Automobile front wall connecting plate welding tool

A welding tooling and connecting plate technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient fixture size adjustment, inability to adapt to the connecting plate, and reduce work efficiency, so as to achieve fast fixed work , Convenient installation and disassembly work, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

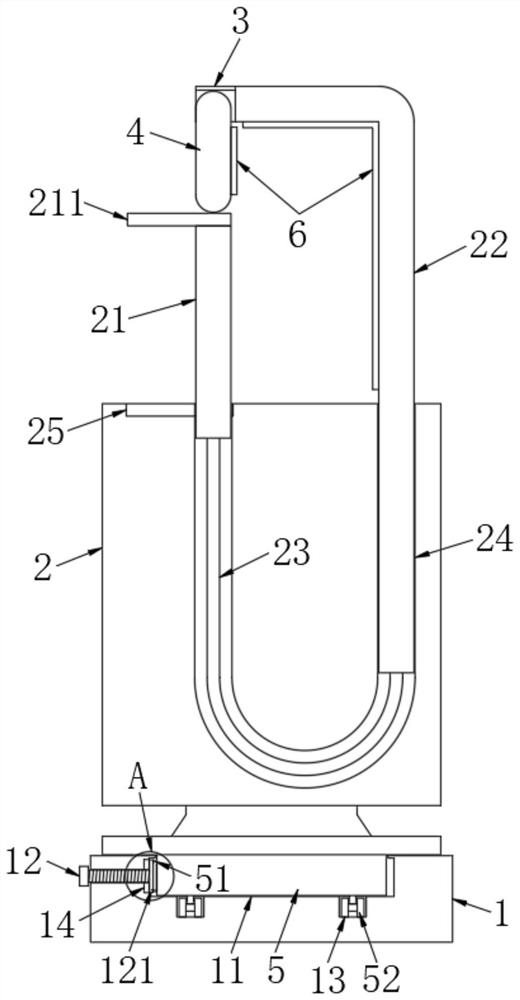

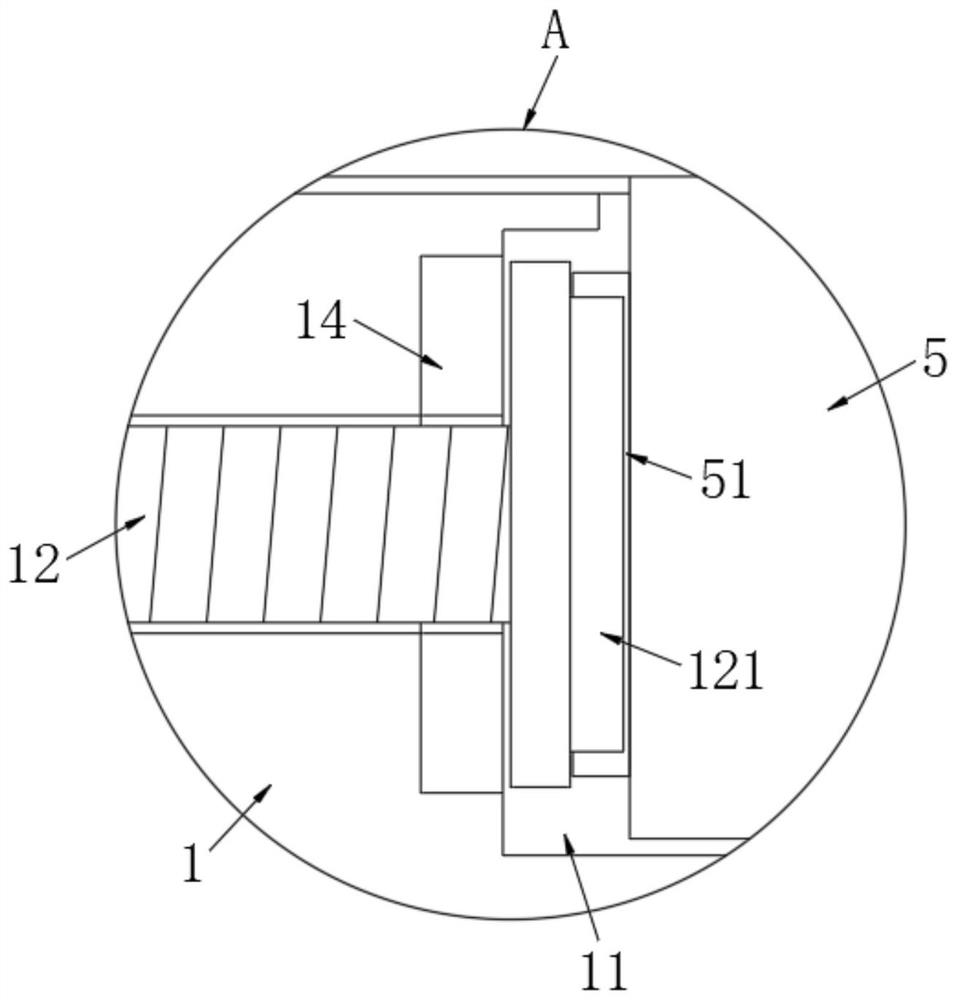

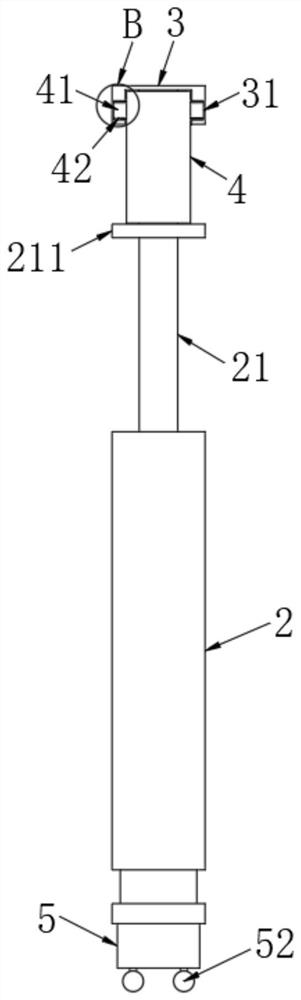

[0027]SeeFigure 1-5The present invention provides a technical solution for welding tooling for the front wall connecting plate of an automobile: it includes a base 1, a support plate 2 is slidably installed on the top of the base 1, and a symmetrically distributed compression rod 21 and a top rod 22 are slidably installed inside the support plate 2. The rod 21 is located in front of the top rod 22, a connecting bar 23 is fixedly connected between the bottom end of the pressing rod 21 and the bottom end of the top rod 22, a U-shaped groove 24 is opened inside the pallet 2, the pressing rod 21, the top rod 22 and the connecting bar 23 They are all located inside the U-shaped groove 24, the end of the top rod 22 away from the connecting bar 23 is fixedly connected with a mounting frame 3, the mounting frame 3 is hinged with a block 4, which is located directly above the pressure rod 21, and the top of the base 1 is provided with a movable Slot 11, the front and rear ends of the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com