Automatic sample injector for full-automatic thermal desorption instrument, working method of automatic sample injector and full-automatic thermal desorption instrument

A technology of automatic sampling and thermal desorption instrument, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problem of human workload that cannot automatically load and unload adsorption tubes, and achieve the goal of reducing human workload, high efficiency, and saving manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

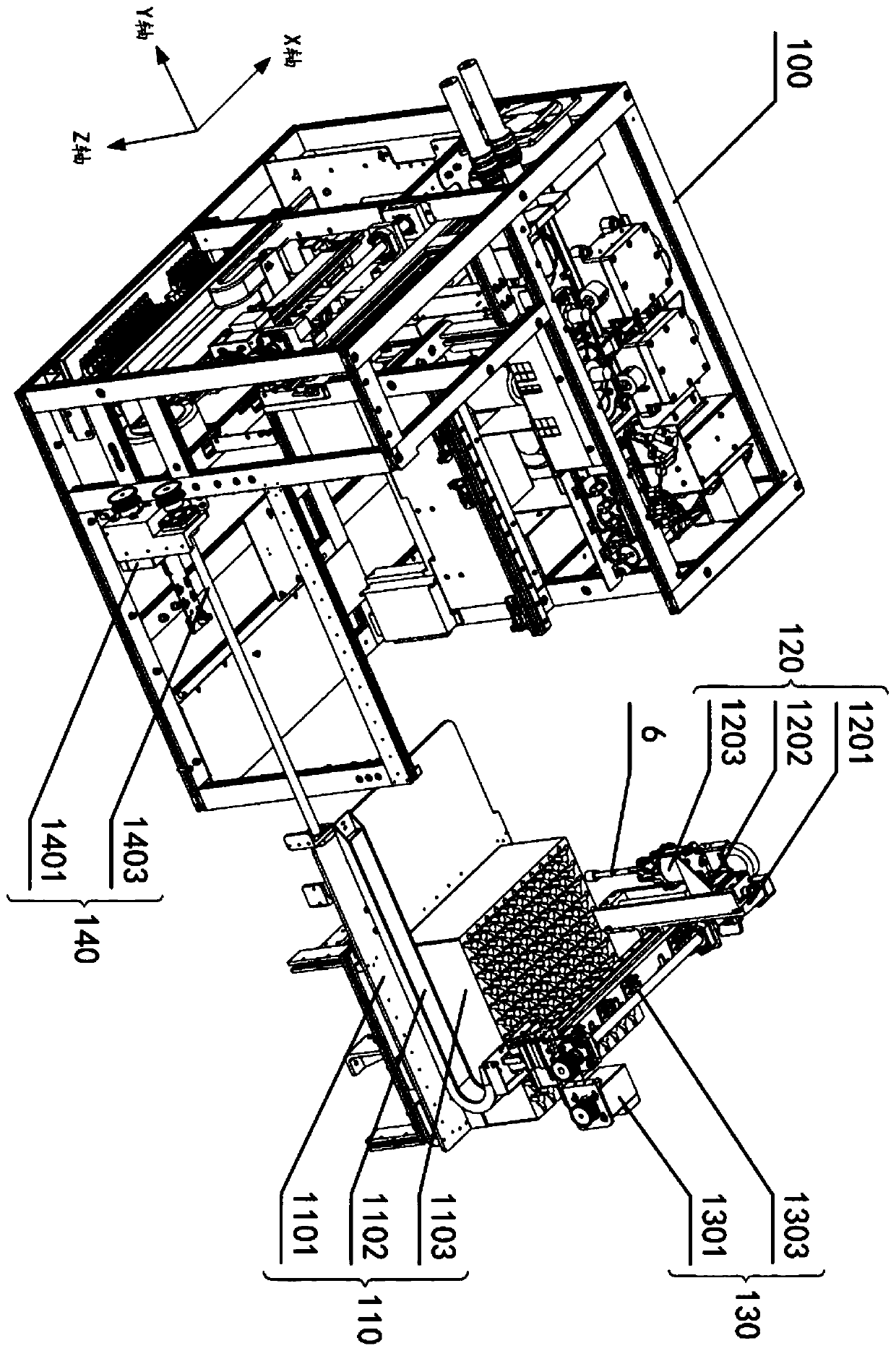

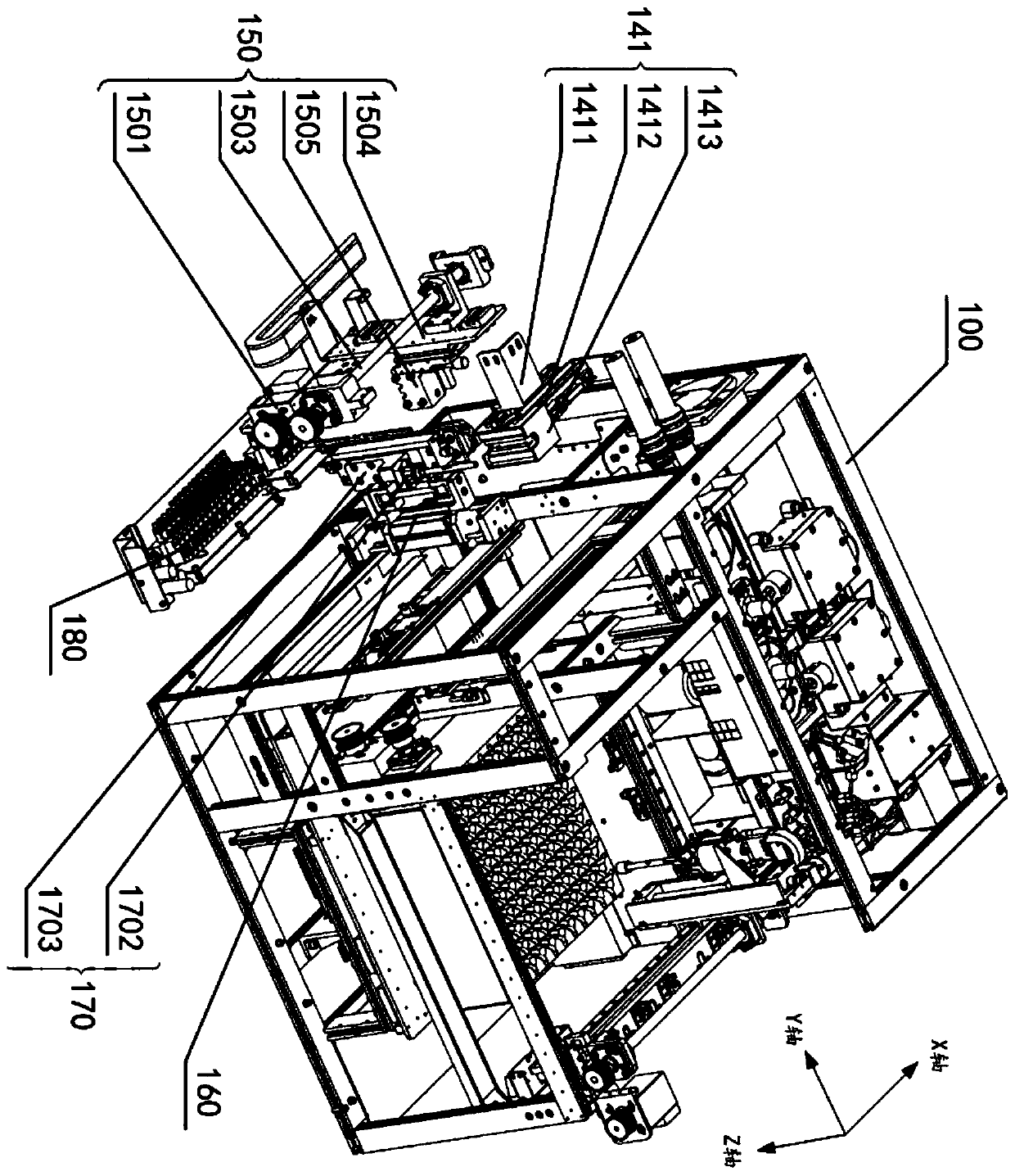

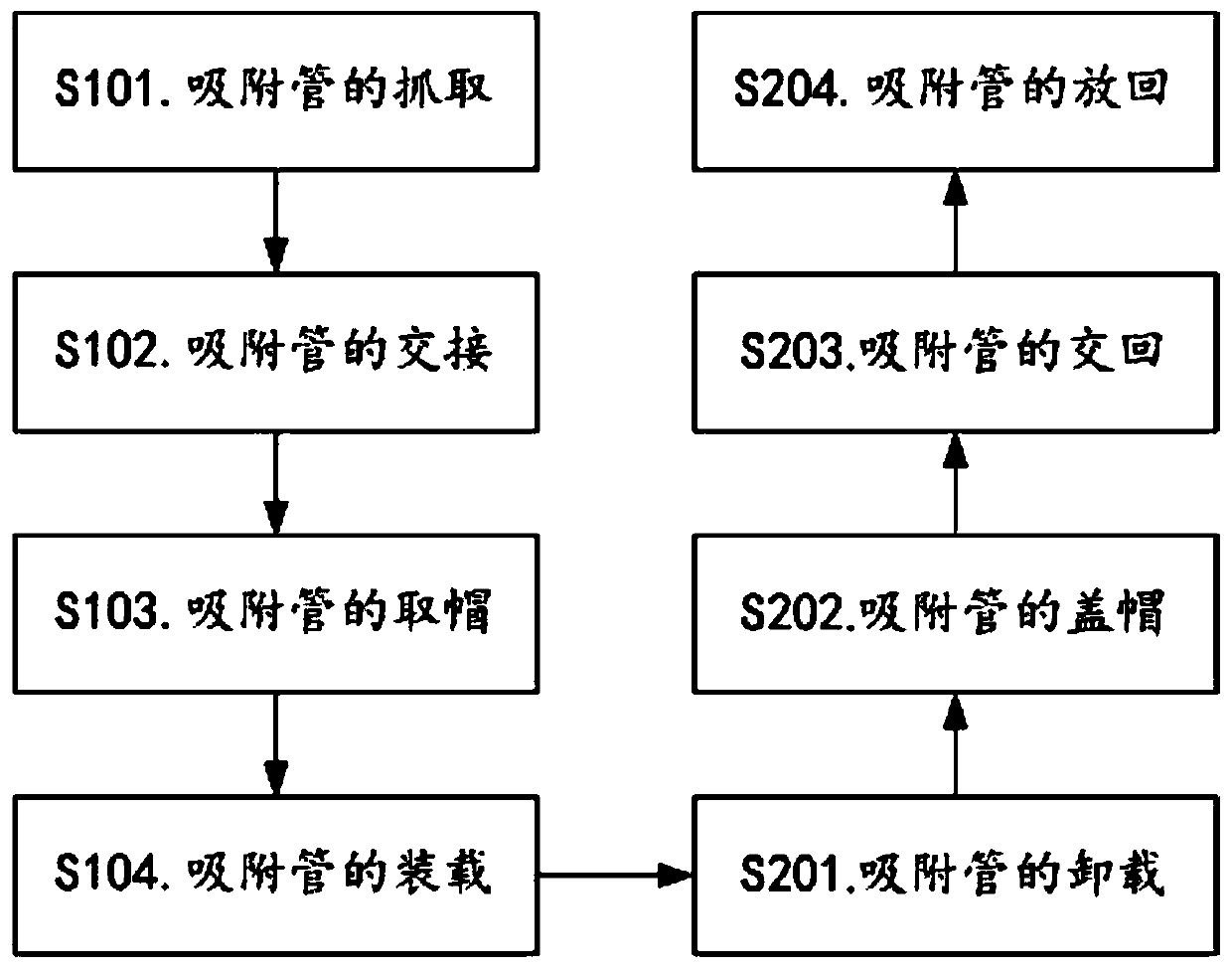

[0079] Such as Figure 1~3 As shown, the autosampler for a fully automatic thermal desorption instrument provided in this embodiment includes a main body support 100, a tray assembly 110, a Z-axis assembly 120, an X-axis assembly 130, and a Y-axis assembly 140. Beam assembly 150, cover removal assembly 160, loading assembly 170 and valve island assembly 180, wherein the Z axis is the vertical axis, the X axis is the horizontal horizontal axis, and the Y axis is the horizontal vertical axis; the pallet assembly The assembly 110 is arranged on the tray station of the main body support 100, and is used to accommodate a plurality of adsorption tubes 6; the Z-axis assembly 120 is arranged on the main body support 100 and is located above the tray assembly 110, It is used to vertically extract the adsorption tube 6 from the tray assembly 110, and vertically put the adsorption tube 6 into the tray assembly 110; the X-axis assembly 130 is arranged on the The main body bracket 100 is ...

Embodiment 2

[0099] Such as figure 1 , 2 As shown in and 4, this embodiment also provides a novel automatic thermal desorption instrument on the basis of the first embodiment, including the automatic sampler for the automatic thermal desorption instrument as described in the first embodiment , also includes a gas circuit assembly and a circuit assembly arranged on the main body bracket 100; the gas circuit assembly includes a nitrogen joint 1, a first mass flow controller 201, a second mass flow controller 202, multiple Through switching valve 3, first electromagnetic switching valve 401, second electromagnetic switching valve 402, first emptying joint 501, second emptying joint 502, third emptying joint 503, sample recovery tube 7, eight-way switching valve 8 , a temperature-controlled dehydration pipe 9, a temperature-controlled focusing tube 10, a carrier gas inlet and outlet pipeline 11, a proportional valve 12, and a pressure sensor 13; the nitrogen connector 1 is connected to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com