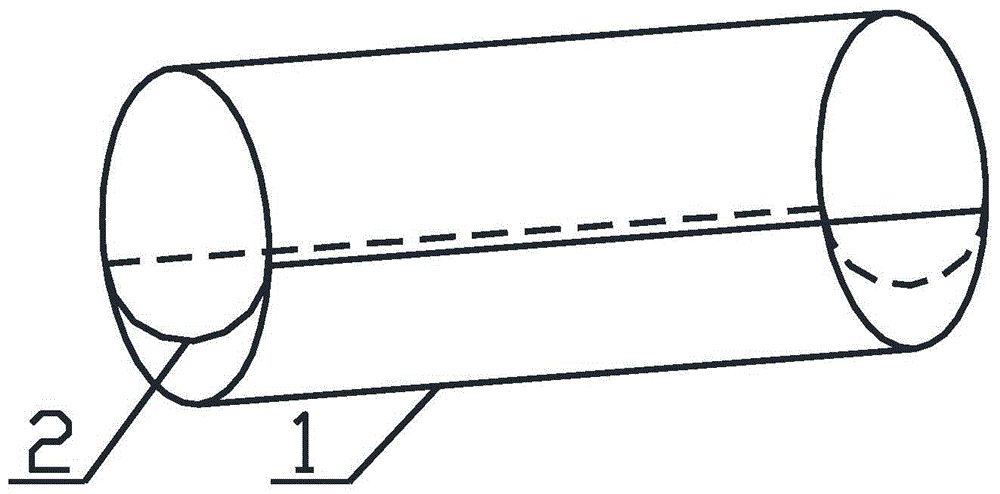

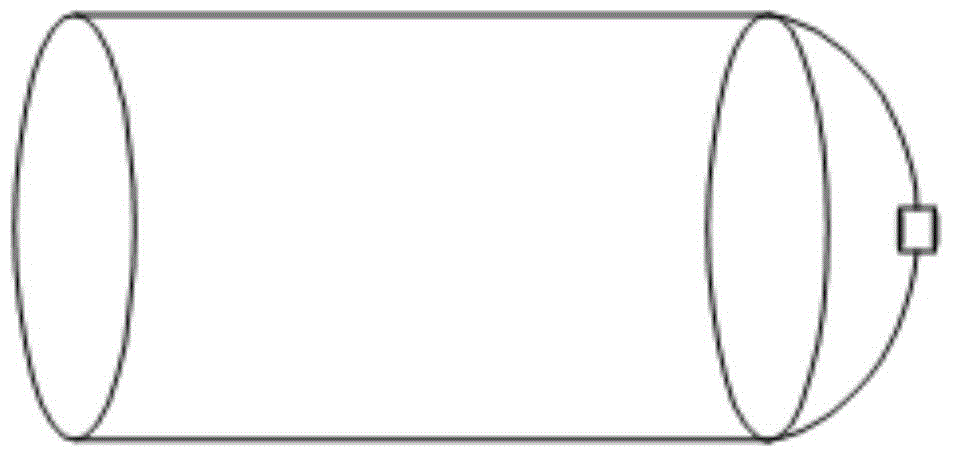

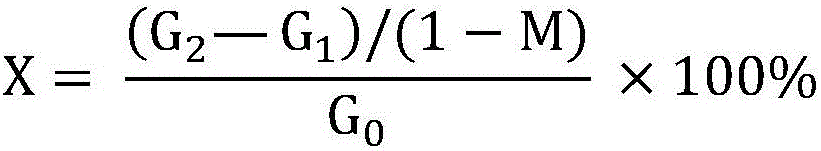

Embodiment 1

[0046] Grinding calcium carbonate (GCC) plus filling paper (quantitative 125g / m 2 ), take a 0.5g paper sample and cut it into a paper strip with a length of 50mm and a width of 40mm, then place the paper strips completely overlapping and then fold them in half along the length direction to obtain a half-folded paper sample. The angle after folding in half is controlled at 70-145 degrees. Weigh the weights of the folded paper sample and the combustion device on an analytical balance (0.0001g), place the folded paper sample in the middle of the combustion device, and then push the combustion device into the combustion chamber. Open the bottle valve of the oxygen tank so that oxygen enters the combustion chamber after passing through the air flow meter. After pre-passing oxygen for 20 seconds (the flow rate is 3L / min), use a lighter to ignite the folded paper sample, so that the paper sample burns rapidly under the condition of oxygen combustion, and wait for the paper sample Aft...

Embodiment 2

[0050] Precipitated calcium carbonate (PCC) plus paper (quantitative 70g / m 2 ), take a 0.5g paper sample and cut it into strips with a length of 70mm and a width of 40mm, then place the paper strips completely overlapping and then fold them in half along the middle of the length direction to obtain a half-folded paper sample. The angle after folding in half is controlled at 70-145 degrees. Weigh the weights of the folded paper sample and the combustion device on an analytical balance (0.0001g), place the folded paper sample in the middle of the combustion device, and then push the combustion device into the combustion chamber. Open the bottle valve of the oxygen tank so that the oxygen enters the combustion chamber after passing through the air flow meter. After pre-passing the oxygen for 10 seconds (the flow rate is 6L / min), use a lighter to ignite the folded paper sample, so that the paper sample burns rapidly under the condition of oxygen combustion, and the paper sample is ...

Embodiment 3

[0055] Talc powder plus paper (quantitative 70g / m 2 ), take 0.5g paper sample and cut it into 90mm long and 40mm wide paper strips, then place the paper strips completely overlapped and then fold them in half along the length direction to get half folded paper samples, the angle after folding is controlled at 70-145 degrees. Weigh the weights of the folded paper sample and the combustion device on an analytical balance (0.0001g), place the folded paper sample in the middle of the combustion device, and then push the combustion device into the combustion chamber. Open the bottle valve of the oxygen tank so that oxygen enters the combustion chamber after passing through the air flow meter. After pre-passing the oxygen for 15 seconds (the flow rate is 4L / min), use a lighter to ignite the folded paper sample, so that the paper sample burns rapidly under the condition of oxygen combustion, and the paper sample is ready. After the combustion is over, close the valve of the oxygen ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com