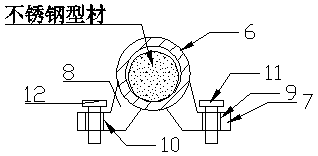

Finishing structure for round stainless steel pipe

A stainless steel, circular technology, applied in the direction of grinding workpiece support, etc., to achieve the effect of improving finishing efficiency, stable and precise fixed operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

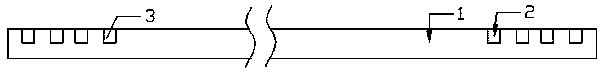

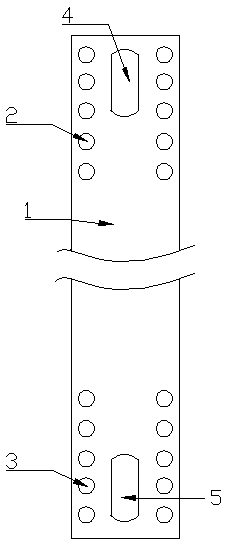

[0015] Such as figure 1 , figure 2 , image 3 with Figure 4 The shown finishing structure for circular stainless steel pipes consists of a strip bottom plate 1, and several groups of first vertical internal threaded holes 2 and several groups of second vertical internal thread holes symmetrically arranged in the end faces of the two ends of the strip bottom plate 1. Internally threaded holes 3, and the first waist-shaped fixing through grooves 4, which are respectively arranged in the end faces of the two ends of the strip bottom plate 1 and are located between several groups of first vertical internally threaded holes 2 and several groups of second vertically internally threaded holes 3, The second waist-shaped fixed through slot 5 is composed of a first support limiting component and a second supporting limiting component used in conjunc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com