Detecting method of bearing inner ring hole diameter detecting device

A technology of bearing inner ring and detection device, applied in the direction of measurement device, electromagnetic measurement device, electric device, etc., can solve problems such as error and affect measurement accuracy, and achieve the effect of saving cost, ensuring measurement accuracy and improving system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

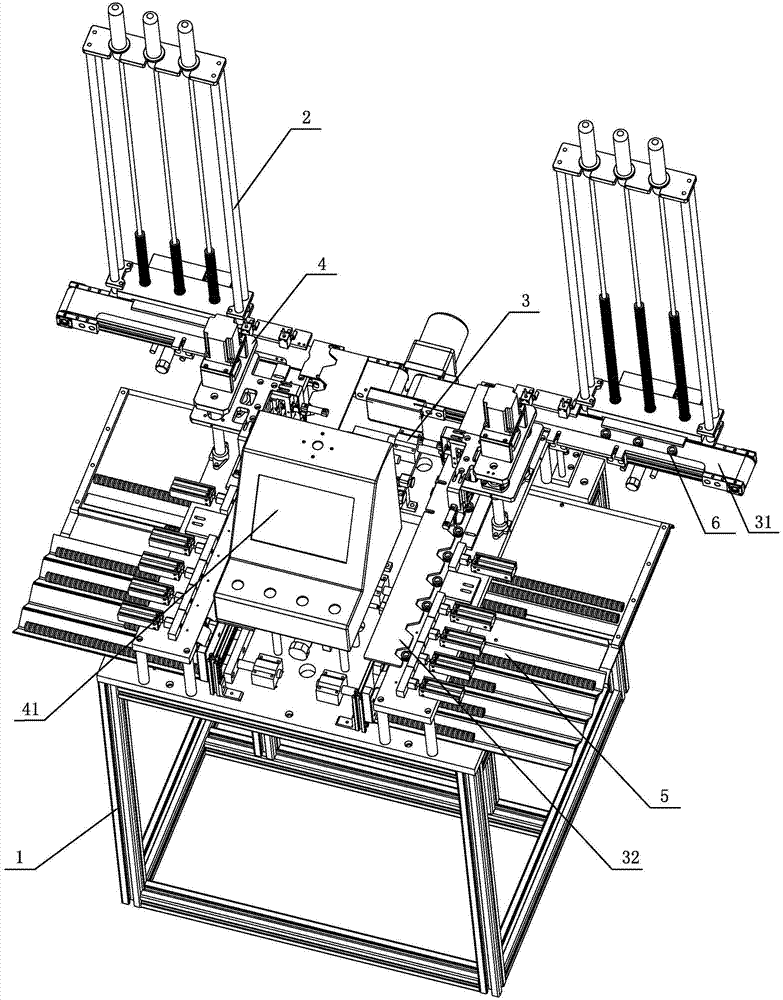

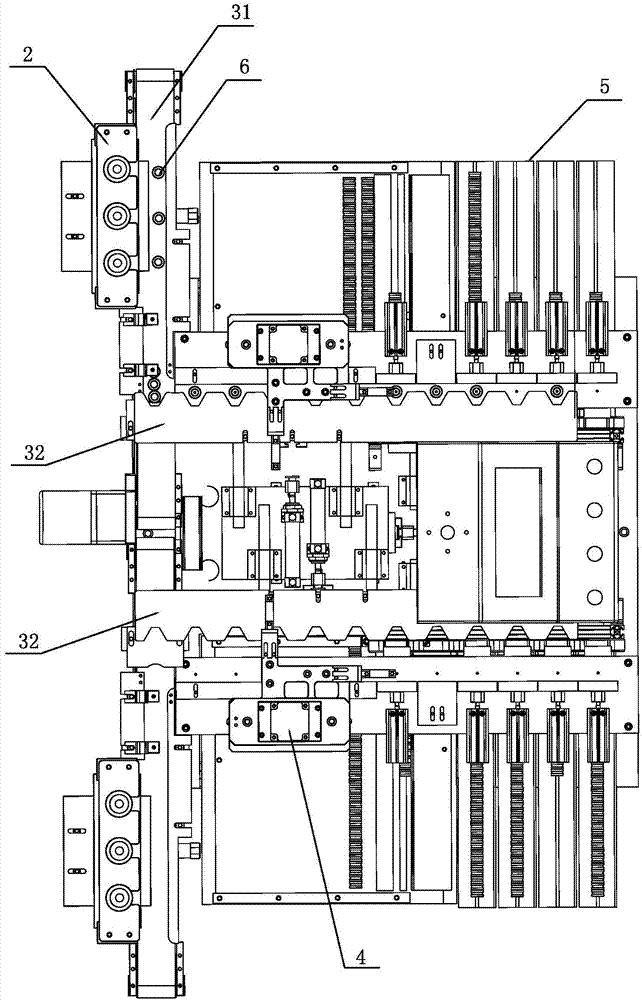

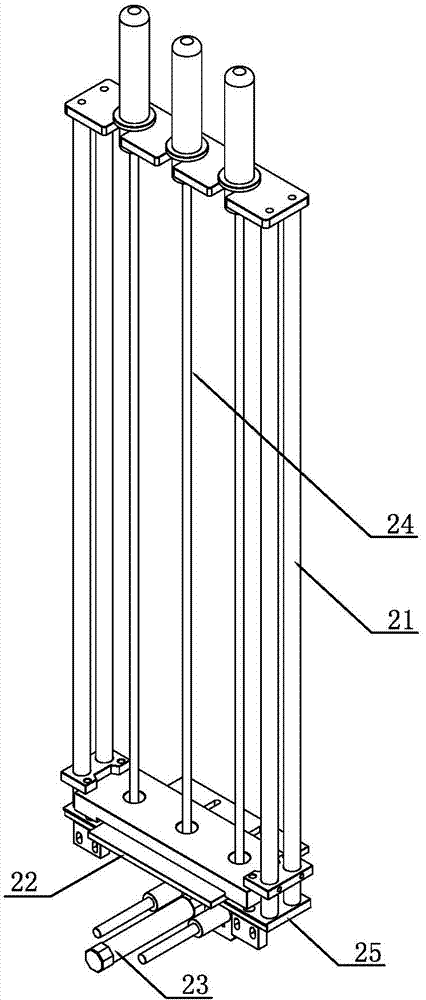

[0054] Such as Figure 1-2 As shown, a bearing inner ring aperture detection device includes a base 1, and two sets of symmetrical feeding mechanism 2, transfer mechanism 3, detection mechanism 4 and discharge mechanism 5 installed on the base 1, wherein, two The transfer mechanism 3 is installed side by side on the base 1, the feeding mechanism 2 is installed on the side of the conveyor belt 31 of the transfer mechanism 3, the detection mechanism 4 is installed on the side of the shift piece 32 of the transfer mechanism 3, and the discharge mechanism 5 is located on the shift piece 32 Below, the bearing inner ring 6 to be tested on the feeding mechanism 2 is transported to the detection mechanism 4 through the conveyor belt 31 and the displacement piece 32, and then moved into the discharge mechanism 5 through the displacement piece 31 after detection; the device further includes a control unit, the control unit is respectively connected with the feeding mechanism 2, the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com