Method for creating digital radiographic inspection model for weld defects

A digital ray, detection model technology, applied in image data processing, instrumentation, calculation and other directions, can solve the problems of poor image effect, can not meet the requirements of high recall rate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

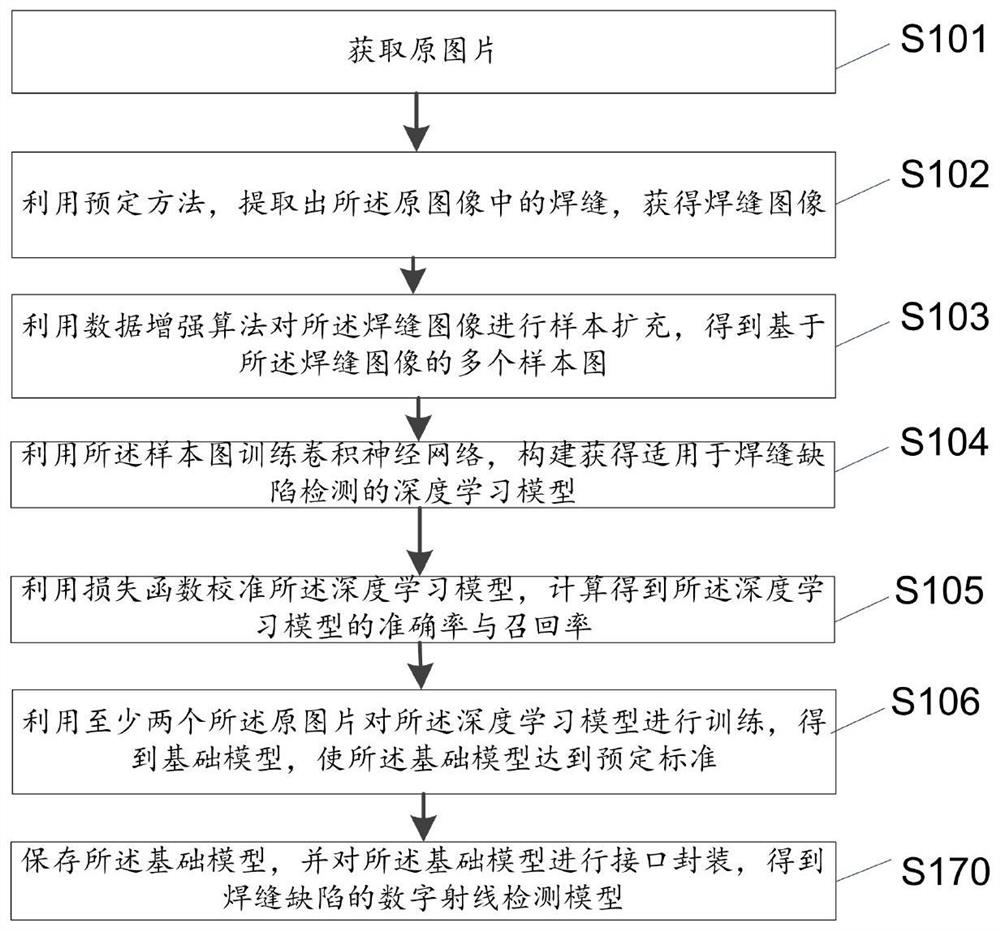

[0055] See figure 1 , an embodiment of the present invention provides a method for creating a digital ray detection model of weld defects, including:

[0056]S110. Obtain the original picture; the above original picture can be obtained directly from the database. Specifically, in this application, the above original picture is the original picture with welds. Specifically, whether the above welds are defective can be used as the above original picture of this solution .

[0057] S120. Using a predetermined method, extract the weld seam in the original image to obtain a weld seam image.

[0058] S130. Use a data enhancement algorithm to expand the sample of the weld image to obtain multiple sample images based on the weld image; use a data enhancement algorithm to expand the existing positive and negative samples, thereby increasing the capacity of the sample . According to the characteristics of the weld image, the original weld image is expanded by using image flip symmetr...

Embodiment 2

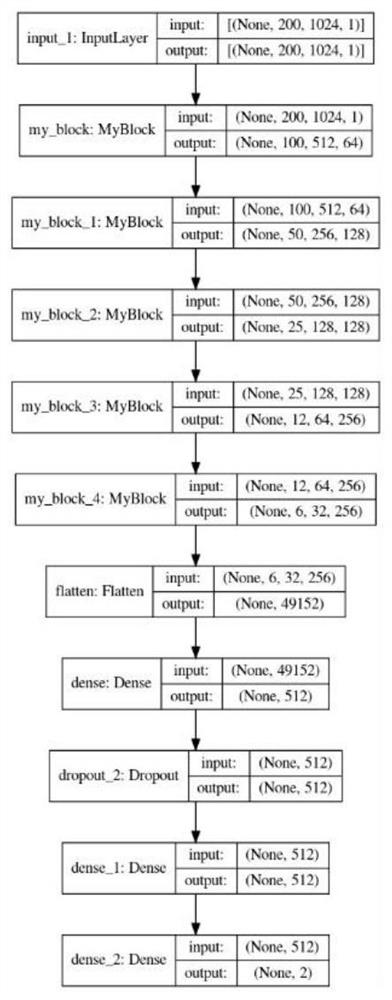

[0071] On the basis of the above-mentioned embodiment 1, this embodiment combines Figure 2-Figure 15 , to further describe the scheme in detail. details as follows:

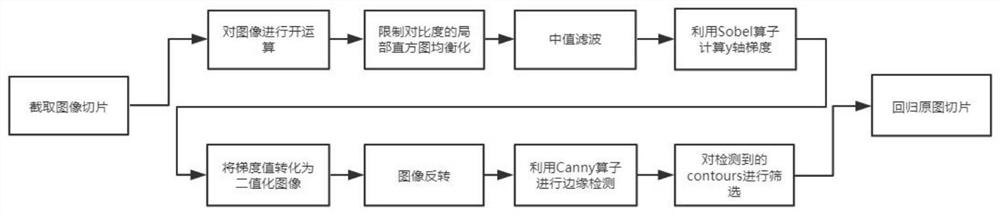

[0072] Further, the predetermined method is:

[0073] Obtaining the region of interest of the original picture, and outlining the region of interest;

[0074] The image of the weld seam is extracted from the region of interest by using an edge detection method.

[0075] Specifically, the first step is to extract the region of interest from the image, that is, the weld.

[0076] Very important in image processing is ROI (region of interest), the region of interest. In machine vision and image processing, the area to be processed is outlined from the processed image in the form of a box, circle, ellipse, irregular polygon, etc., which is called the region of interest, ROI. Various operators (Operator operation symbols) and functions are commonly used in machine vision software such as Halcon, OpenCV, and Matl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com