Array substrate and manufacturing method thereof and touch detecting method of touch display device

An array substrate, self-capacitance touch technology, applied in the input/output process of data processing, instruments, calculations, etc., can solve the problems of touch sensitivity drop, touch resolution drop, etc., to achieve a good touch experience, reduce The effect of small touch response time and high detection resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

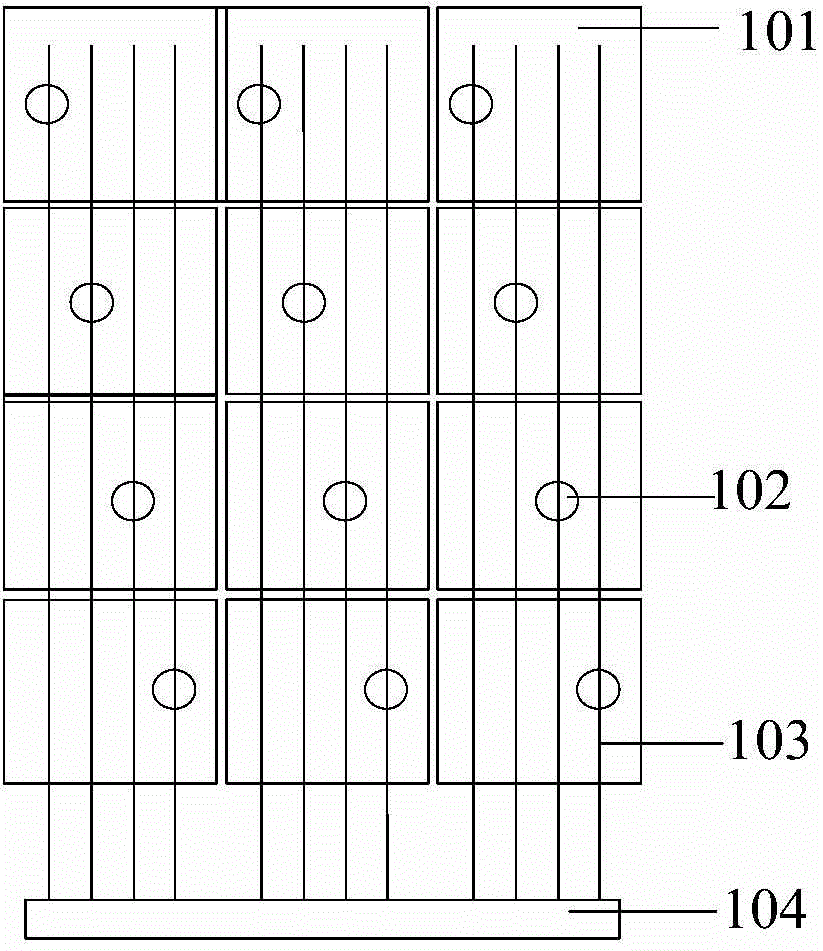

[0020] The inventor analyzed the in-cell touch screen based on the self-capacitance principle in the prior art, and found that in the in-cell touch screen based on the self-capacitance principle, the size of each self-capacitance touch electrode on the array substrate is consistent. figure 1 is a schematic diagram of an existing array substrate, such as figure 1 As shown, a plurality of electrodes 101 with the same area are provided in the conventional array substrate, and the electrodes 101 are electrically connected to the chip 104 through wires 103 in one-to-one correspondence. Wherein, each trace 103 is electrically connected to a corresponding electrode 101 through a via hole 102 on an insulating layer (not shown).

[0021] In order to ensure higher touch sensitivity, the size of existing self-capacitance touch electrodes is usually relatively large. For example figure 1 In the electrode 101 in, the length of each side is about 4 mm. If a finger is used for touch, sinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com