A cable shovel

A technology for shoveling boards and cables, applied in the direction of lifting devices, etc., can solve problems such as cable trays and loading, and achieve the effects of simple structure, convenient loading/unloading of cables, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

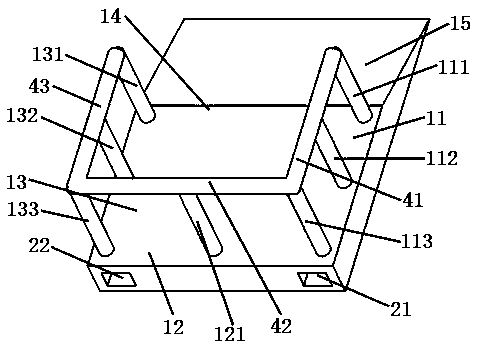

[0026] please see figure 1 , a cable shovel, is characterized in that it comprises a pressure-resistant plate, a slope 15 connected to the front side 14 of the pressure-resistant plate, three first-type retaining strips of equal height installed on the right side surface 11 of the pressure-resistant plate, Three second-type retaining bars with equal heights installed on the left side surface 13 of the pressure-resistant plate, three equal-height third-type retaining bars installed on the pressure-resistant plate rear surface 12, the first limit bar 41, the second limit bar Position strip 43 and the third limit strip 42; the first limit strip is located at the upper end of the first type of dam strip and connects the first type of dam strip together, and the second limit strip is positioned at the upper end of the second type of dam strip and connects the second The third limit bar is located at the upper end of the third type bar and the third bar is connected together, one en...

Embodiment 2

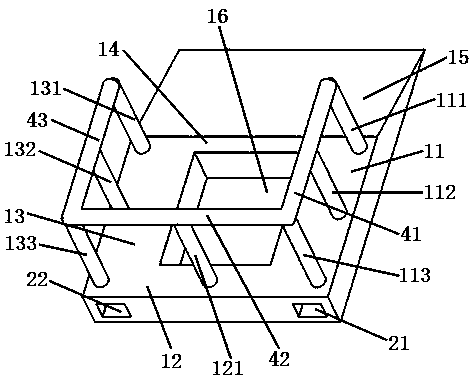

[0029] please see figure 2, a cable shovel, is characterized in that it comprises a pressure-resistant plate, a slope 15 connected to the front side 14 of the pressure-resistant plate, three first-type retaining strips of equal height installed on the right side surface 11 of the pressure-resistant plate, Three second-type retaining bars with equal heights installed on the left side surface 13 of the pressure-resistant plate, three equal-height third-type retaining bars installed on the pressure-resistant plate rear surface 12, the first limit bar 41, the second limit bar Position strip 43 and the third limit strip 42; the first limit strip is located at the upper end of the first type of dam strip and connects the first type of dam strip together, and the second limit strip is positioned at the upper end of the second type of dam strip and connects the second The third limit bar is located at the upper end of the third type bar and the third bar is connected together, one en...

Embodiment 3

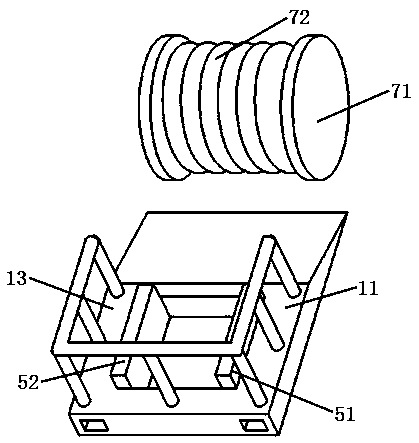

[0032] please see image 3 , and refer to figure 1 and figure 2 , a cable shovel plate, basically the same as the implementation example 2, except that: the right side surface 11 of the pressure-resistant plate has a first limiting plate 51 protruding upward, and the first limiting plate is located on the right side of the middle groove. There is a gap between the first limiting plate and the first type of bar; the left side surface 13 of the pressure-resistant plate has a second limiting plate 52 protruding upwards, and the second limiting plate is located on the left side of the middle groove. On the side, there is a gap between the second limiting plate and the second type of bar.

[0033] When shipping the cable reel, push the cable reel up the pressure-resistant plate along the slope, so that the side plate 71 of the cable reel enters the gap between the limit plate and the retaining bar, and the shovel of the forklift enters the first groove and the second groove. Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com