Assembly concrete new type pillar and beam structure and assembly connecting method

A technology for concrete and beam structures, which is applied in the field of beam structures and assembly connections, as well as in the field of prefabricated concrete new columns, which can solve the problems of inability to realize shear connections such as prefabricated columns, large amount of connection sleeves, and high project cost, so as to reduce the quantity, The effect of economical connection and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

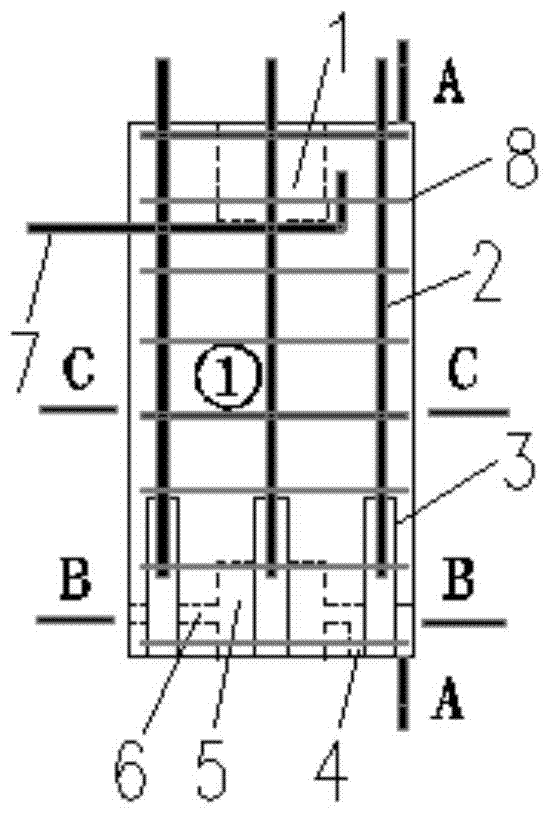

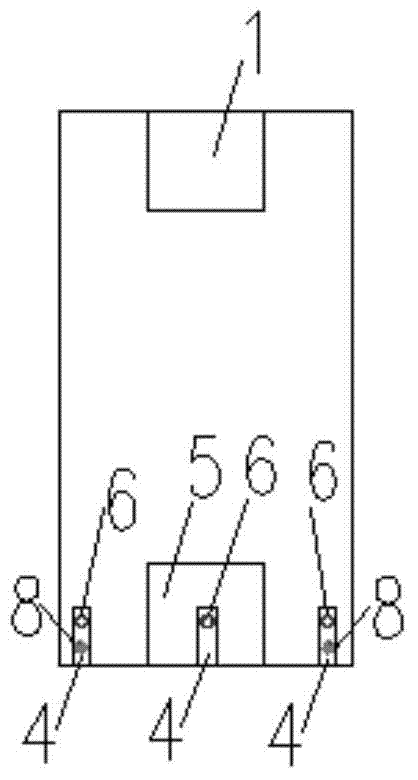

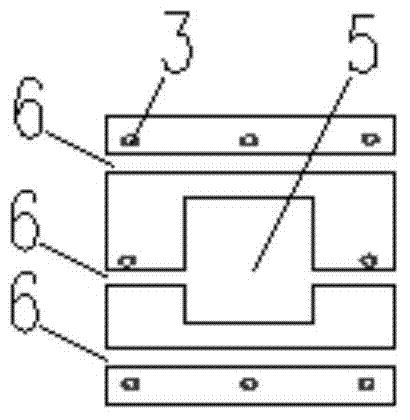

[0046] Such as Figure 1-Figure 4 As shown, the prefabricated side column of the present invention ①: the top is provided with column top grouting groove 1; the interior is equipped with column longitudinal reinforcement 2, and the lower end of column longitudinal reinforcement extends into column sleeve 3; the bottom is provided with column bottom grouting groove 5, and the outer side of the bottom The side column piercing groove 4 is provided, and the top of the side column piercing groove 4 is provided with the beam piercing steel hole 6 through the column; The butt joint reinforcement 7 extends to one end of the prefabricated side column ① and bends along the outside of the grouting groove 1 on the top of the column, and the other end of the side column is reserved to connect with the steel bar at the bottom of the beam 7 extends out of the prefabricated side column ① along the transverse direction; along the prefabricated side column ① In the height direction, there are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com