A two-stage microneedle array and its preparation method

A needle array and microneedle technology, applied in the field of two-segment microneedle array and its preparation, can solve the problems of long-term use of drugs and the inability of drugs to be absorbed quickly, and achieve the effect of reducing operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

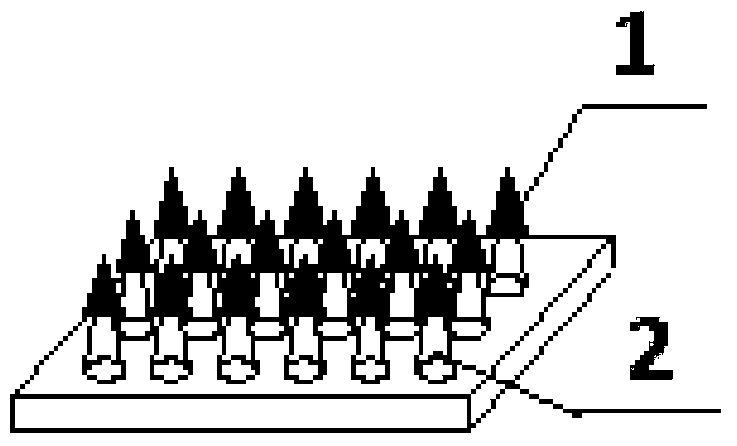

[0021] A two-stage microneedle array, the two-stage microneedle array includes a lower microneedle base and an upper tip of the microneedle; the upper tip of the microneedle is a raised structure with a cavity, and the lower base of the microneedle It has a matching protrusion structure that can be inserted into the cavity of the tip of the upper section of the microneedle; the preparation material of the base of the lower section of the microneedle is a biodegradable insoluble polymer material; the tip of the upper section of the microneedle is used to carry drugs , and its preparation materials include biodegradable soluble polymer materials; the insoluble polymer material is polylactic acid; the soluble polymer material is polyvinyl alcohol; the drug is insulin, and its loading method is to concentrate the drug on The top of the tip of the upper section of the microneedle; the preparation material of the tip of the upper section of the microneedle also includes a stabilizer,...

Embodiment 2

[0024] A two-stage microneedle array, the two-stage microneedle array includes a base of the lower section of the microneedle and a tip of the upper section of the microneedle; the tip of the upper section of the microneedle is a conical structure with a cavity, and the lower section of the microneedle base It has a matching protrusion structure that can be inserted into the cavity of the tip of the upper section of the microneedle; the preparation material of the base of the lower section of the microneedle is a biodegradable insoluble polymer material; the tip of the upper section of the microneedle is used to carry drugs The preparation materials include biodegradable soluble polymer materials; the insoluble polymer material is polylactic acid; the soluble polymer material is polyvinyl alcohol; the drug is rabies vaccine, and its carrying mode is to concentrate the drug At the top of the tip of the upper section of the microneedle; the preparation material of the tip of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com