Passenger room baggage rack installation technology of railway vehicle

A technology of rail vehicles and installation technology, which is applied in the direction of transportation and packaging, railway car body parts, etc., can solve the unfavorable demand for vehicle weight reduction, reduce the vehicle's interior aesthetic performance, and the weight of a single piece, etc., to achieve a good market Foreground, avoid crowding, good installation quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

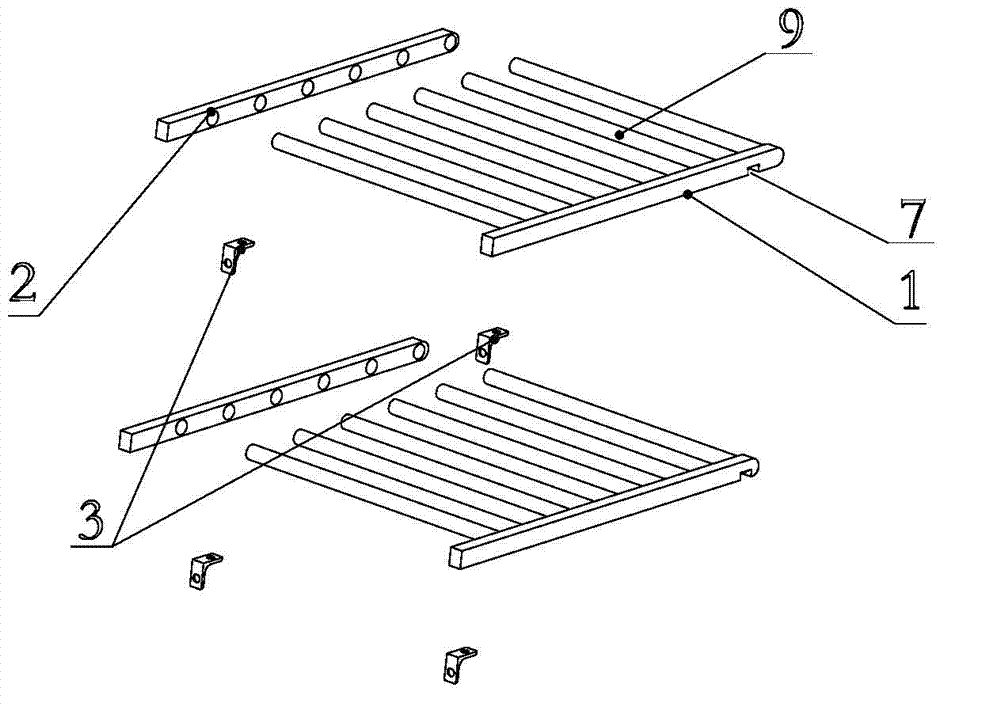

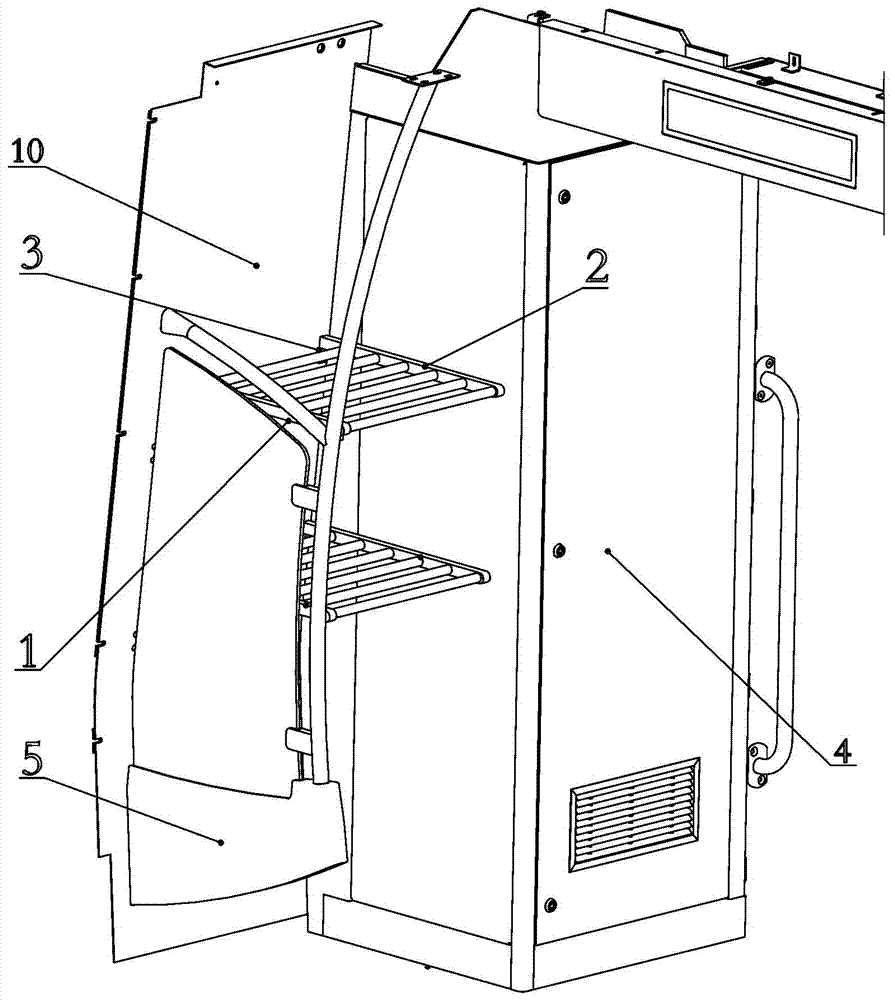

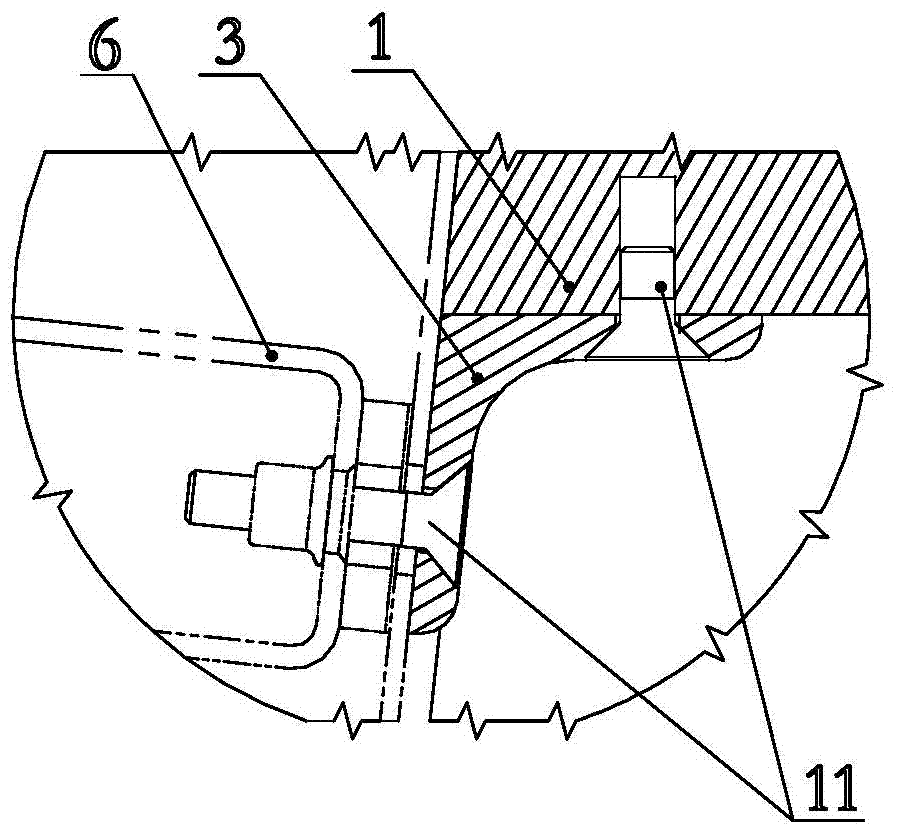

[0032] Such as Figure 1 to Figure 6 As shown, it is the rail car passenger room luggage rack to be installed in this embodiment. The luggage rack has a double-layer structure and is installed between the electric cabinet 4 at the vehicle end and the screen 5. The composition of each layer includes: the first side frame 1, The second side frame 2 and a number of crossbars 9 inserted and fixed between the first side frame 1 and the second side frame 2; the lower parts of the outer ends of the first side frame 1 and the second side frame 2 are fixed with mounting brackets 3. The mounting bracket 3 is connected with the vehicle side wall frame 6 between the vehicle end electrical cabinet 4 and the screen 5 through screws; the lower part of the inner end of the first side frame 1 is provided with a groove 7, and the corresponding position of the screen frame is welded with a bump 8, the convex The block 8 is embedded in the groove 7, and the inner end of the first side frame 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com