A support plate fixing structure and a shell-and-tube heat exchanger having the same

A shell-and-tube heat exchanger and fixed structure technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of inability to remove welding slag, easy to block the central air conditioning system, difficult operation and other problems , to achieve the effect of improving connection stability and installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

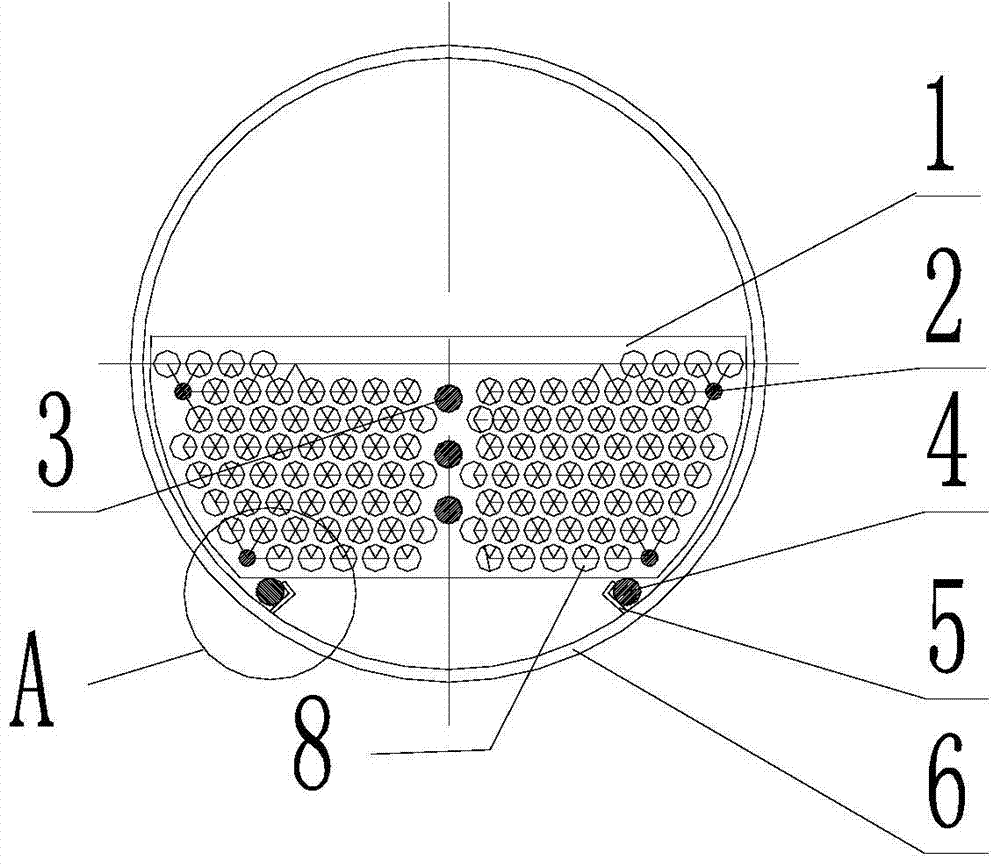

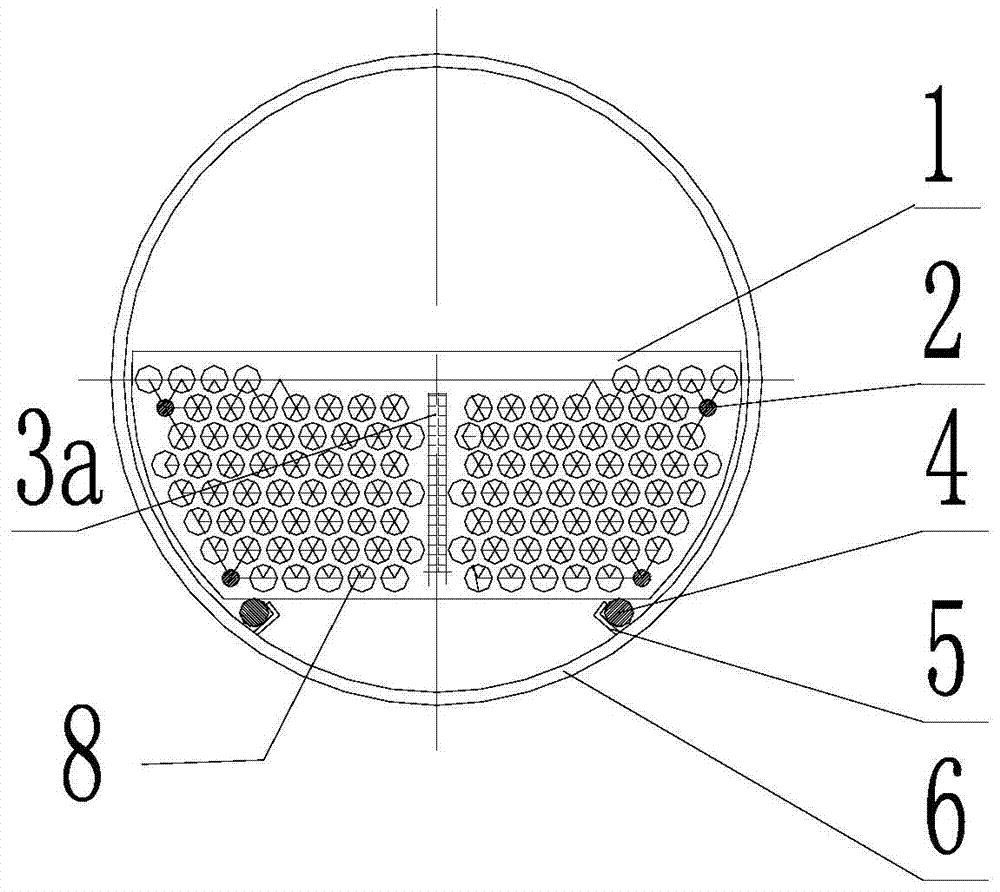

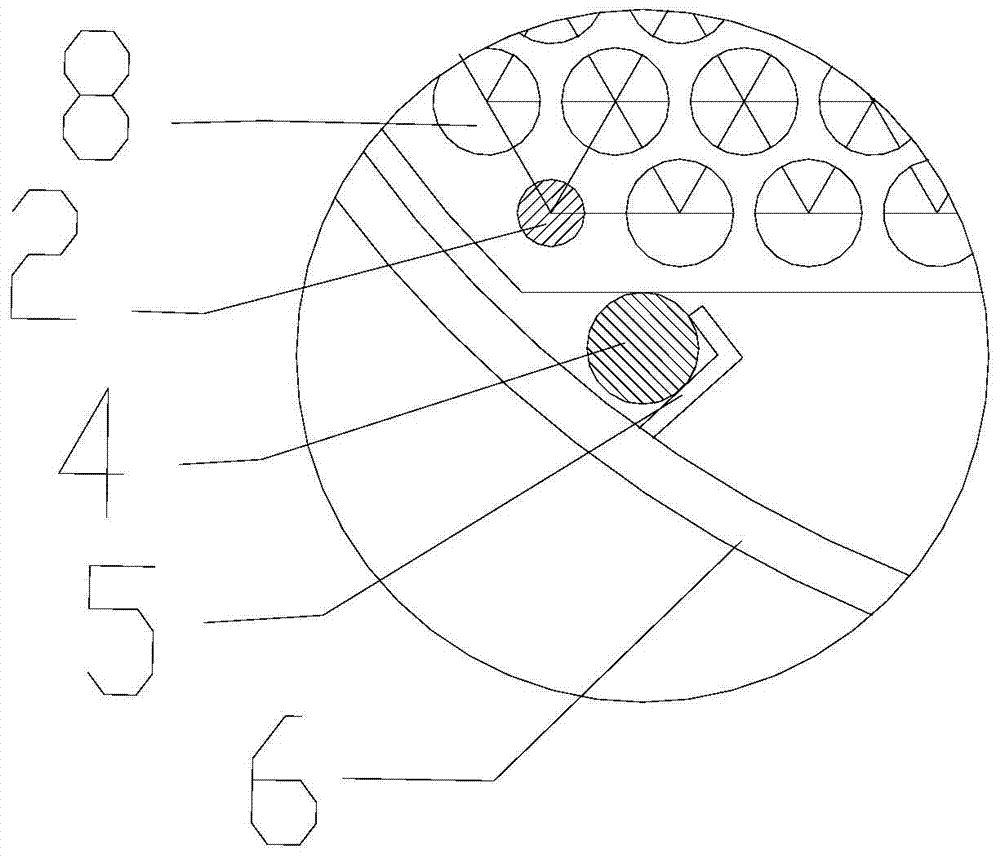

[0020] Such as Figures 1 to 3 As shown, a support plate fixing structure includes a support plate 1 and a housing 6, the support plate 1 is arranged in the housing 6, a slide bar 4 is fixedly arranged on the support plate 1, and the inner side of the housing 6 Fixing strips 5 are fixedly arranged on the wall. The sliding rod 4 elastically cooperates with the fixing bar 5 to fix the support plate 1 and the housing 6 . During assembly, the slide bar 4 is first welded to the bottom of the support plate 1 , and the fixing strip 5 is welded to the inner side of the housing 6 . In order to omit manually climbing into the inside of the housing 6 for welding, the fixing strip 5 can be welded near both ends of the housing 6, and of course the middle part can also be fixed by other fixing structures. Due to the gravity exerted by the support plate 1, the slide bar 4 cooperates with the fixing bar 5 to produce deformation, so that the support plate 1 and the housing 6 are relatively f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com