Electomotor

A technology of electric motors and pole shoes, applied in the field of electric motors, can solve the problems of low torque density, high cost, and expensive motors, etc., and achieve the effect of compact structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

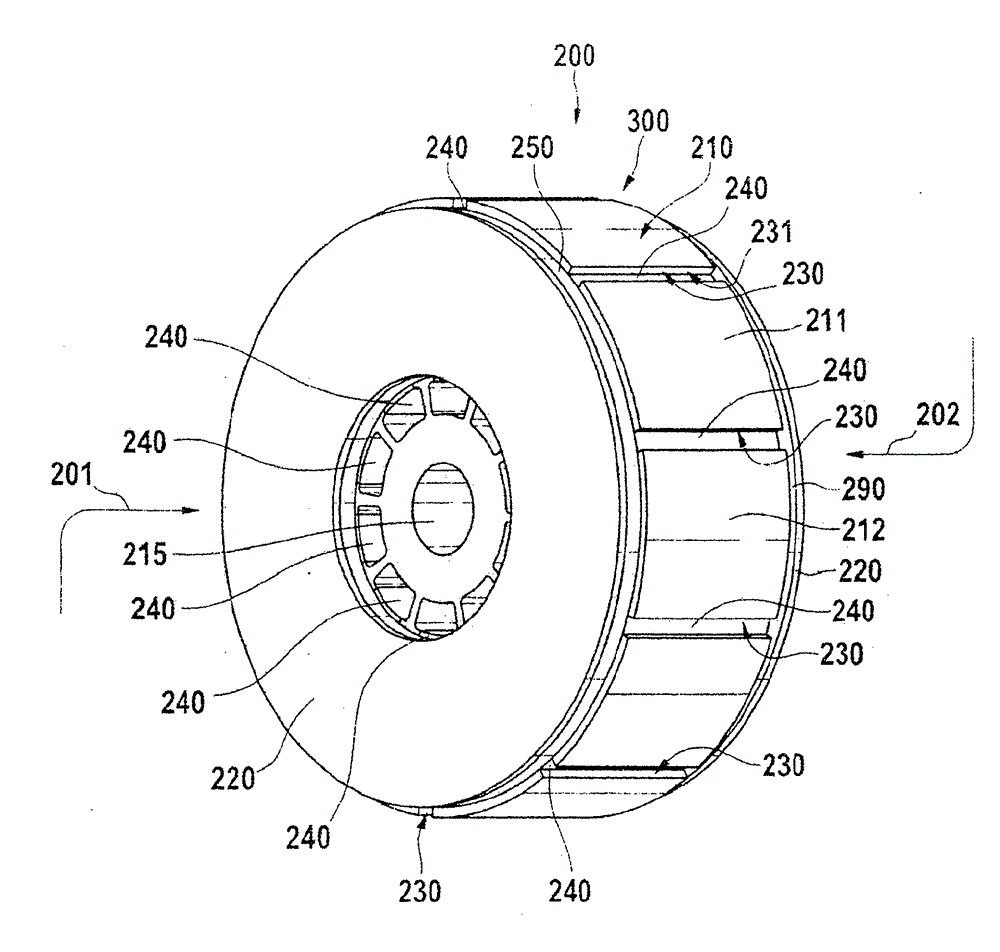

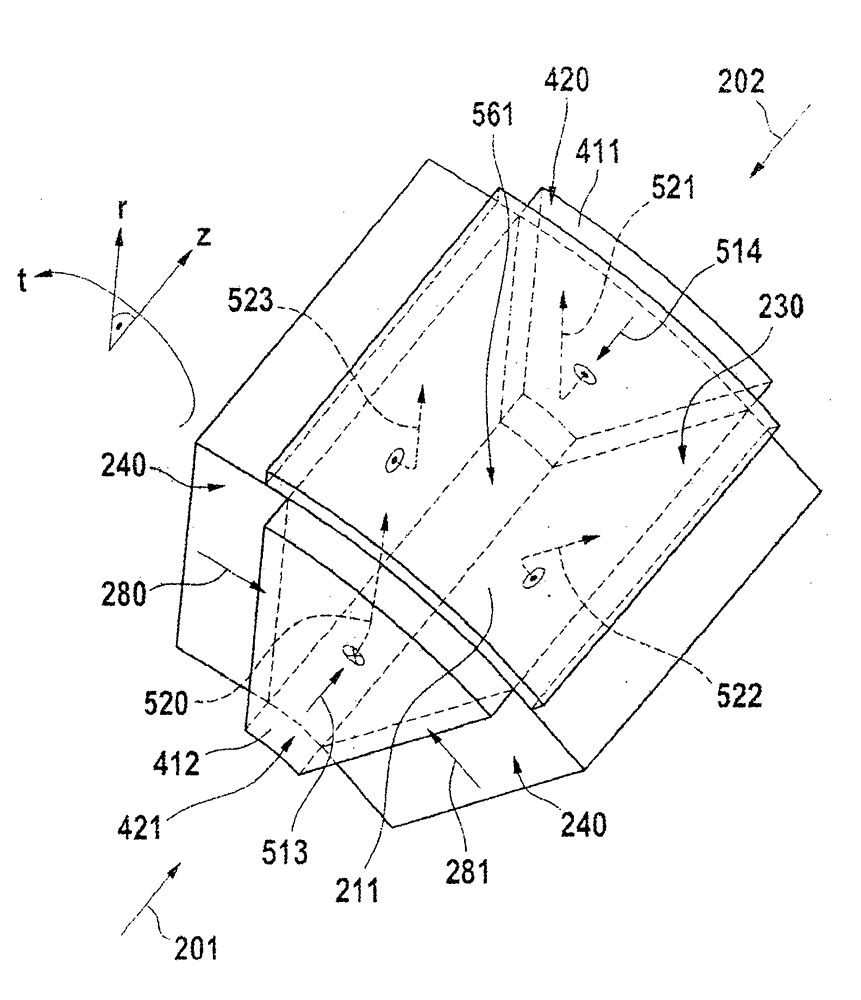

[0040] According to one specific embodiment, the rotor core 300 has a plurality 210 of pole shoes 211 , 212 which preferably form a plurality 231 of recesses 230 oriented at least approximately in the manner of spokes for accommodating a plurality of permanent magnets 240 . However, it should be pointed out that the plurality 231 of recesses 230 is arranged here in a spoke-like manner only for illustration and not as a limitation of the invention, and can alternatively be formed on rotor core 300 in any other manner. The permanent magnet 240 is preferably glued and / or clamped or pressed into the recess 230 . Depending on the type of bulk magnet, permanent magnet 240 preferably consists of a rare earth-free material, but can alternatively also comprise rare earth material.

[0041] According to one specific embodiment, at least one preferably disk-shaped or plate-shaped multipole magnet 250 , 290 , which is referred to below as a “disk magnet” for simplicity of description, is ...

no. 1 approach

[0045] explanatory in image 3 A disk magnet 250 , 290 is respectively arranged on each end side 201 , 202 of rotor core 300 . According to a first embodiment, each of the disk magnets 250 , 290 has a disk-shaped base body 399 , 398 with a plurality 342 of disk segments 340 , 341 , wherein the plurality of disk segments 340 , 341 Each disk segment in is made up of one permanent magnet in a plurality 322 of permanent magnets 320,321. The plurality 322 of permanent magnets 320 , 321 preferably has an even number of permanent magnets 320 , 321 which corresponds to the predetermined number of pole shoes 211 , 212 of rotor core 300 or the number of permanent magnets 240 .

[0046] By way of explanation, permanent magnet 320 for forming disk segment 340 has a magnetic north pole on its end face facing away from rotor core 300 , and permanent magnet 321 for forming disk segment 341 has a magnetic south pole. Overall, the plurality 322 of permanent magnets 320 , 321 form the disk ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com