Double-enzyme method for improving specificity of gamma-cyclodextrin

A cyclodextrin, specific technology, applied in the direction of fermentation, etc., can solve the problem of low specificity of γ-cyclodextrin, and achieve the effect of improving the specificity and increasing the catalytic temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve cornstarch in 50ml of Tris-Hcl buffer solution with a pH of 8.5 and a concentration of 50mmol / l to make a 1% solution, and heat it with microwave for 2-3min to gelatinize it.

[0024] (2) Take 1ml of the solution prepared in (1), first add 0.1U / g starch 4αGTase to react at 70°C for 24h to pretreat corn starch, and then add 0.5U / g starch CGTase to the reaction system at 60 Reaction at ℃ for 24h.

[0025] (3) Boil the reaction solution in step (2) to inactivate it for 30 minutes.

[0026] (4) Mix 500 ul of the reaction solution in step (3) with 500 ul of 0.2 M sodium acetate buffer solution at pH 4.2, and add 0.4 U / g starch glucoamylase to it and react at 38° C. for 16 h.

[0027] (5) Boil the reaction solution obtained in step (4) for 10 minutes to inactivate the enzyme, and centrifuge at 18000 g for 5 minutes after inactivating the enzyme.

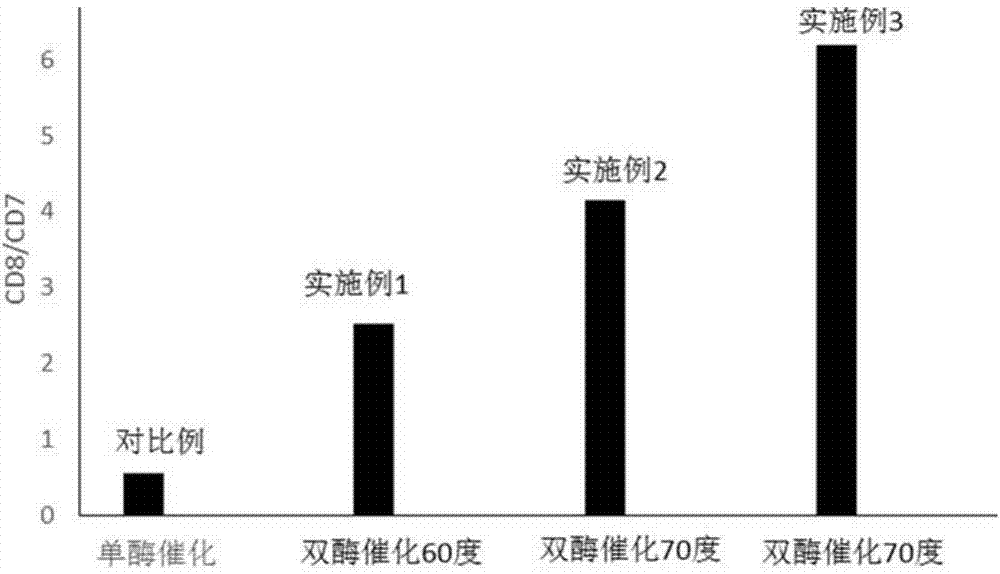

[0028] (6) The cyclodextrin solution measured in the above steps was measured, and the ratio of γ-cyclodextrin / β-cy...

Embodiment 2

[0030] (1) Dissolve cornstarch in 50ml of Tris-Hcl buffer solution with a pH of 8.5 and a concentration of 50mmol / l to make a 1% solution, and heat it with microwave for 2-3min to gelatinize it.

[0031] (2) Take 1ml of the solution prepared in (1), first add 0.1U / g starch 4αGTase to react at 70°C for 24h to pretreat corn starch, and then add 0.5U / g starch CGTase to the reaction system at 70°C Under reaction 24h.

[0032] (3) Boil the reaction solution in step (2) to inactivate it for 30 minutes.

[0033] (4) Mix 500 ul of the reaction solution in step (3) with 500 ul of 0.2 M sodium acetate buffer solution at pH 4.2, and add 0.4 U / g starch glucoamylase to it and react at 38° C. for 16 h.

[0034] (5) Boil the reaction solution obtained in step (4) for 10 minutes to inactivate the enzyme, and centrifuge at 18000 g for 5 minutes after inactivating the enzyme.

[0035] (6) The cyclodextrin solution measured in the above steps was measured, and the ratio of γ-cyclodextrin / β-cyc...

Embodiment 3

[0037] (1) Dissolve cornstarch in 50ml of Tris-Hcl buffer solution with a pH of 8.5 and a concentration of 50mmol / l to make a 1% solution, and heat it with microwave for 2-3min to gelatinize it.

[0038] (2) Take 1ml of the solution prepared in (1), first add 0.05U / g starch 4αGTase to react at 70°C for 24h to pretreat corn starch, and then add 0.5U / g starch CGTase to the reaction system at 70 Reaction at ℃ for 24h.

[0039] (3) Boil the reaction solution in step (2) to inactivate it for 30 minutes.

[0040] (4) Mix 500 ul of the reaction solution in step (3) with 500 ul of 0.2 M sodium acetate buffer solution at pH 4.2, and add 0.4 U / g starch glucoamylase to it and react at 38° C. for 16 h.

[0041] (5) Boil the reaction solution obtained in step (4) for 10 minutes to inactivate the enzyme, and centrifuge at 18000 g for 5 minutes after inactivating the enzyme.

[0042] (6) The cyclodextrin solution measured in the above steps was measured, and the ratio of γ-cyclodextrin / β-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com