Tyre inner liner

A technology for inner linings and tires, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as mechanical properties decline, damage to composition, air tightness damage, etc.

Active Publication Date: 2015-06-10

MICHELIN & CO (CIE GEN DES ESTAB MICHELIN)

View PDF14 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, large amounts of these reinforcing fillers impair the composition in the uncured state: difficulty in processing uncured compositions, commonly referred to as "processing" difficulties, and in the cured state: reduction in mechanical properties, especially some properties of flexural strength

The introduction of oil-based plasticizers made it possible to overcome these processing and mechanical performance aspects, but the damage to airtightness was very large

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] The invention and its advantages are readily understood from the following description and exemplary embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

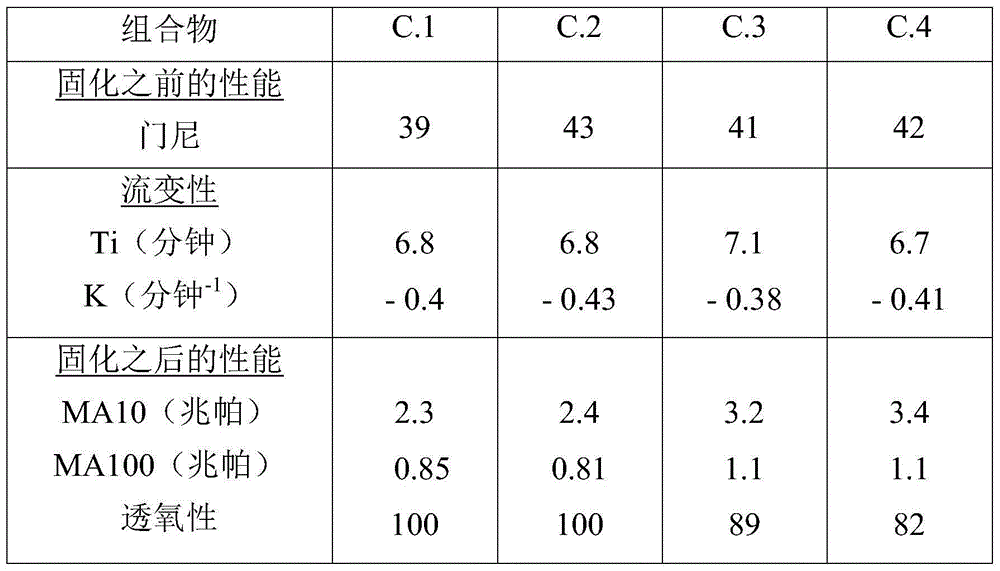

The present invention concerns a tyre of which the inner liner comprises a rubber composition made at least principally from a highly unsaturated diene elastomer, a reinforcing organic filler, graphite, chalk, and a hydrocarbon plasticising resin of which the vitreous transition temperature, Tg, is higher than 20°C and the softening temperature is lower than 170°C. Using such a composition in the tyre inner liner, including graphite and a non-reinforcing chalk filler, makes it possible to considerably improve the sealing properties relative to a control composition that comprises only graphite and that already offers an excellent performance in this respect, but also relative to a control composition conventionally used in tyre inner liners, while keeping the properties of rigidity and processability as high-level as conventional control compositions.

Description

technical field [0001] This invention relates to rubber compositions useful in the manufacture of airtight tire inner layers, commonly referred to as tire "liners". Background technique [0002] Tubeless tires have an inner surface with low air permeability to prevent the tire from deflating and to protect sensitive inner areas of the tire from the ingress of oxygen and water, such as the carcass plies containing oxidation-sensitive metal cords, such Protection improves the durability of the tire. Currently, this protection of the inner surface of the tire is achieved by an innerliner composed of an elastomeric composition based on butyl rubber. However, the airtight properties of butyl rubber are linked to a non-negligible minimum thickness (of the order of millimeters) and thus to a certain weight, which does not make it possible to effectively meet these new demands. [0003] Therefore, there is a need to add reinforcing fillers such as carbon black to elastomeric inner...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L7/00C08L9/00C08L9/06C08L53/02C08K3/04C08K3/26

CPCB60C1/0008C08L9/06C08L2205/035C08L2205/025C08K2201/014C08L91/00C08L57/02C08K13/02C08K3/04C08K2003/2296C08L21/00C08L53/02C08K3/26C08L2205/05

Inventor I·里乌A·里乌J-L·卡比奇

Owner MICHELIN & CO (CIE GEN DES ESTAB MICHELIN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com